Sensing device based on friction generating technology and preparing and using method of sensing device

A technology of sensing device and friction power generation, which is applied in the direction of friction generator and electric/magnetic device to transmit sensing components, etc., can solve the problems of complex positioning circuit, unfavorable application, low resolution, etc., and achieve simple output signal wiring, The effect of simple manufacturing process and high resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

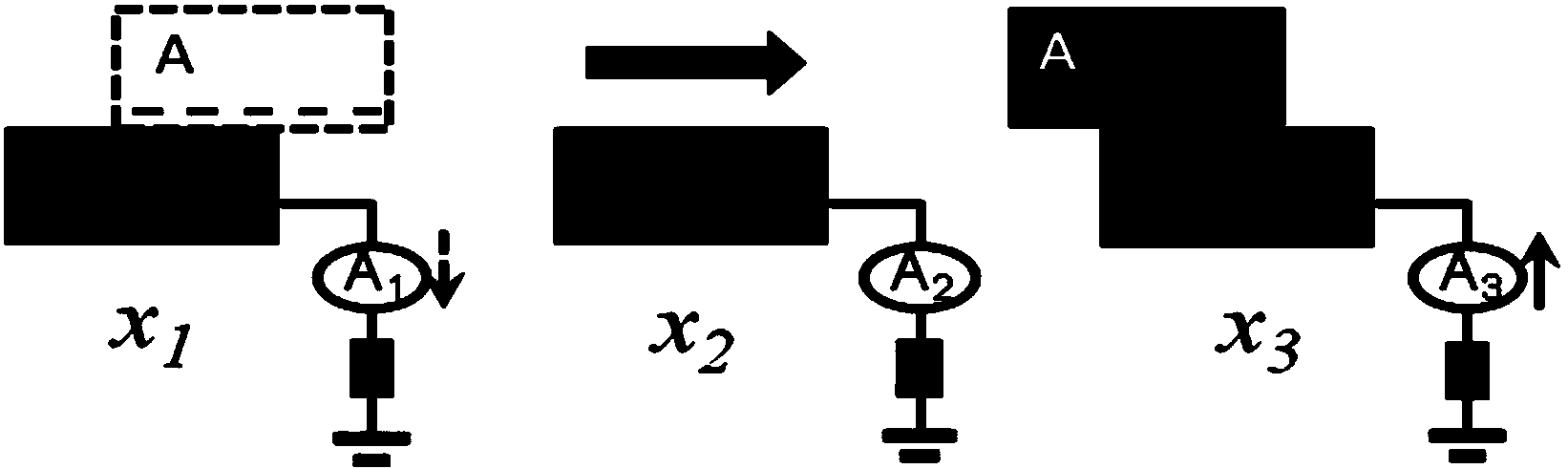

[0093] Another manufacturing method of the sensing device provided by the present invention is more suitable for the case where the first unit 10 and the second unit 20 have opposite upper and lower relative positions at any two adjacent intersection points. Specifically include the following steps:

[0094] (1) Provide n+m wires whose interior is a conductor and whose exterior is coated with insulating material, and several electrical signal output terminals with one end grounded;

