Well control pressure monitoring device and method

A technology of pressure, temperature and pressure, which is applied in the field of well control pressure monitoring and recording devices, can solve the problems of inaccurate basic data of pressure test in case of equipment operation, inability to implement responsibility after the event, artificially change pressure test data, etc., so as to ensure authenticity and The effect of timeliness, integrity assurance and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

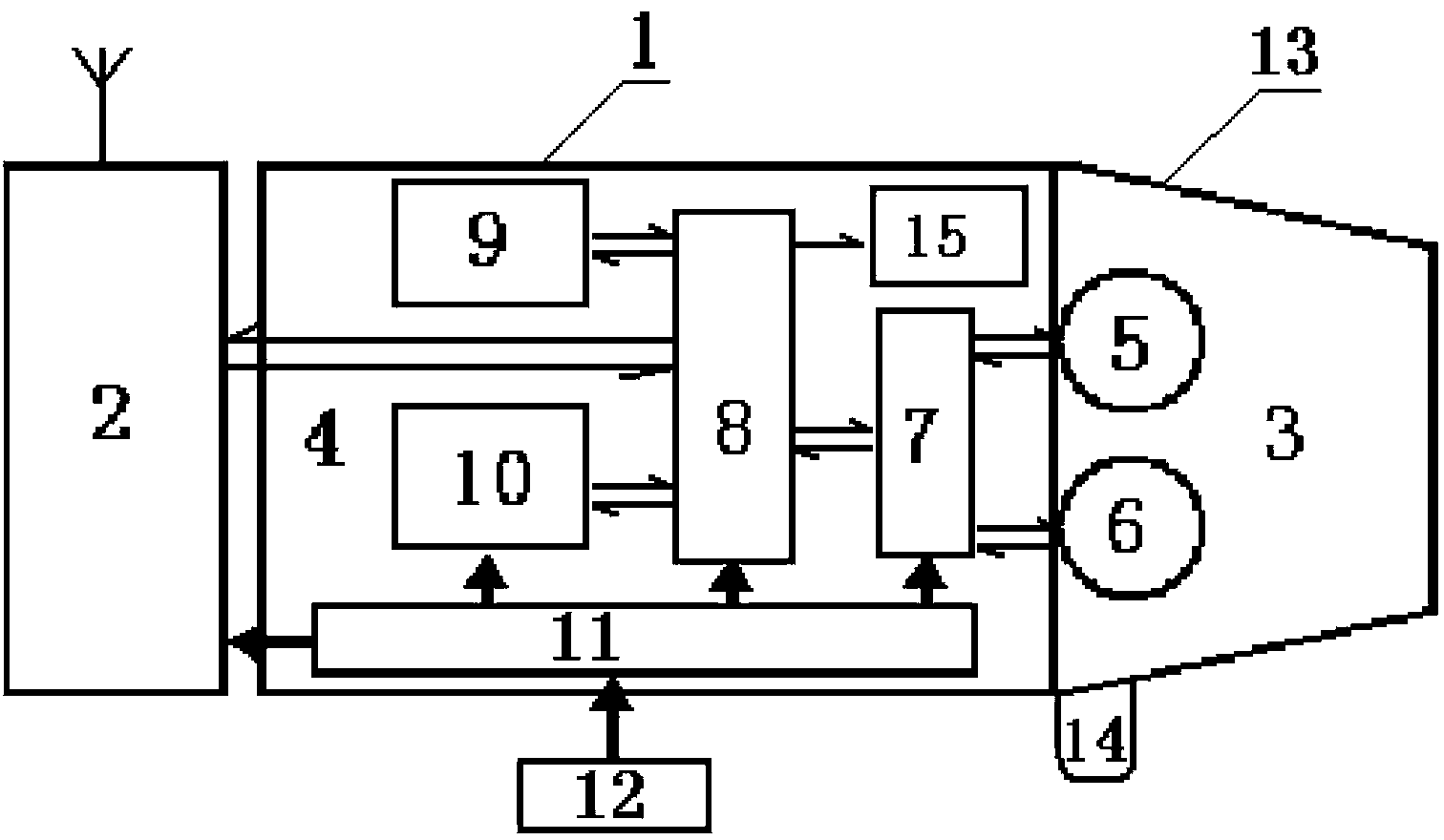

[0037] Embodiment 1: as figure 1 As shown, a well control pressure monitoring and recording device mainly includes an explosion-proof casing 1, a data remote transmission unit 2, a hyperbaric cabin 3, an electronic cabin 4, a pressure sensor 5, a temperature sensor 6, a temperature and pressure acquisition module 7, and a microprocessor 8 , storage module 9, touch screen display device 10, built-in reversible battery 11, power adapter 12, tubing thread 13, quick pressure relief unit 14, control unit 15;

[0038] The explosion-proof enclosure 1 is divided into a hyperbaric cabin 3 and an electronic cabin 4. A pressure sensor 5 and a temperature sensor 6 are installed in the hyperbaric cabin 3. A quick pressure relief unit 14 is placed beside the hyperbaric cabin 3. The quick pressure relief unit 14 is connected to the test chamber with a high-pressure hose. The inlet liquid storage tank of the pressure pump; the electronic cabin 4 is an explosion-proof atmospheric pressure cabi...

Embodiment 2

[0041] Embodiment 2: as figure 1As shown, a well control pressure monitoring and recording device mainly includes an explosion-proof casing 1, a pressure sensor 5, a temperature sensor 6, a temperature and pressure acquisition module 7, a microprocessor 8 and control software, a storage module 9, a data remote transmission unit 2, Touch screen display system 10, built-in reversible battery 11, power adapter 12, quick pressure relief unit 14 and control unit 15; pressure sensor 5 and temperature sensor 6 are installed in the hyperbaric chamber 3 with a maximum working pressure of 100 MPa at the front end of explosion-proof enclosure 1, and The outer circle of the hyperbaric chamber 3 is connected to the oil pipe thread 13 that is compatible with the equipment under test and the quick pressure relief unit 14 is placed beside it; Provide exclusive data to the microprocessor 8, use the control software to intelligently control the pressure test process, display the coordinate curv...

Embodiment 3

[0045] Embodiment 3: as figure 1 Shown, a kind of well control pressure monitoring and recording method comprises the following steps;

[0046] It mainly includes explosion-proof shell 1, pressure sensor 5, temperature sensor 6, temperature and pressure acquisition module 7, microprocessor 8, storage module 9, data remote transmission unit 2, touch screen display system 10, built-in reversible battery 11, power adapter 12, fast The pressure relief unit 14, the control unit 15, etc.; the pressure sensor 5 and the temperature sensor 6 are installed in the hyperbaric chamber 3 with a maximum working pressure of 100 MPa at the front end of the explosion-proof enclosure 1, and the outer circle of the hyperbaric chamber 3 is used to match the oil pipe of the equipment under test The screw thread 13 is connected with the device under test, and a quick pressure relief unit 14 is set aside. The electronic cabin 4 at the rear end of the explosion-proof enclosure 1 integrates a temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com