Self-calibration method for grid point system error of two-dimensional grid plate

A system error and grid plate technology, applied in the field of grid point system error self-calibration, can solve the problem of not considering the coordinate origin deviation, etc., and achieve the effect of low calibration error and high calculation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

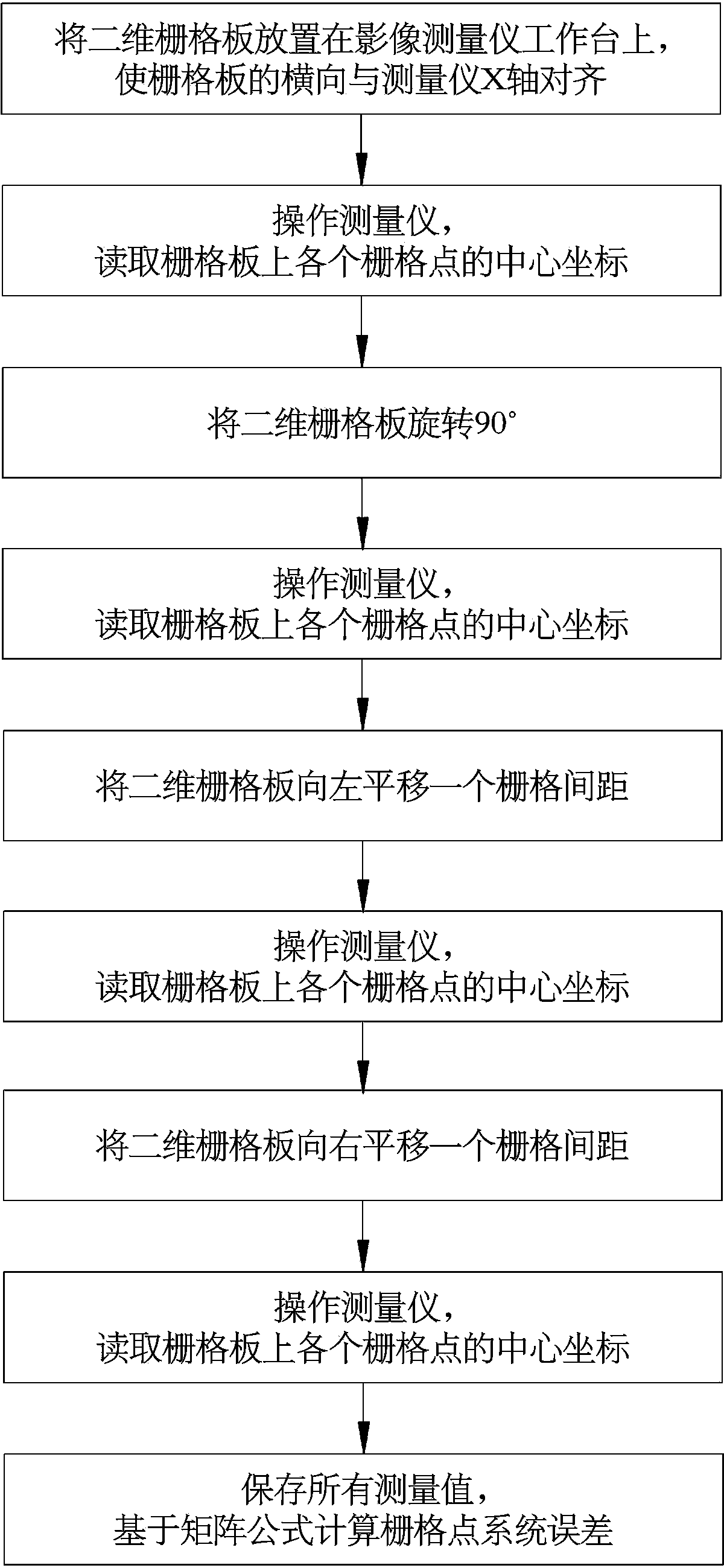

[0027] The technical solution of the present invention will be described in further detail below with reference to the accompanying drawings and specific implementation steps.

