Measuring platform and measuring method for measuring surface roughness of thin steel plate

A technology of surface roughness and thin steel plate, which is applied in the direction of mechanical roughness/irregularity measurement, etc., can solve the problem that the surface roughness of thin steel plate cannot be accurately measured, and achieve the effect of simple structure, low manufacturing cost and convenient portability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

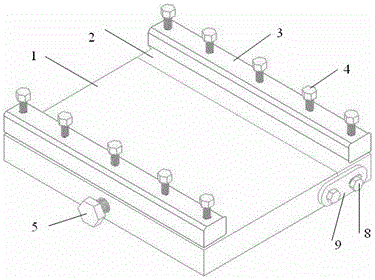

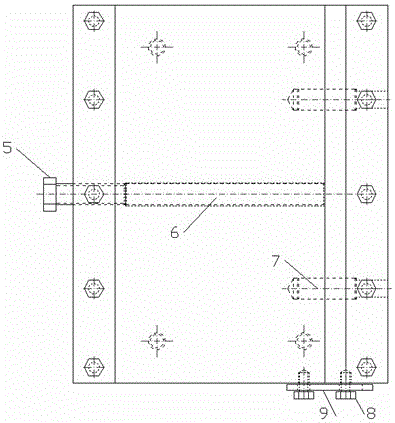

Embodiment 1

[0032] Embodiment 1: Clean the surface of the thin steel plate to be tested with a thickness of 0.3mm, length 150mm, and width 100mm, and put it flat on the assembled measuring platform after being dried, insert one end of the rolling line of the thin steel plate to be tested into the main Tighten the fixed bolt 4 in the gap between the platform 1 and the movable platen 3, the movable platen 3 will press the thin steel plate to be tested on the end of the working surface of the main platform 1, and spread the thin steel plate to be tested on the working surface of the main platform 1. Insert the other end of the thin steel plate into the gap between the auxiliary platform 2 and the movable platen 3, tighten the fixing bolt 4, the movable platen 3 presses the thin steel plate to be tested on the end of the working surface of the auxiliary platform 2, and rotate the tension bolt 5, the tension bolt 5 Push the pressure rod 6 to exert pressure on the auxiliary platform 2, and the a...

Embodiment 2

[0033] Embodiment 2: Clean the surface of an uneven rolled hard stainless steel sheet with a thickness of 0.2mm, a length of 180mm, and a width of 150mm, and put it flat on the assembled measuring platform after being blown dry, and insert one end of the rolling flow line of the thin steel sheet to be tested into the main Tighten the fixed bolt 4 in the gap between the platform 1 and the movable platen 3, the movable platen 3 will press the thin steel plate to be tested on the end of the working surface of the main platform 1, and spread the thin steel plate to be tested on the working surface of the main platform 1. Insert the other end of the thin steel plate into the gap between the auxiliary platform 2 and the movable platen 3, tighten the fixing bolt 4, the movable platen 3 presses the thin steel plate to be tested on the end of the working surface of the auxiliary platform 2, and rotate the tension bolt 5, the tension bolt 5 Push the pressure rod 6 to exert pressure on th...

Embodiment 3

[0034]Example 3: Clean the surface of a metal foil with a thickness of 0.1mm, a length of 200mm, and a width of 160mm, and then place it flat on the assembled measuring platform after drying, and insert one end of the rolling line of the metal foil to be tested into the main platform 1 Tighten the fixing bolt 4, the movable pressure plate 3 will press the metal foil material to be tested on the end of the working surface of the main platform 1, and spread the metal foil material to be tested on the working surface of the main platform 1. The other end of the metal foil to be tested is inserted into the gap between the auxiliary platform 2 and the movable pressure plate 3, tighten the fixing bolt 4, the movable pressure plate 3 presses the metal foil to be tested on the end of the working surface of the auxiliary platform 2, rotate the tension bolt 5, The bolt 5 pushes the pressure rod 6 to exert pressure on the auxiliary platform 2, and the auxiliary platform 2 pulls the metal ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com