A kind of aluminum-silicon alloy of rheological die-casting heat dissipation shell and its preparation method

A technology of aluminum-silicon alloy and heat-dissipating shell, which is applied in the field of aluminum-silicon alloy and its preparation, can solve the problems of heat dissipation performance deviation, high thermal conductivity, and large volume of the heat-dissipating shell, so as to ensure uniformity, meet fluidity requirements, The effect of efficient preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

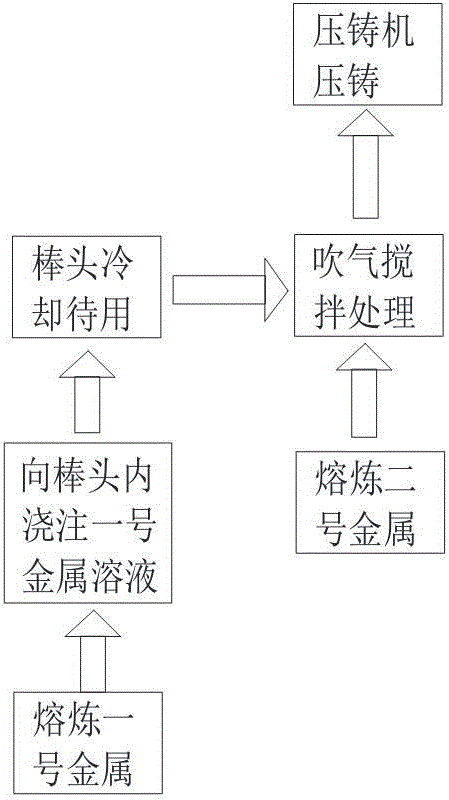

Method used

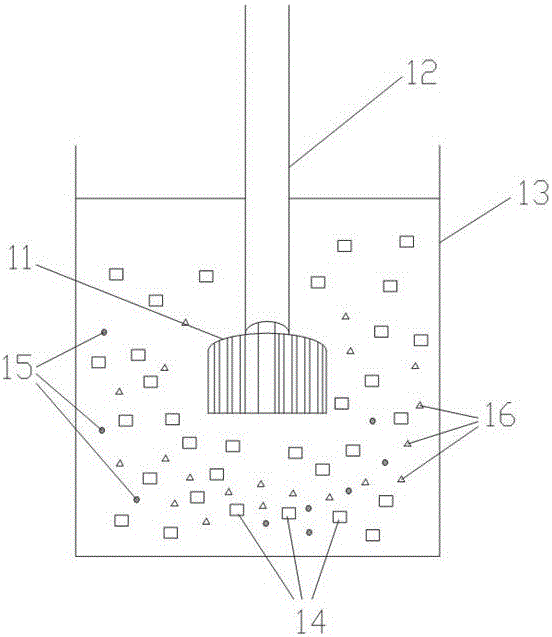

Image

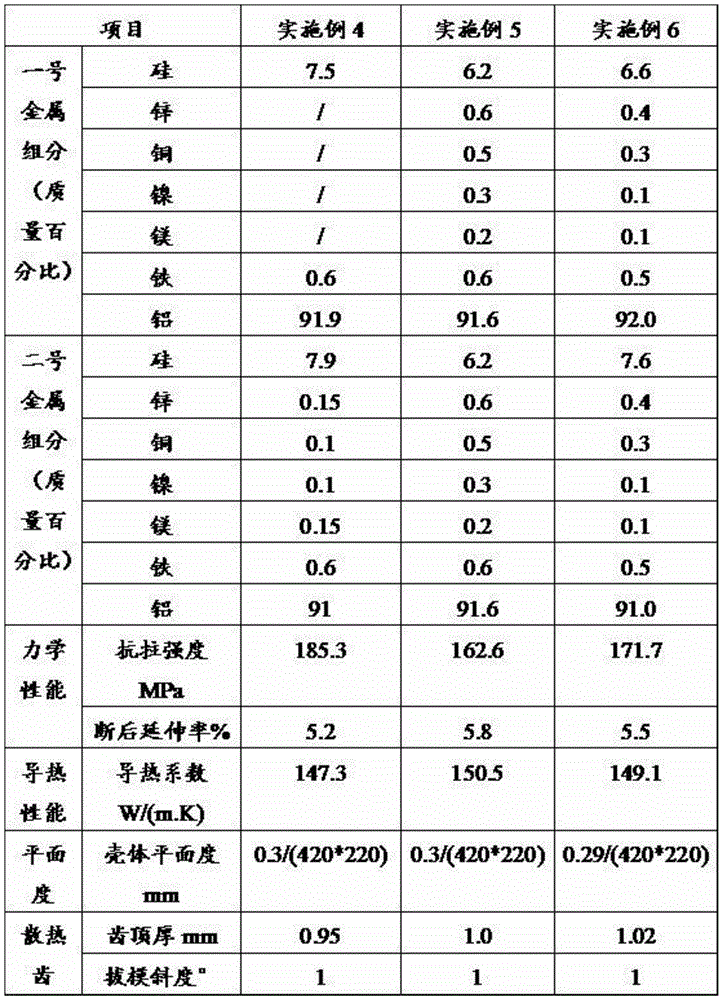

Examples

Embodiment 1

[0028] The technical solution adopted in the present invention is an aluminum-silicon alloy of rheological die-casting heat dissipation housing, the mass percentage of each component in the aluminum-silicon alloy is: silicon 8.0%, copper 1.5%, zinc 2.0%, nickel 2.0%, magnesium 0.8% , iron 1.0%, the rest is aluminum and unavoidable trace impurities.

Embodiment 2

[0030] An aluminum-silicon alloy for a rheological die-casting heat dissipation shell, the mass percentage of each component in the aluminum-silicon alloy is: 5.5% silicon, 0.1% copper, 0.1% zinc, 0.1% nickel, 0.1% magnesium, 0.1% iron, and the rest Aluminum and unavoidable trace impurities.

Embodiment 3

[0032] An aluminum-silicon alloy of a rheological die-casting heat dissipation shell, the mass percentage of each component in the aluminum-silicon alloy is: 6.5% silicon, 0.8% copper, 0.9% zinc, 0.8% nickel, 0.4% magnesium, 0.5% iron, and the rest Aluminum and unavoidable trace impurities.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com