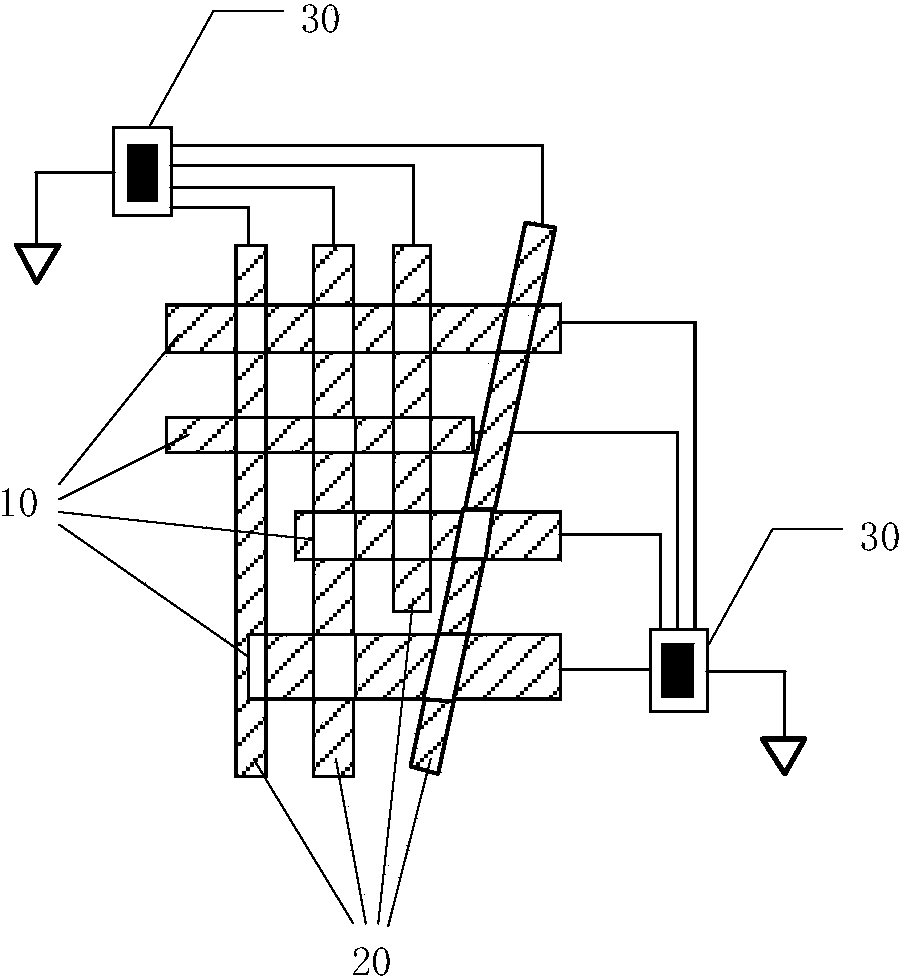

[0095] (2) Using n threads as warps and m threads as wefts, the warps and wefts intersect each other to form a network structure, each warp is a first unit, and each weft is a Second unit;

[0096] (3) The n warp threads and the m weft threads are respectively electrically connected to the electrical signal output terminal through internal conductors, so as to individually monitor the output signal of each unit.

[0097] Wherein the formation of the network structure in step (2) may adopt a conv...

Embodiment 1

[0117] Example 1 θ = arctg v y v x = arctg a y a x - - - ( 7 )

[0118] Prepare a perforated plexiglass with a size of 20cm×20cm as the substrate, spread 9 aluminum strips with a width of 6mm and a length of 20cm in parallel on the x-direction of the substrate surface, and the distance d between adjacent aluminum strips is 14mm, And the lower surface of each aluminum strip passes through 9 uniformly arranged holes on the base, and the part passing through the holes is embedded into the holes by extrusion. Prepare another 9 aluminum strips of the same size and spread them on the surface of the above-mentioned substrate along the y direction in a similar manner, ...

Embodiment 2

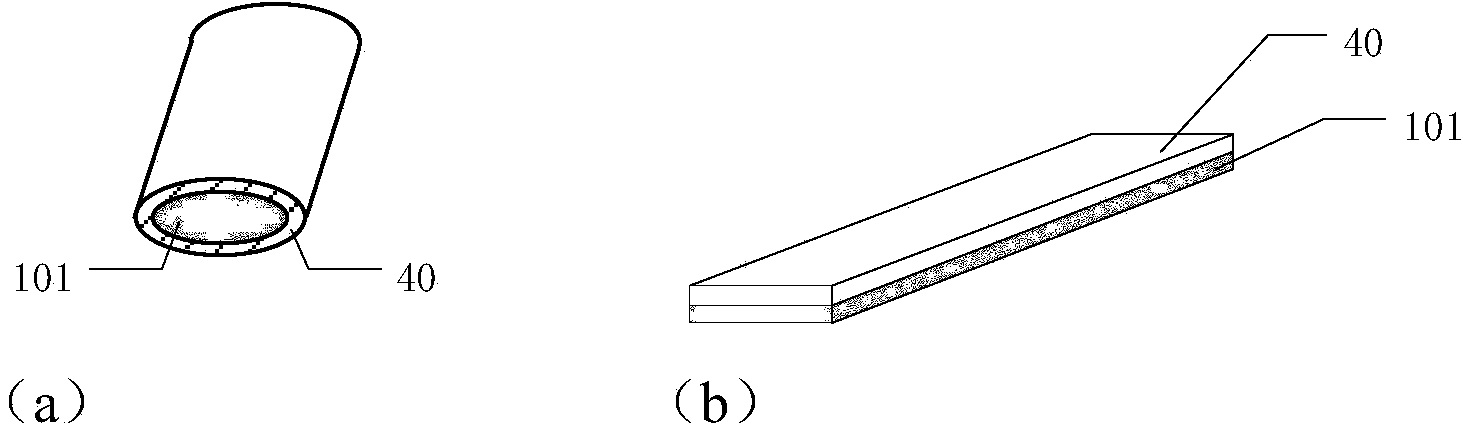

[0121] The enameled wire with a diameter of about 120 μm is woven into a mesh structure, the grid spacing is 250 μm, and the number of electrodes in the dimension is 41 on the length of 1 cm. 2 The area of has 41 x output terminals and 41 y output terminals, forming 41×41=1681 pixel resolution, such as Figure 11 (a) shown. When an object with a diameter of 1.2mm slides along the "G" track on the device, the single signal output of its x output and y output is as follows: Figure 11 As shown in (b), the current signal-to-noise ratio reaches 50. Such as Figure 11 (c) is the time-varying relationship of the x-y output current peak signal during the movement of the slider. Its motion trajectory can be clearly seen from the x-y coordinate axis, and its motion speed and acceleration can be calculated through the x-t and y-t relationships.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com