Optical signal transmitting device

A transmission device and optical signal technology, applied in the direction of bundled optical fiber, etc., can solve the problems of loose optical fiber and affecting product performance, and achieve the effect of not easy to loose and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

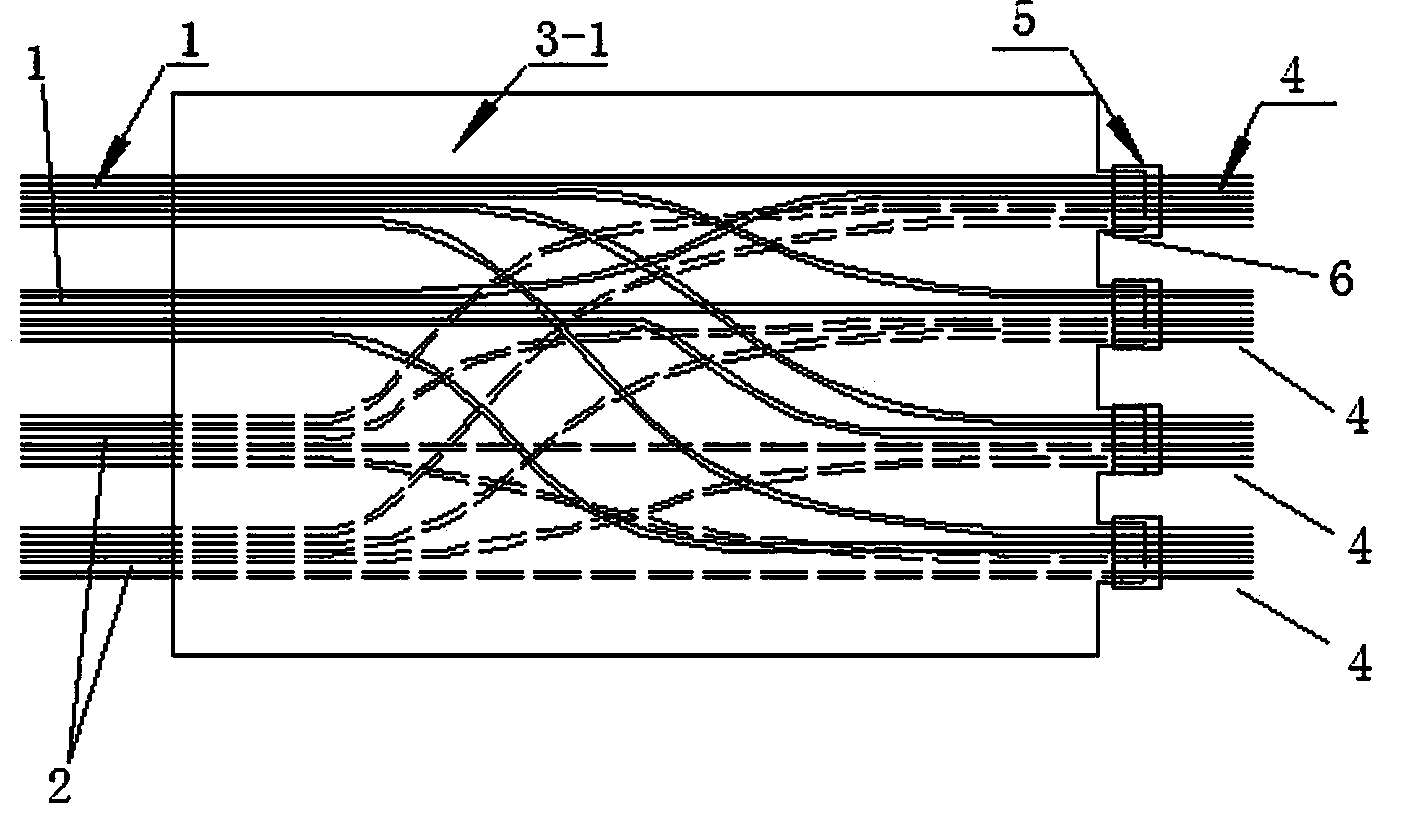

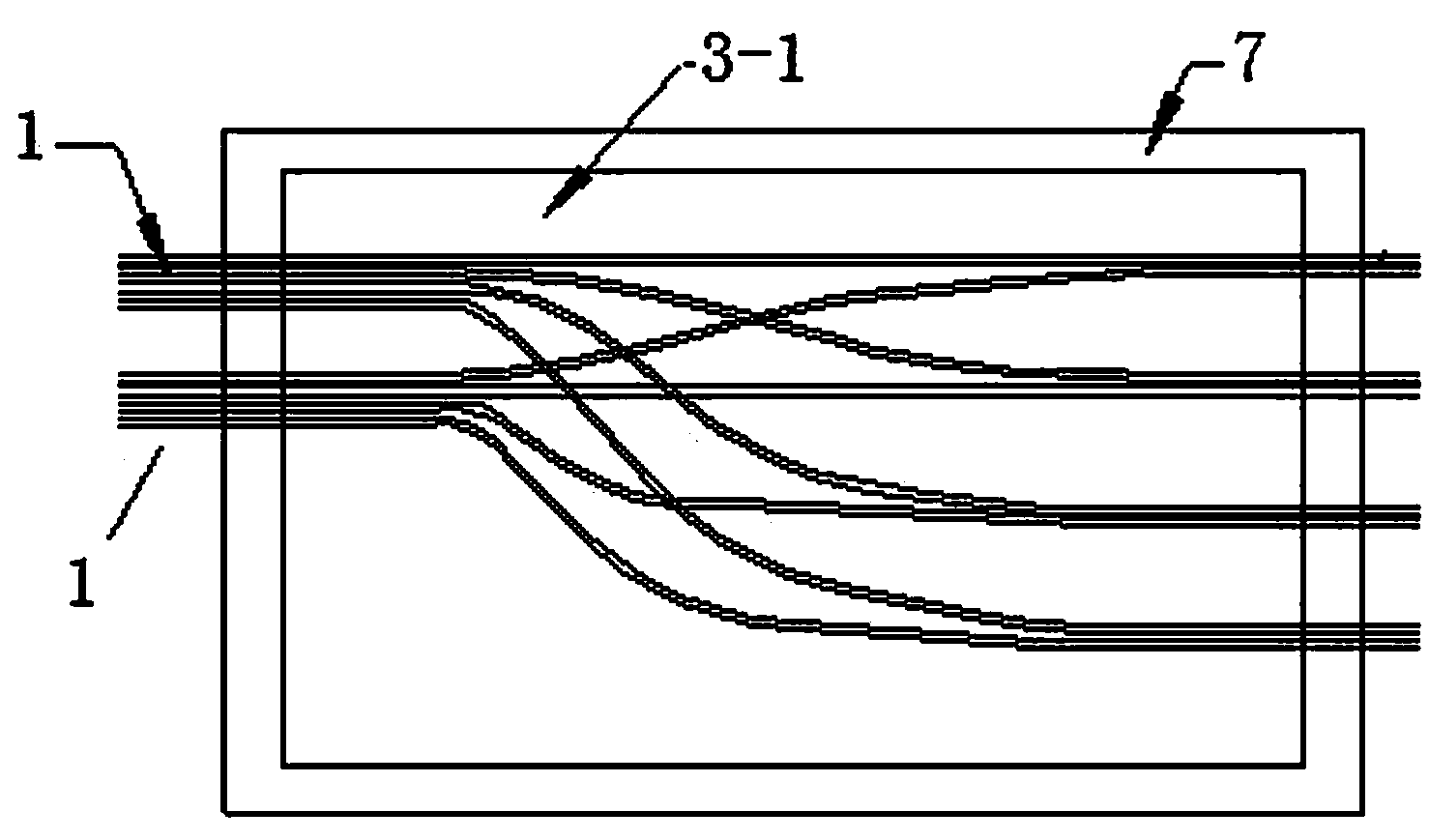

[0015] An example of an optical signal transmission device is Figure 1~5 Shown: Including the matrix whose thickness extends in the up and down direction. The matrix is a transparent film structure formed by curing the glue. The film structure is pressure-sensitive. The matrix itself composed of the film structure is flexible and bendable. Pressure-sensitive layers are formed on the upper and lower surfaces. Two fiber optic ribbons 1 are provided on the pressure-sensitive layer on the upper surface, and two optical fiber ribbons 2 are arranged on the pressure-sensitive layer on the lower surface. The optical fiber ribbons each include four optical fibers. The optical fiber inlet ends of the two incoming optical fiber ribbons 1 are arranged at intervals left and right, and the optical fiber inlet ends of the two incoming optical fiber ribbons 2 are arranged at left and right intervals. The corresponding optical fibers are recombined to form four outgoing fiber ribbons 4 arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com