A Method for Predicting the Remanufacturability of Centrifugal Compressor Impellers Based on GBF Zone Size

A centrifugal compressor and manufacturable technology, applied in measuring devices, machine gear/transmission mechanism testing, instruments, etc., can solve the problems of indeterminate size, difficulty in accurately detecting the size and nature of internal cracks, low measurement accuracy, etc. The effect of accurate and reliable judgment results and reliable remanufacturability judgment results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

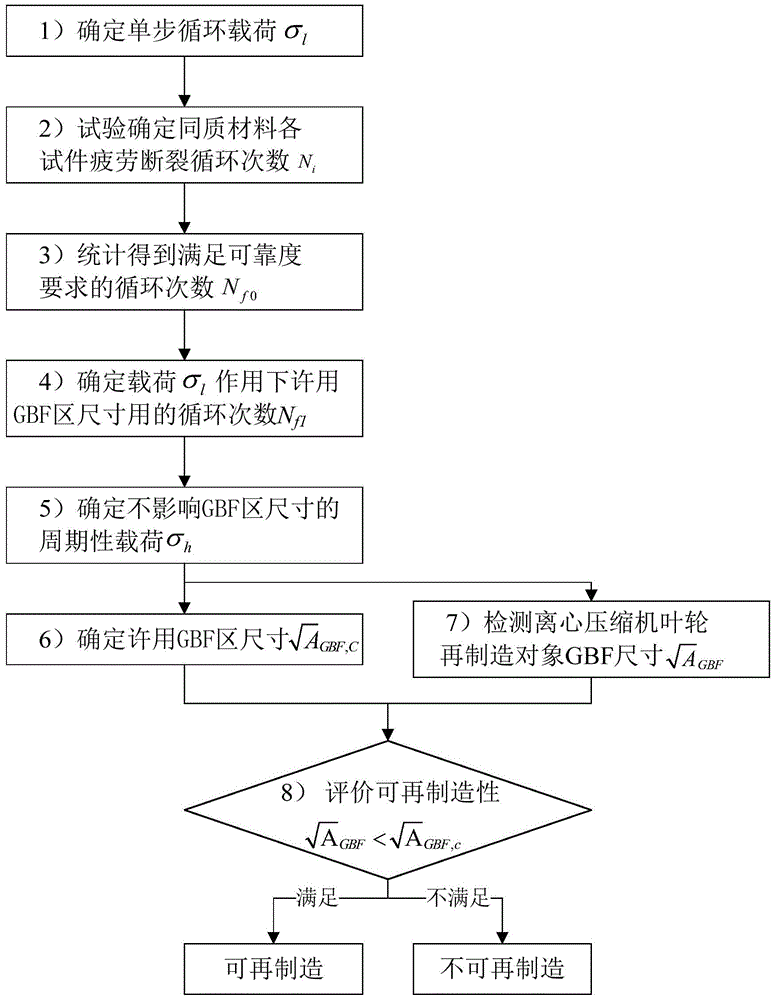

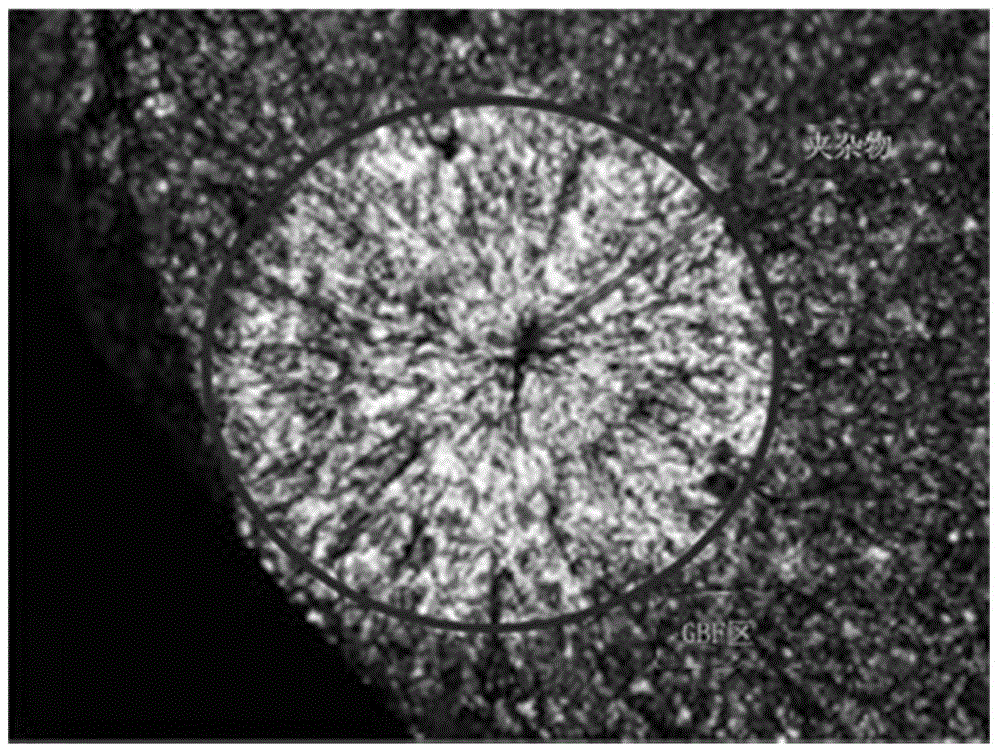

[0028] Example 1, such as Figure 1-Figure 3 Shown:

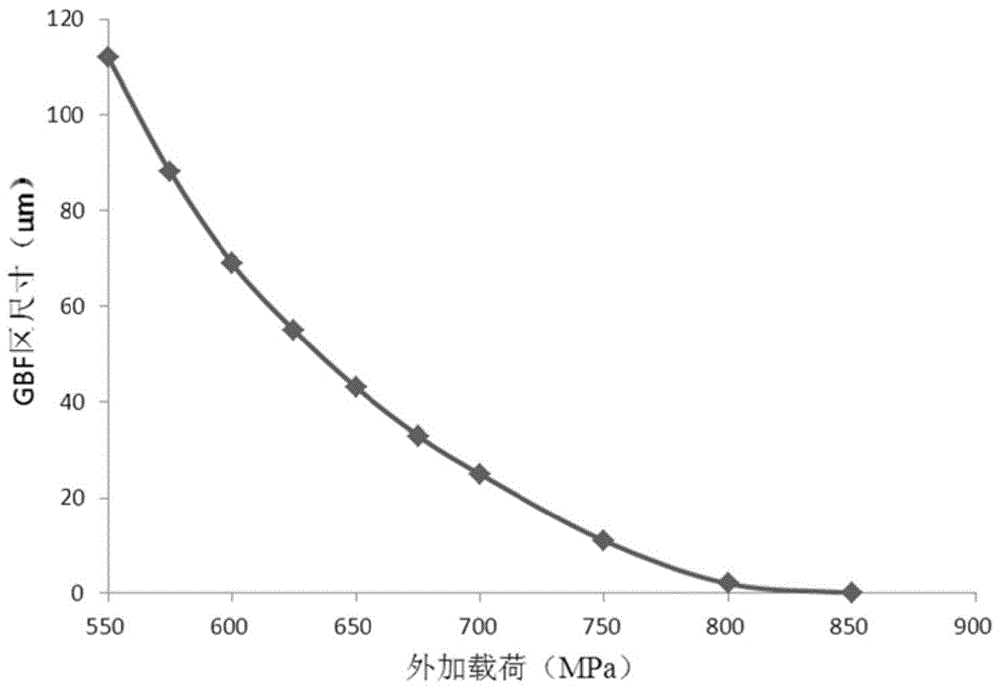

[0029] Step 1: Determine the single-step cyclic load σ l : According to the working condition of centrifugal compressor impeller, combined with Haigh diagram, the equivalent load is calculated as σ ε =580MPa, take σ ι =625MPa, σ ι -σ ε =45MPa, then the subsequent allowable GBF area size is relatively conservative and credible.

[0030] Step 2: Get the single-step equivalent load σ l The number of fatigue fracture cycles of each specimen under action N i: A group of FV520B specimens made of the same material as the centrifugal compressor impeller are subjected to fatigue loading on an ultra-high cycle fatigue testing machine. The fatigue testing machine used in this example is Shimadzu USF-2000 ultrasonic fatigue testing machine, and the resonance frequency is 20KHz. The resonance time is 150ms, the intermittent time is 150ms, and the stress ratio R=-1; the measured stress cycles of the FV520B specimen are 1.94E+07, 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com