Door lock inserting prevention structure

An anti-insertion and door lock technology, which is applied in building locks, building structures, buildings, etc., can solve the problems of unreliable anti-insertion effect and complex structure, and achieve the effect of simple structure and reasonable design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

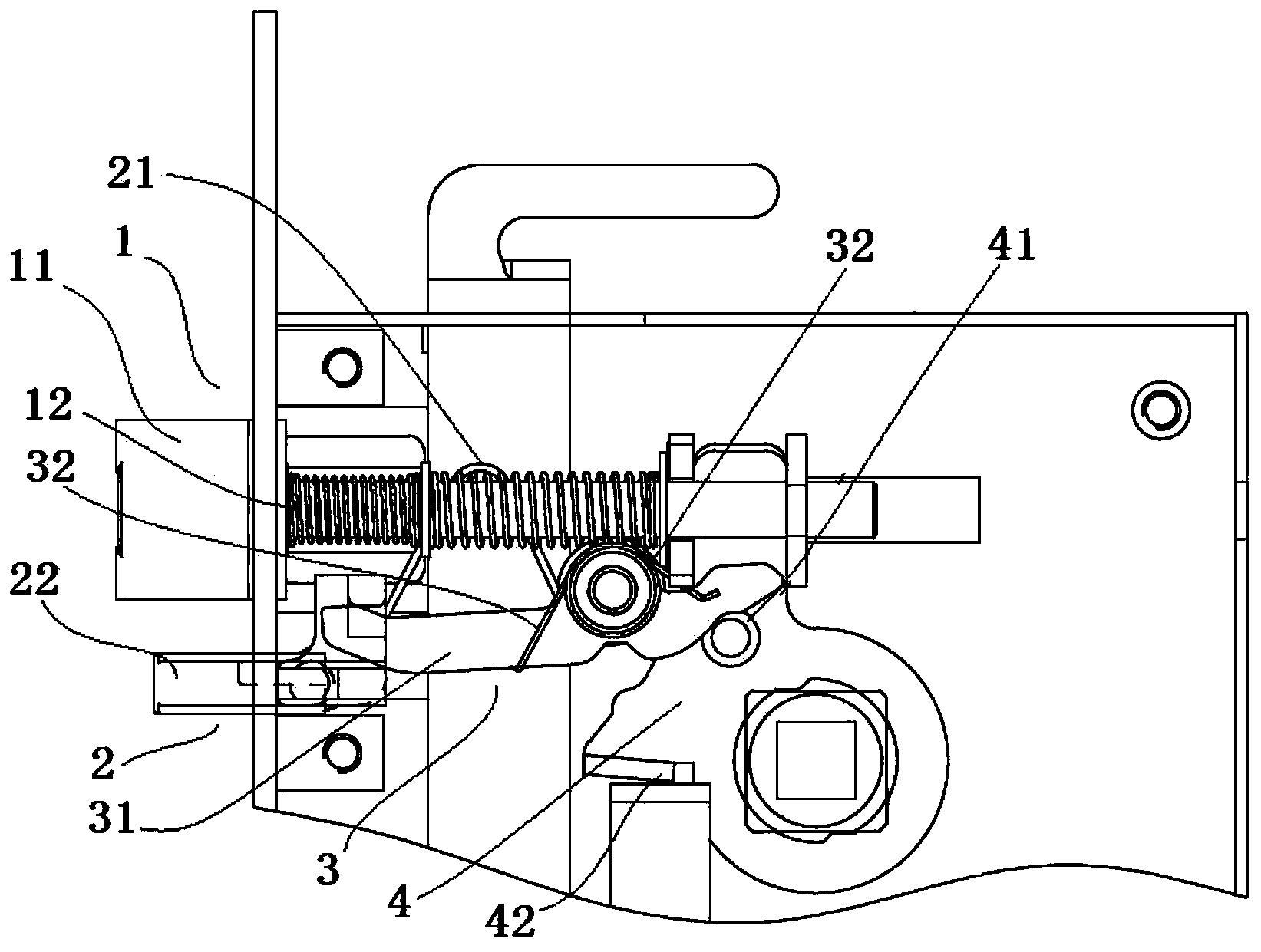

[0043] see Figure 1 to Figure 5 , an anti-insertion structure for a door lock, comprising: a bolt assembly 1 installed in a lock housing, the bolt assembly 1 includes a bolt 11 and a first deflector that makes the bolt 11 move toward the locking direction. Pressing piece 12, the latch bolt 11 can perform the reciprocating movement of locking out and retracting. The latch bolt 11 has an inclined surface facing the door panel. When the door is closed, the latch bolt 11 returns to the lock housing under the extrusion of the door panel. At this time, the latch tongue 11 is also subjected to the first biasing force of the first biasing member 12 towards the lock-out direction. Lock out under the action of a biasing force.

