Vertical dropping impact test system

An impact test and tested technology, applied in the direction of impact test, vibration test, machine/structural component test, etc., can solve the problems of inaccurate test results, unfavorable use, single test function, etc., to prevent equipment damage and personal injury. Injury, cost savings, accurate test results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

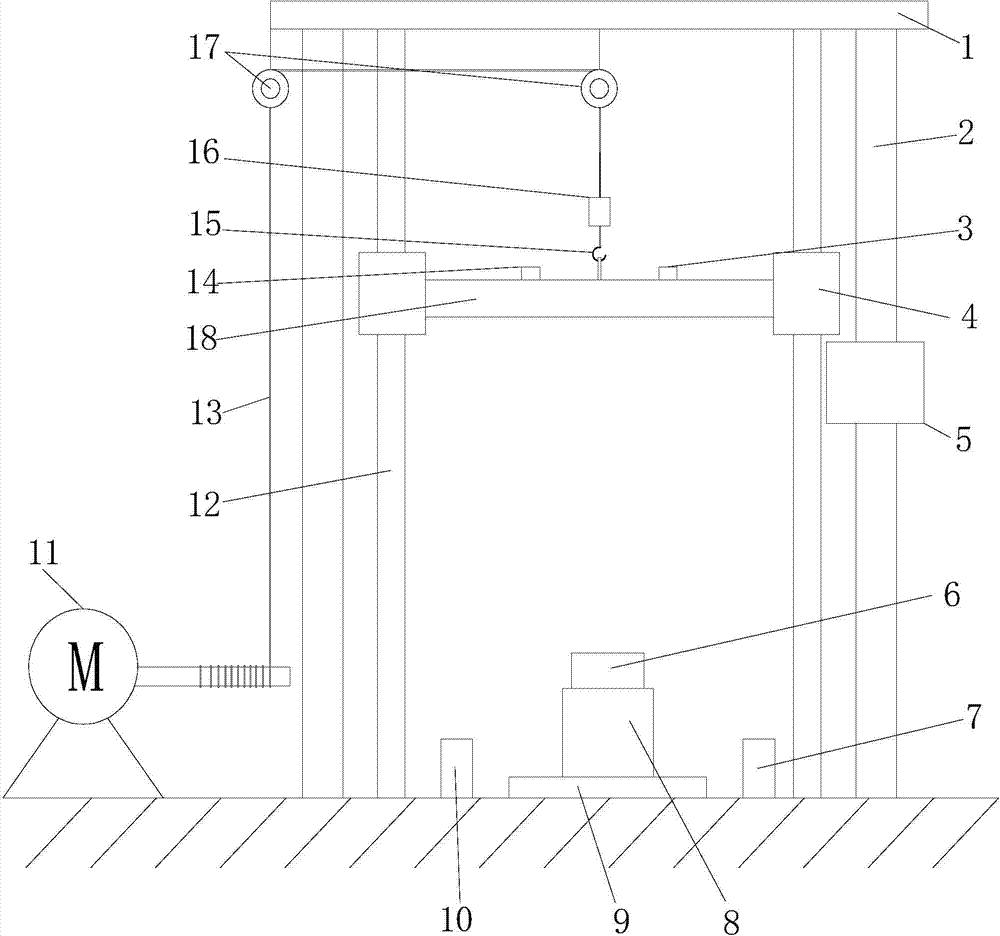

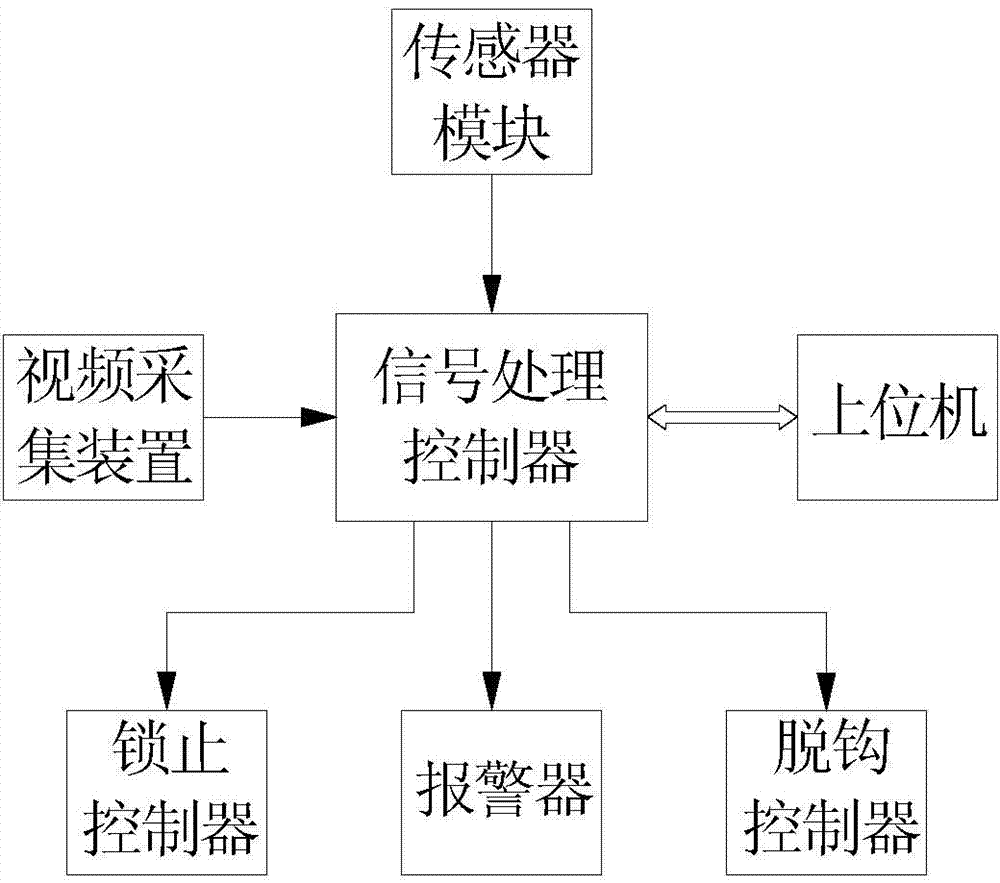

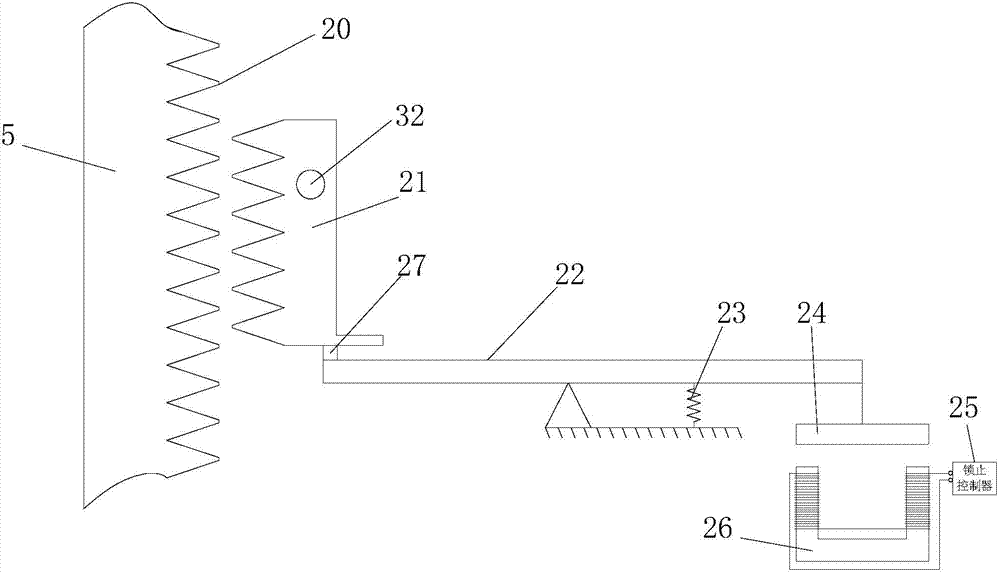

[0024] figure 1 It is a structural schematic diagram of the present invention, figure 2 It is the schematic circuit diagram of the present invention, image 3 It is the principle diagram of the failure protection device of the present invention, Figure 4 Be that the ratchet of fail-safe device of the present invention is in image 3 in the left view, Figure 5 It is a schematic diagram of the suspension assembly of the present invention, Figure 6 It is a structural schematic diagram of the vibration test of the present invention. As shown in the figure, a vertical drop impact test system provided by the present invention includes an adjustable mass load 18 for impacting the device under test 8, and is used to control the adjustable mass load. The suspension assembly at the height where the load 18 falls, the monitoring subsystem for monitoring the impact process, the support frame and the failure protection device, the monitoring subsystem controls the action of the sus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com