Six-dimensional force transducer calibration device

A six-dimensional force sensor and calibration device technology, applied in the field of sensor calibration, can solve problems such as errors, affecting the accuracy of calibration devices, installation errors, etc., and achieve the effects of high precision, simple structure, and reduced calibration errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with accompanying drawing, the patent of the present invention is further described.

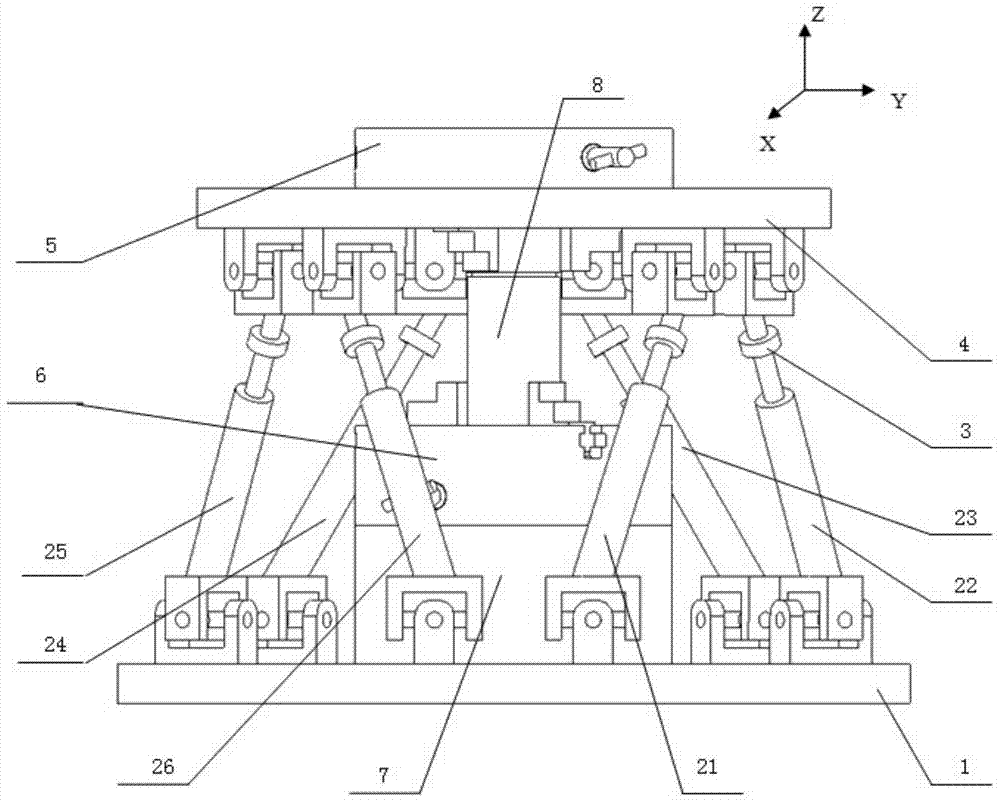

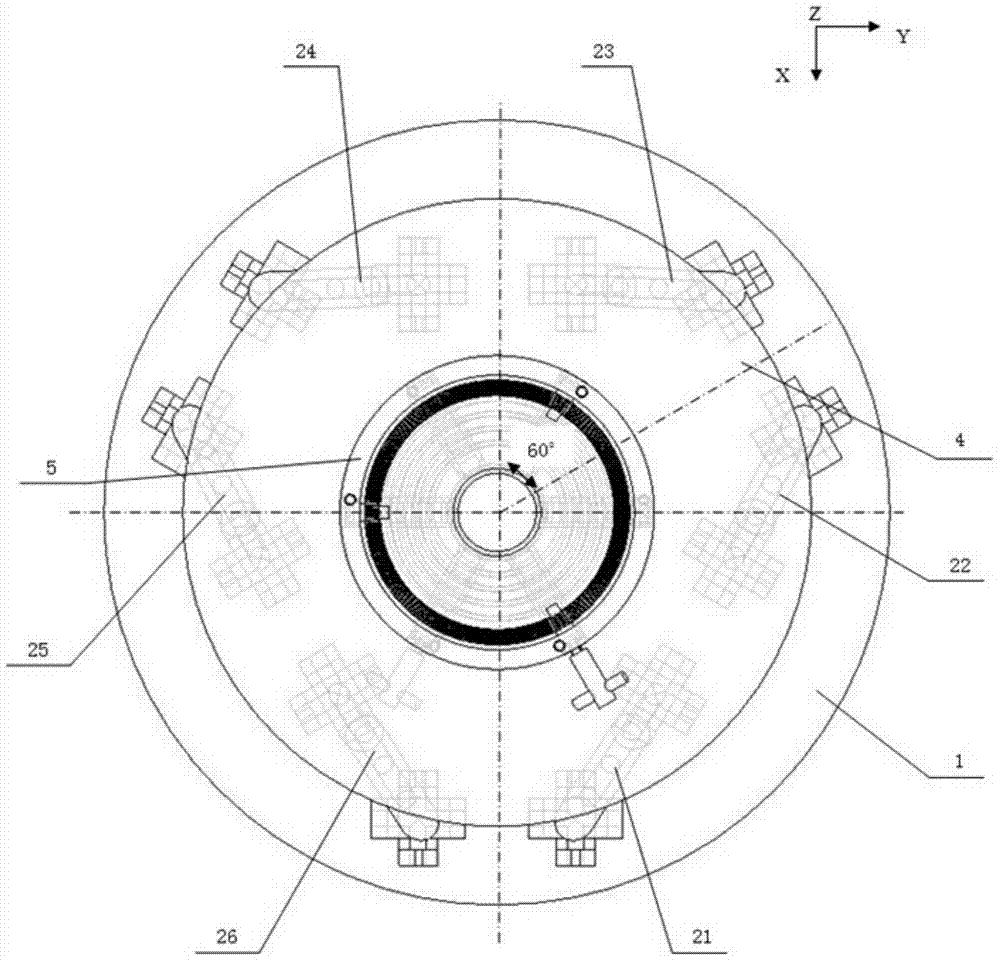

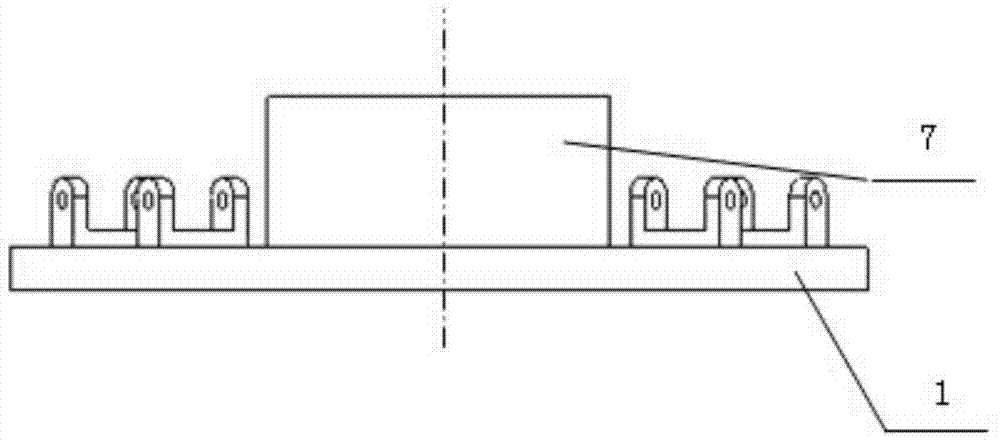

[0024] figure 1 and figure 2 Shown are respectively the three-dimensional structure schematic diagram and the top view of the present invention. The six universal hinges on the base 1 form a group of two with a certain distance and are evenly distributed with the other two groups on the base 1 at a distance of 120 degrees. The axis of the pin hole of the universal joint is along the normal direction of the base. The axis of the base 1 and the sensor fixing platform 7 coincide and are rigidly connected together. The six universal hinges on the calibration work platform 4 are divided into two groups with a certain distance and evenly distributed with the other two groups at a distance of 120 degrees. The axis of the pin hole of the universal joint is along the normal direction of the base. The three sets of universal hinges on the calibration work platform 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com