[0044] It also includes an anti-insertion tongue assembly 2, which is installed in the lock housing, see figure 1 , Figure 8 , which includes an anti-insertion tongue 22, and a second biasing member 21 that makes the anti-insertion tongue move toward the lo...

Embodiment 2

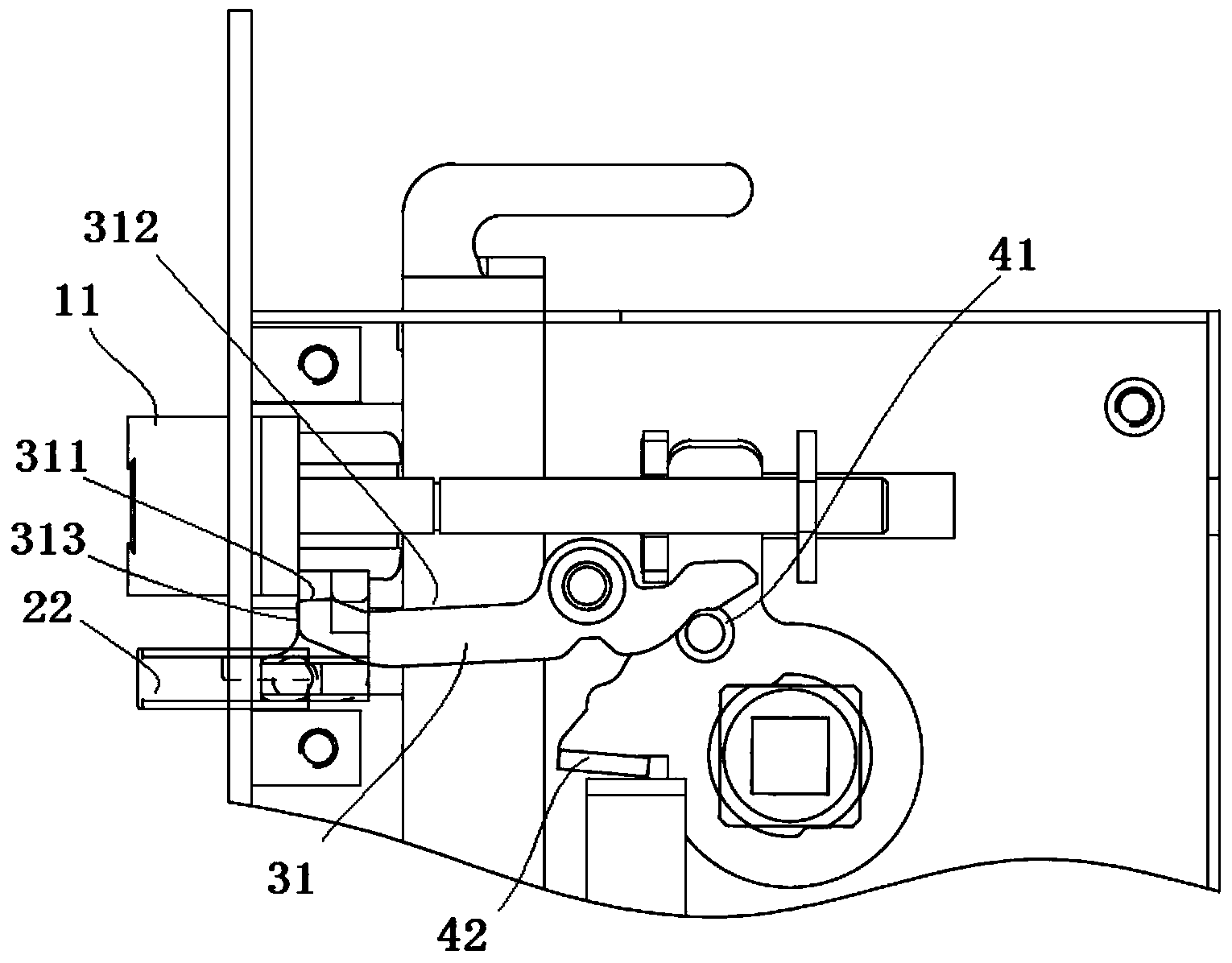

[0069] The difference between this embodiment and embodiment 1 is that, see Figure 9 , 10 , the anti-insertion swing bar 31 is in the shape of an "S", and the paddle assembly 4 also includes a second paddle 43 in the shape of a "6" that rotates together with the handle shaft or the lock cylinder. Next, the handle 431 of the second dial 43 is in contact with the end 313 of the anti-insertion lever 31, so that when the lock is unlocked, the rotation of the second dial 43 drives the anti-insertion lever 31 to release. Rotate against the opposing direction of the latch.

