Ultralow power consumption magnetic induction type floater water level sensor and signal processing method

A water level sensor and magnetic induction technology, applied in buoy liquid level indicators and other directions, can solve the problems of inconvenient transportation and carrying of large-capacity batteries, and achieve the effect of enhancing battery life and reducing operating power consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

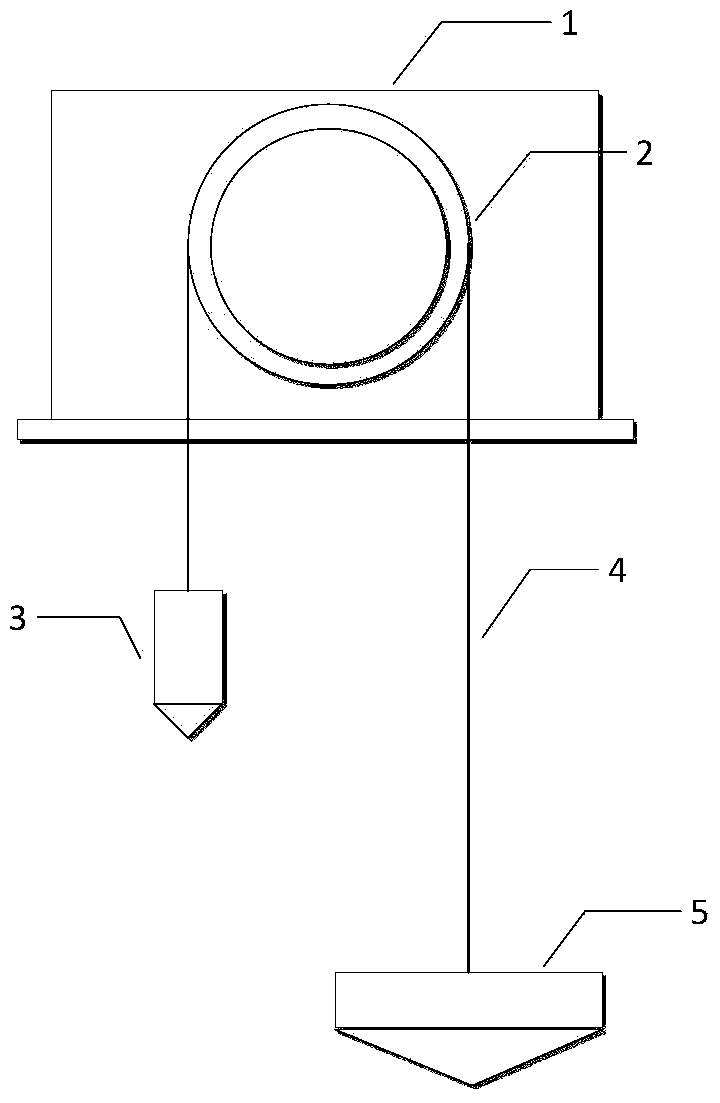

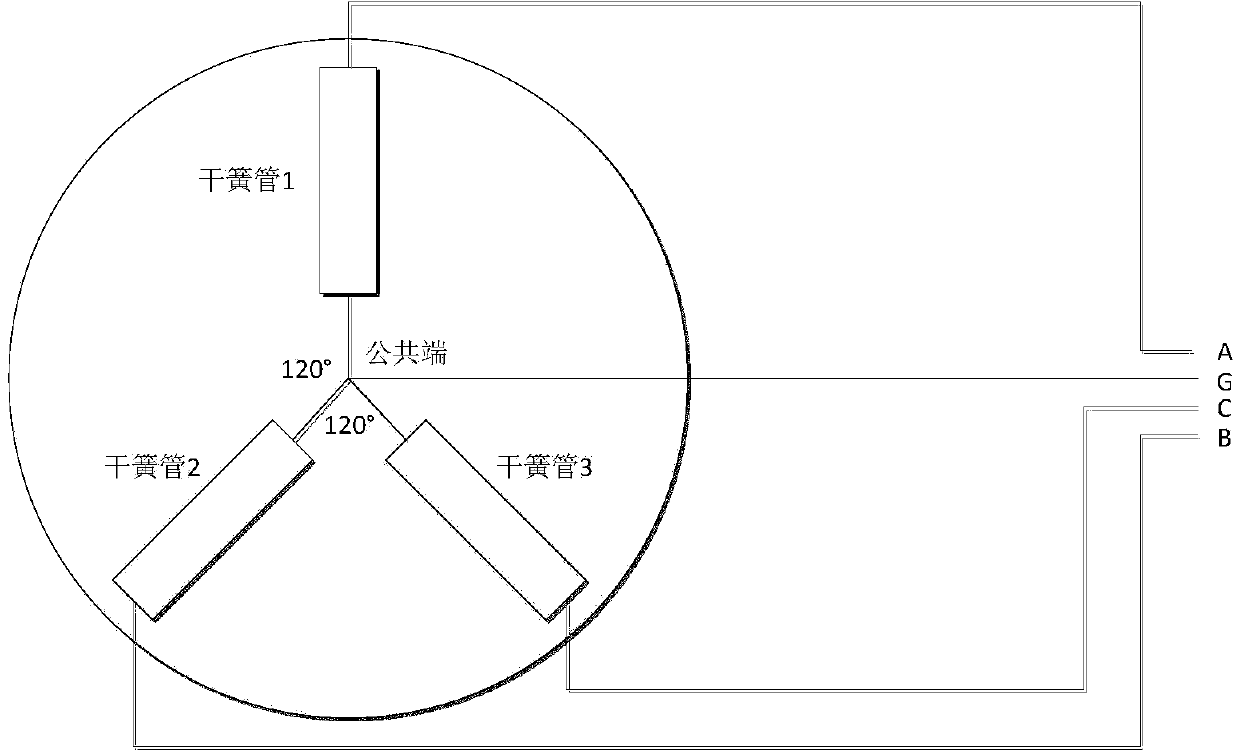

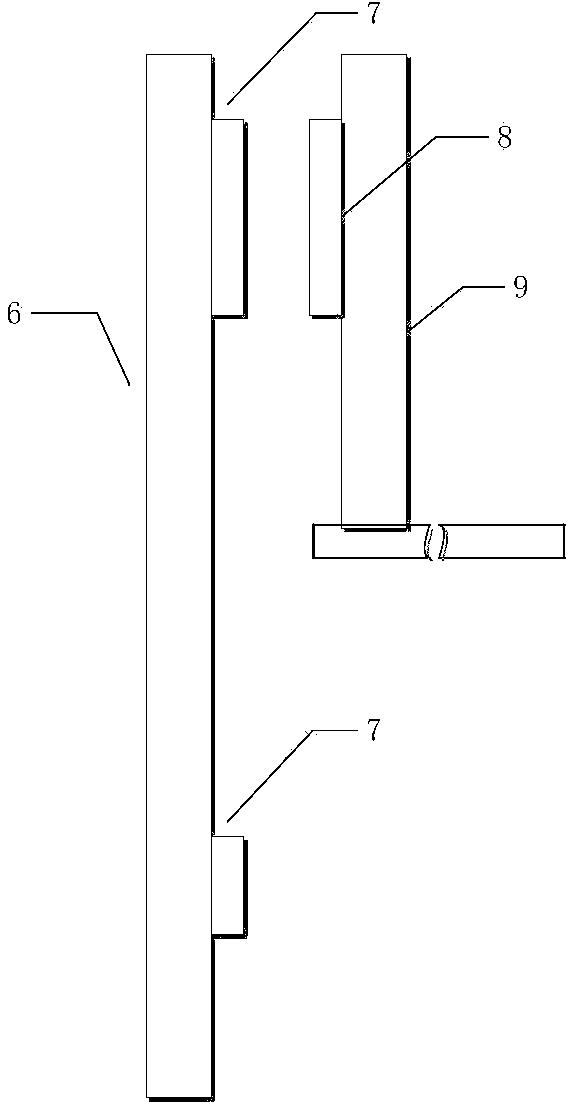

[0031] The ultra-low power consumption magnetic induction type float water level sensor of the present invention is as figure 1 As shown, it consists of an encoder, a transmission gear set, a water level gauge wheel 2, a counterweight 3, a steel wire rope 4 and a float 5, wherein the encoder and transmission gear set are installed on the shell 1 of the float water level sensor, and the steel wire rope 4 is installed on the water level sensor. On the meter wheel 2, one end of the wire rope 4 is a counterweight 3, and the other end is a float 5. The transmission gear set includes 2 sets of transmission gears and transmission shafts. The two transmission gears are meshed. One transmission shaft is coaxial with the rotating arm, and the other transmission shaft is coaxial with the water level gauge wheel. When the water level rises or falls, Steel wire rope 4 drives water level meter wheel 2 to rotate, and water level meter wheel 2 drives the transmission gear on the same transmis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com