Vertical type evaporator

An evaporator and vertical technology, which is applied in the field of new high-efficiency vertical evaporators, can solve the problems of reducing heat exchange efficiency, achieve high heat exchange efficiency, reduce gas pressure drop, and save equipment footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

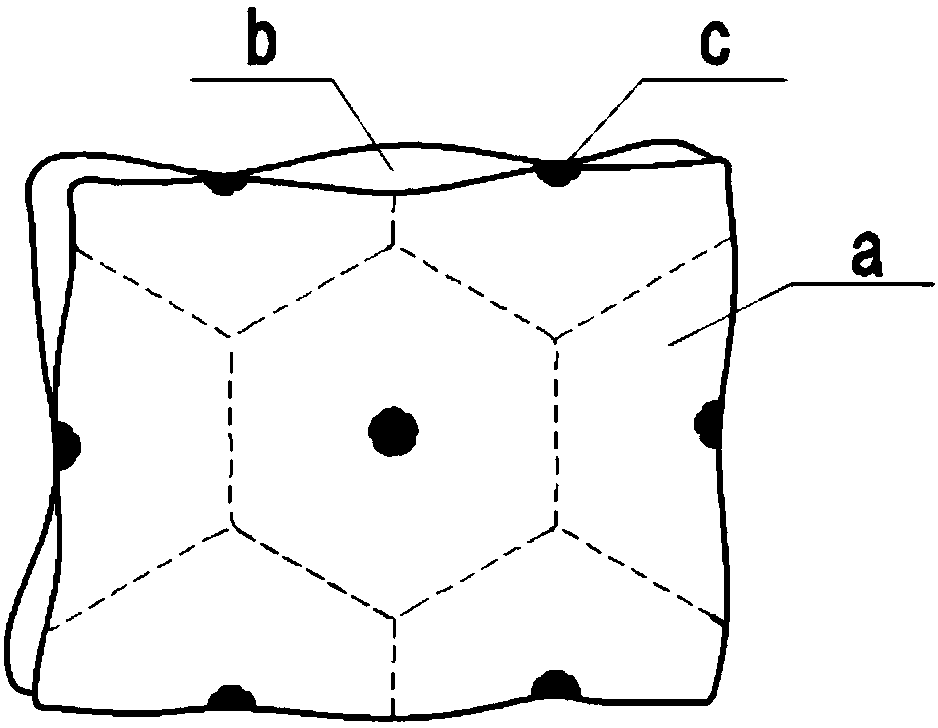

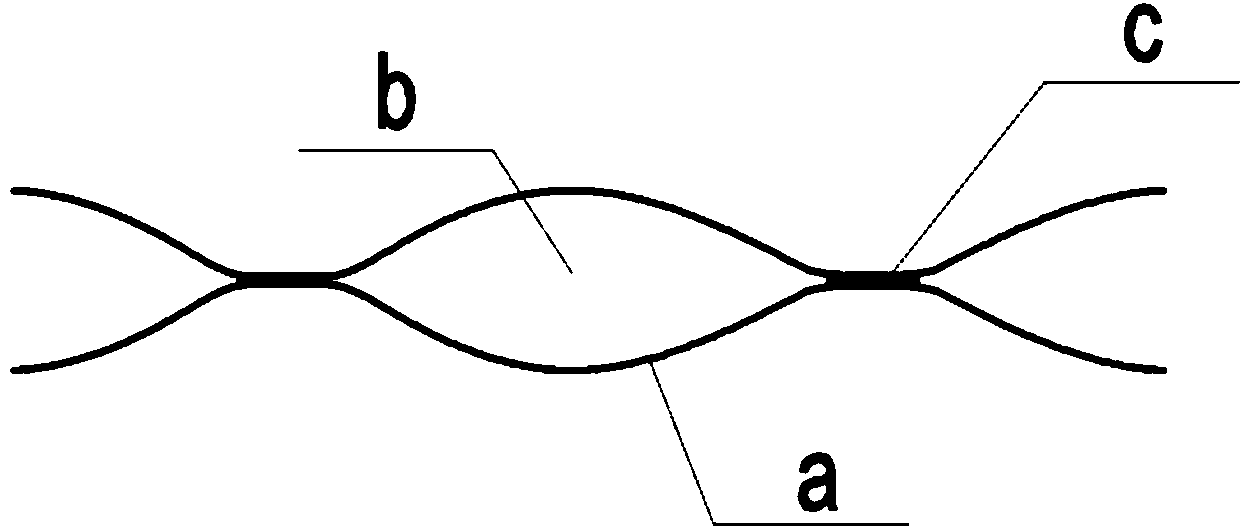

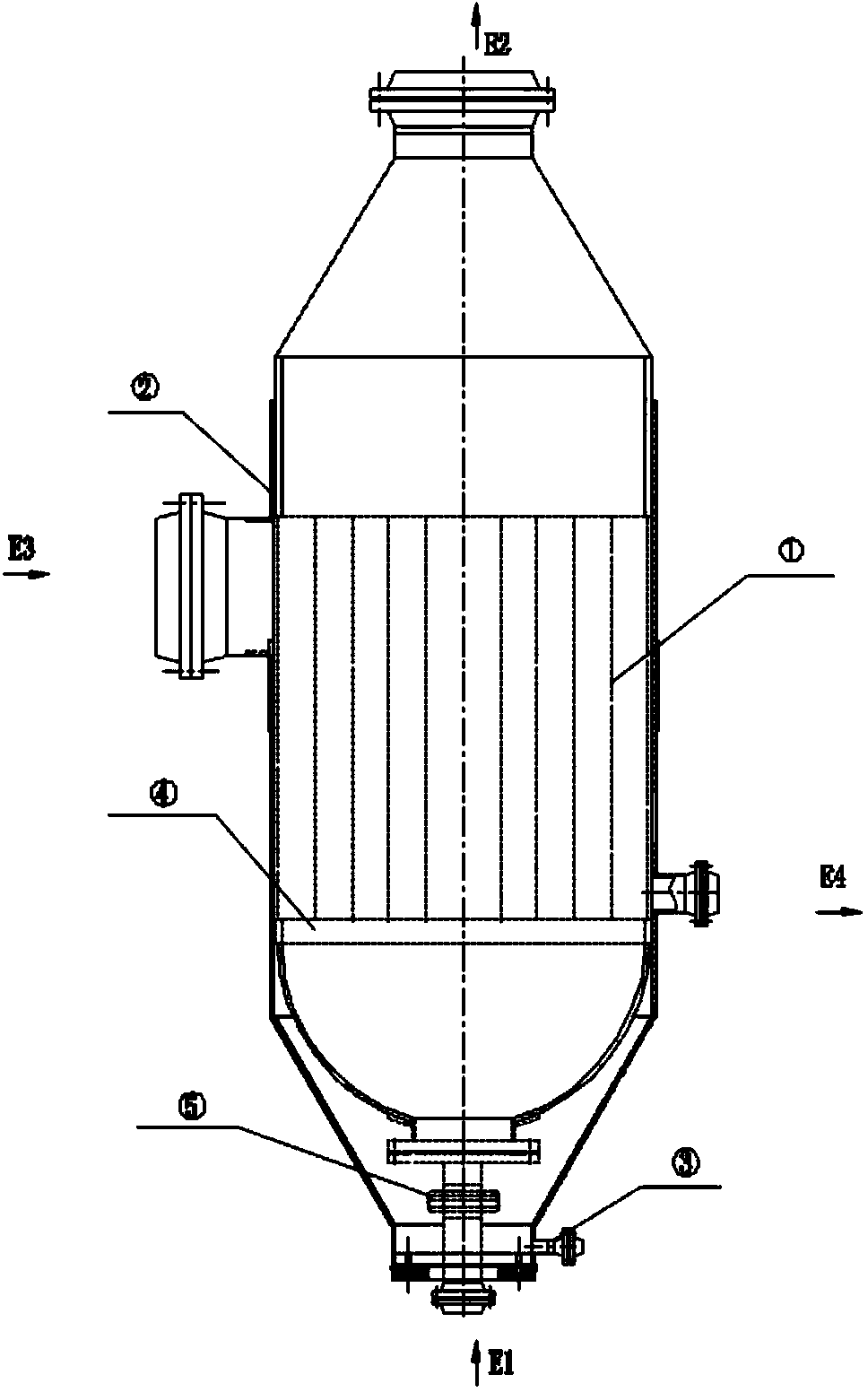

[0040] Such as Figure 1~3 As shown, a vertical evaporator, the evaporator includes a heat exchange element, an expansion joint ⑤ and a shell ②, the heat exchange element in the evaporator is a pillow heat transfer element, and the pillow heat transfer element consists of multiple pairs The plate pair bundle composed of heat exchange plate pairs ①, and the fixture ④ that controls the distance between each heat exchange plate pair. The joint is usually set at the lower end of the heat exchange plate bundle. It is an elastic compensation element that can freely expand and contract, and can effectively compensate for axial deformation. When the bundle of heat exchange plates and the shell are deformed inconsistently due to temperature difference and pressure, it can absorb the deformation energy and automatically adjust the stress in the bundle of shells and heat exchange plates. The heat exchange plate pair is composed of two metal plates through multi-point welding to form a p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com