Embodiment 3

[0071] This embodiment is a deformation on the basis of embodiment 1 or embodiment 2, and the difference with embodiment 1 or 2 is:

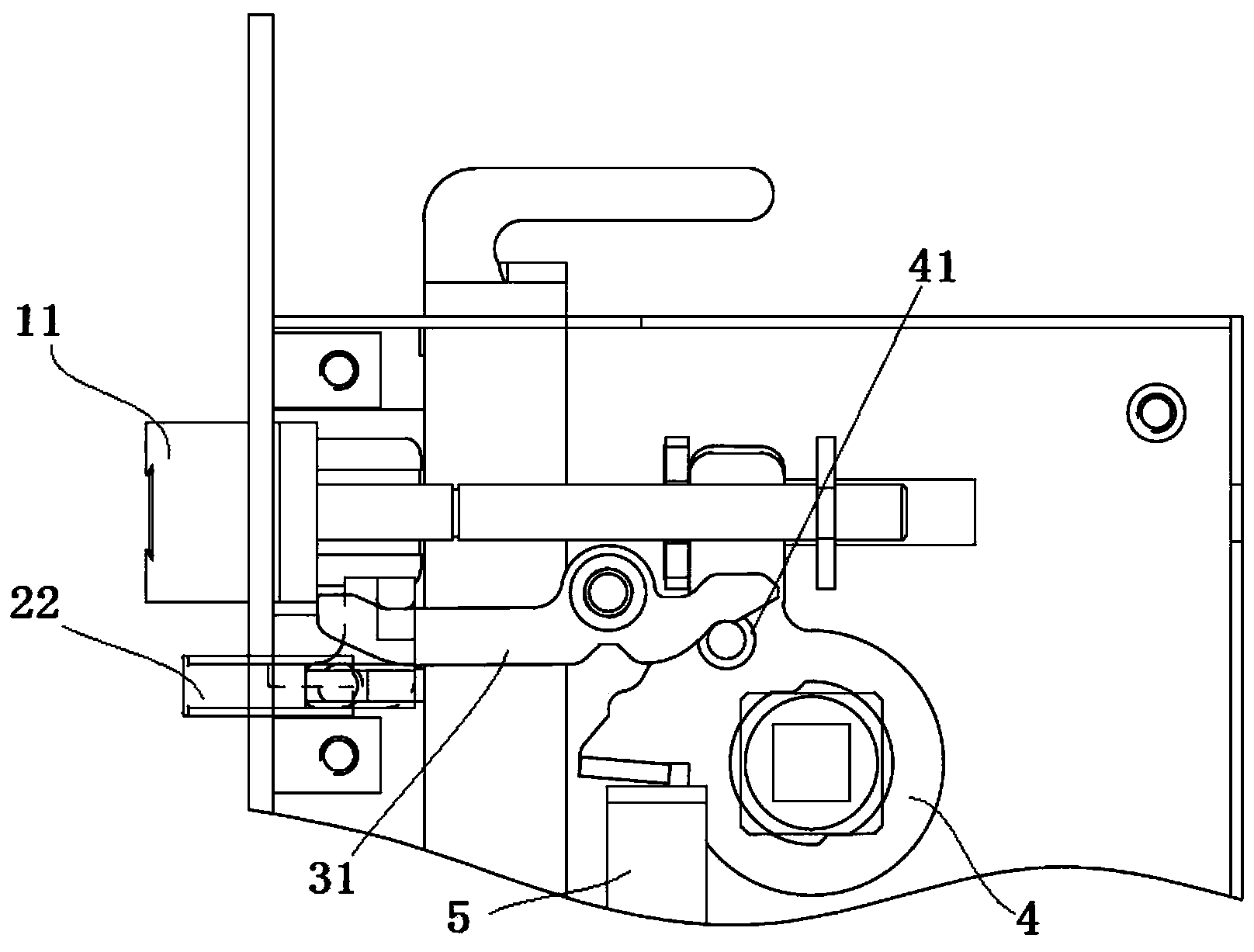

[0072] In this example, see Figure 1-5 , also includes when the key is used to unlock, the key drives the lock cylinder to rotate to drive its linear motion push rod 5, and the push rod 5 drives the paddle assembly 4 to rotate in the unlocking direction during the linear motion, thereby pushing the anti-lock The insertion swing lever 31 turns from the position against the oblique tongue 11 to the anti-insertion tongue position, and the unlocking pin 41 on the first paddle pushes the rear end of the insertion prevention swing lever 31 during the rotation process so that the insertion prevention swing lever 31 Rotate toward the direction of the anti-insertion tongue 22, so that the anti-insertion swing bar 31 is disengaged from the rear end surface of the oblique tongue 11, and the anti-insertion effect is released at this moment, and the door ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com