Electromagnetic four-way reversing valve

A four-way reversing valve and electromagnetic technology, applied in the field of electromagnetic valve, can solve the problem of high manufacturing cost and achieve the effect of reducing manufacturing cost and volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

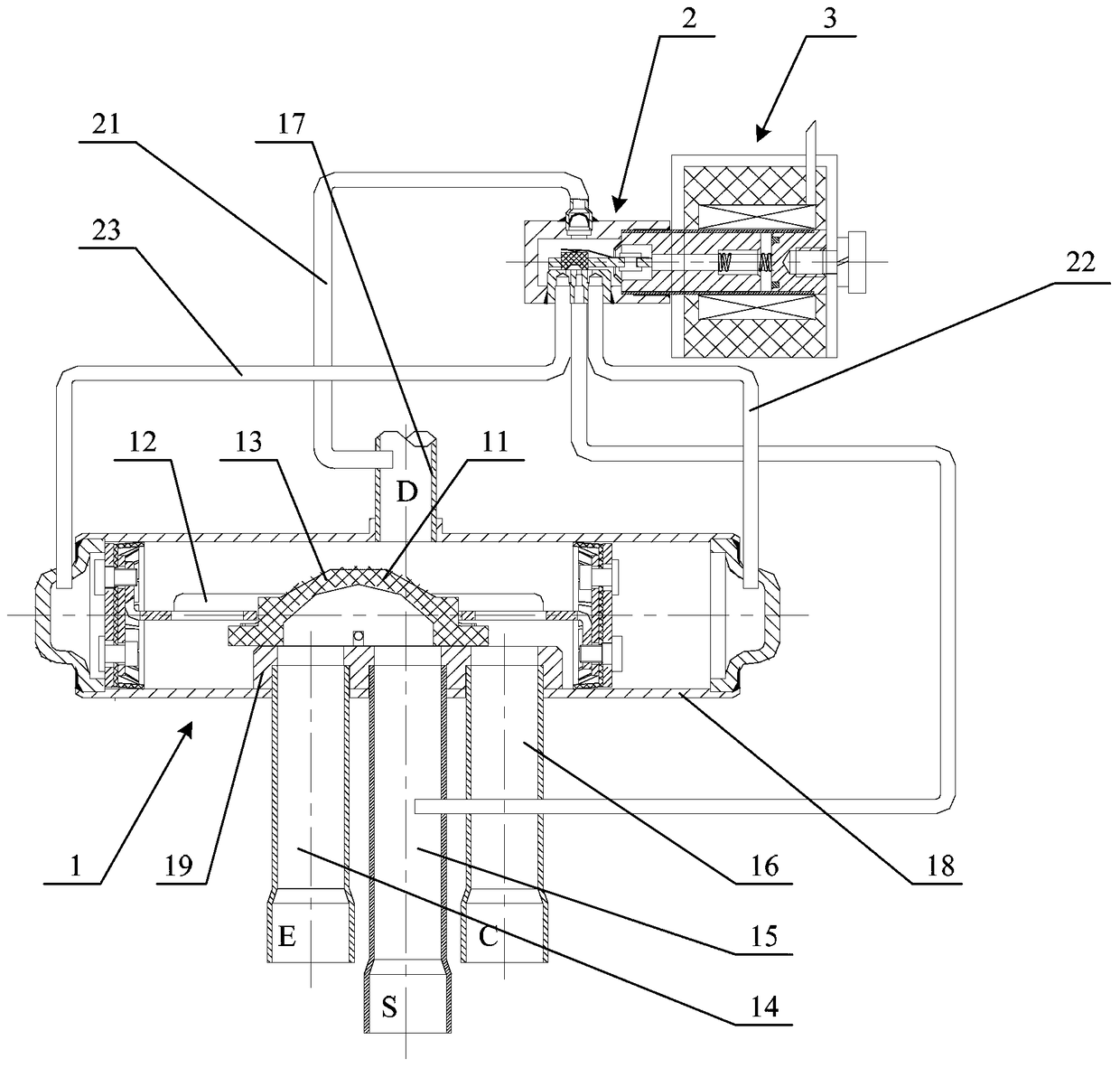

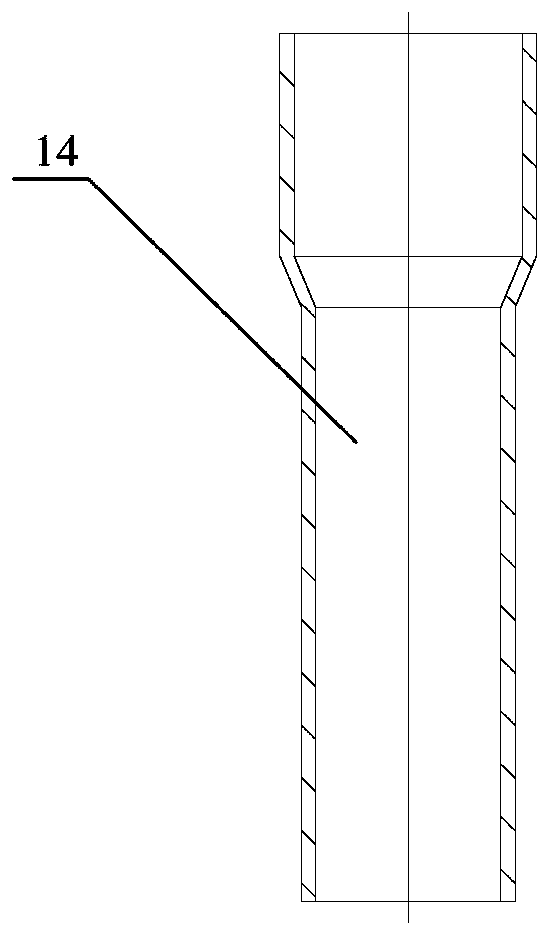

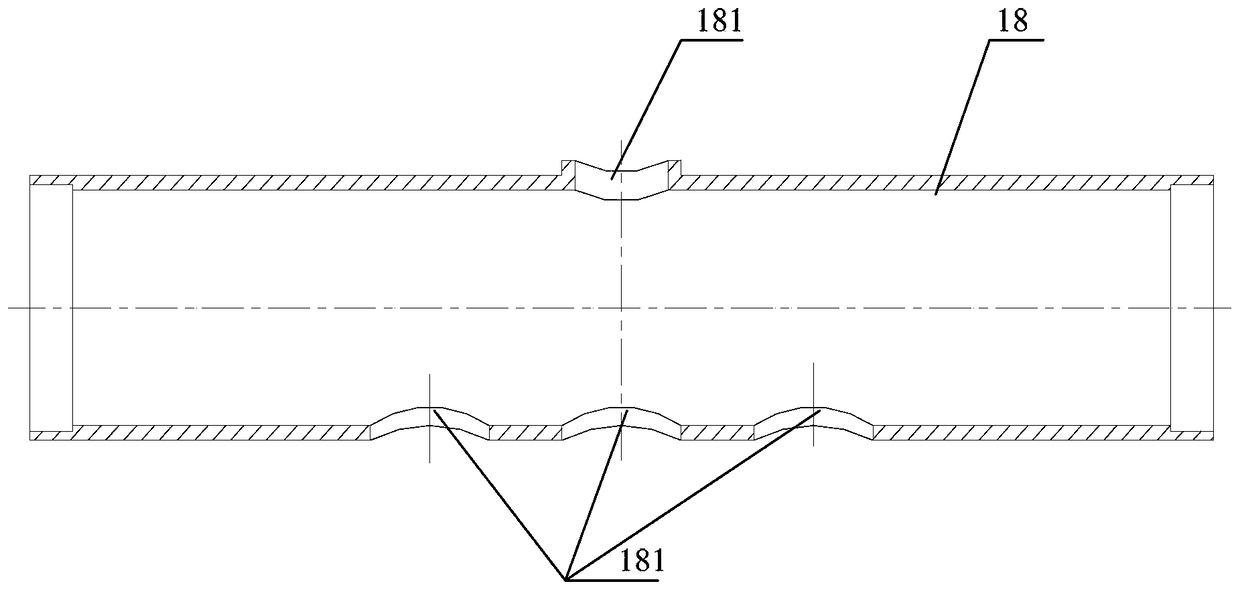

[0029] Figure 5A A structural schematic diagram of the E-connector in the electromagnetic four-way reversing valve provided by the first embodiment of the present invention; Figure 5B for Figure 5A The top view of the E-connector shown; Figure 6A The front view of the main valve body in the electromagnetic four-way reversing valve provided by the first embodiment of the present invention; Figure 6B for Figure 6A Bottom view of main valve body shown; Figure 7A The front view of the main valve seat in the electromagnetic four-way reversing valve provided by the first embodiment of the present invention; Figure 7B for Figure 7A Top view of main valve seat shown.

[0030] see Figure 5A-Figure 7B , combined with figure 1 , the electromagnetic four-way reversing valve provided in this embodiment includes a main valve 1, a pilot valve 2 and an electromagnetic coil 3; the main valve 1 includes a main valve body 18, a main valve seat 19, two pistons 11, a guide frame ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com