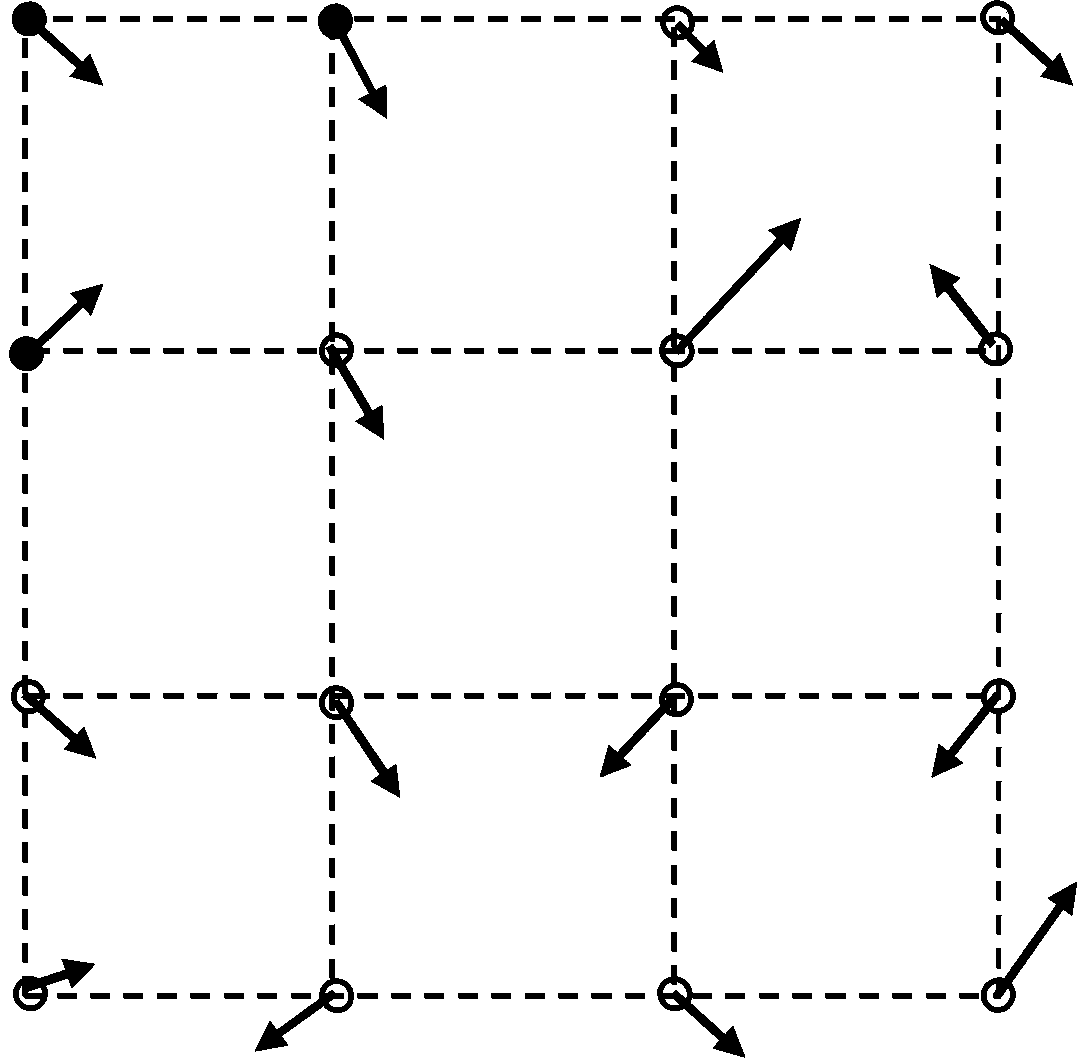

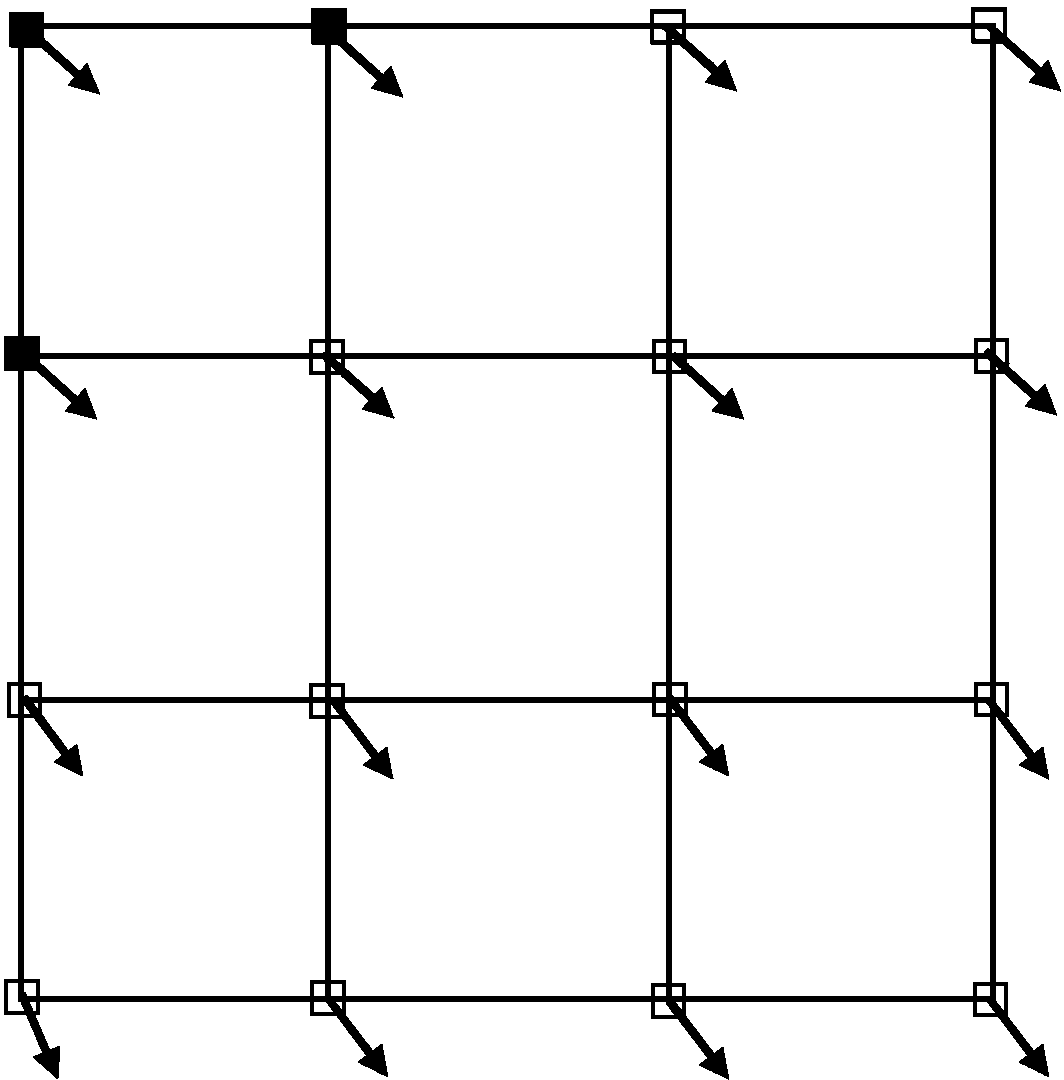

[0028] According to attached figure 1 ~ attached Figure 4 , a grid point system error self-calibration method of a two-dimensional grid plate of the present invention, comprising the following steps:

[0029] 1) Place the two-dimensional grid plate to be calibrated on the workbench of the image measuring instrument through the carrying fixture. The systematic error of each grid point on the two-dimensional grid plate is denoted as S n , and the systematic error of the image measuring instrument workbench corresponding to each grid point is recorded as A n , where n=[1,N], N is the number of grid points.

[0030] 2) At the initial position 0, use the image measuring instrument to sequentially read the center coordinates of each grid point, and record the reading as M 0,n , this measurement is dete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com