Method for calculating twinning critical splitting stress by ebsd technique and Vickers hardness tester

A technology of critical shear stress and Vickers hardness tester, which is applied in the direction of testing material hardness, analyzing materials, strength characteristics, etc., can solve the problems of high cost, low popularity, and inability to reflect the critical shear stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

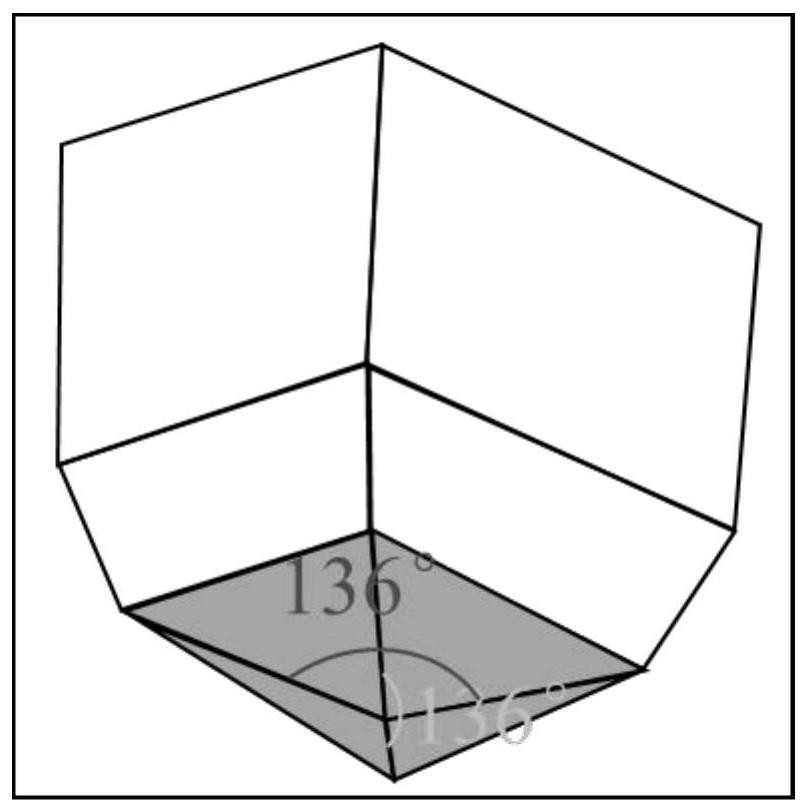

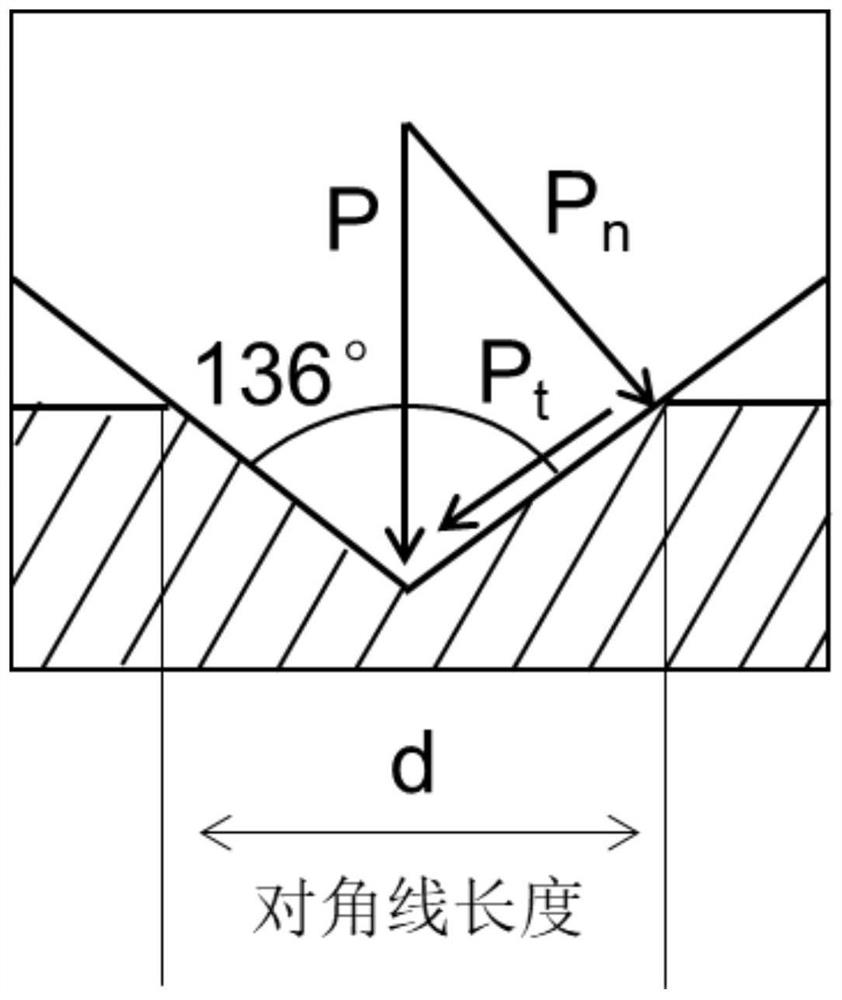

[0037] The method for calculating the critical shear stress of twins by EBSD technology and Vickers hardness tester comprises the following steps:

[0038] 1), EBSD sample preparation (to ensure the flatness of the sample):

[0039] First mount the sample on the sample mounting machine, and then pre-grind with 150#, 320#, 800#, 2000# water sandpaper in sequence. After removing deep scratches, perform vibration polishing on the automatic polishing machine. The polishing liquid is SiO 2 Nano-suspension solution, polished for about 1 hour, and finally a bright and trace-free polished surface with a mirror effect;

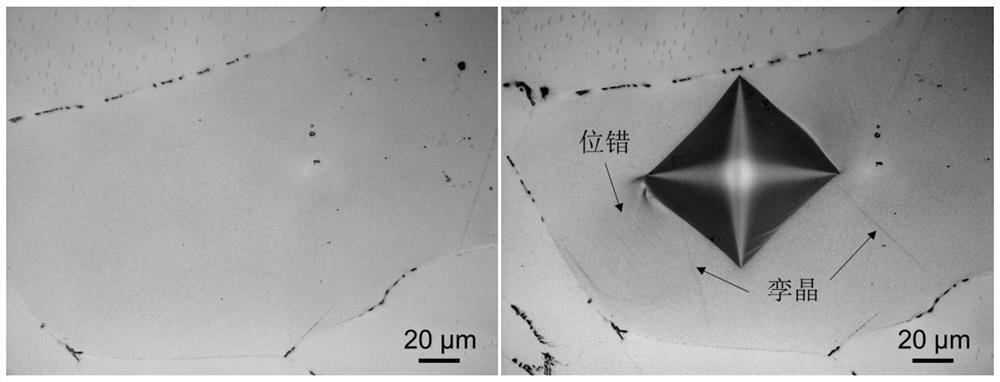

[0040] 2) Mark a certain position on the surface of the sample with Vickers hardness, and record the original morphology and crystal orientation of the area through metallographic microscope, scanning electron microscope and EBSD;

[0041] 3) Measure the hardness of the area with a Vickers hardness tester, change loads of different sizes (from 10-1000g), until twins ...

Embodiment 2

[0046] The method of calculating the critical shear stress of twins by EBSD technology and Vickers hardness tester, the critical shear stress of {11-21} twins is measured by the method described above for Zr-4 alloys in the quenched state in the β phase region .

[0047] The nominal composition of Zr-4 alloy is Zr-1.5Sn-0.2Fe-0.1Cr. This alloy has very low thermal neutron absorption cross section, high hardness, ductility and excellent corrosion resistance. It is mainly used in pressurized water reactors, Fuel cladding materials in boiling water reactors, heavy water reactors.

[0048] The first is the preparation of EBSD samples. EBSD samples are prepared after wire cutting samples, grinding and mechanical vibration polishing. Observe the shape change before and after the Vickers hardness indenter is pressed in through a metallographic microscope, such as image 3 shown. Keep under the load of 500g for 10 seconds, the hardness measured by Vickers hardness tester is 162HV, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com