Plane type waveguide optical branching device

A technology of waveguide light and splitters, applied in light guides, optics, instruments, etc., can solve the problems of short service life, prone to failure, troublesome maintenance, etc., and achieve increased long-term reliability, low splicing loss, and small footprint Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

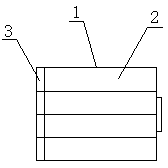

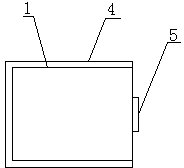

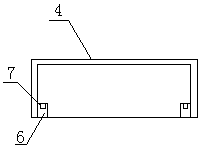

[0015] like figure 1 It is a schematic diagram of the structure of the present invention, a planar waveguide optical splitter, including a box body 1, a transverse integrated block 2 is arranged in the box body 1, and a vertical integrated block 3 is arranged on the transverse integrated block 2, so the The box body 1 is installed in an outer casing 4, and two sides of the inner casing 4 are provided with support bars 6, the support bars 6 are provided with guide wheel grooves 7, and both sides of the box body 1 are provided with guide wheel frames 8, The guide wheel frame 8 is provided with a guide wheel 9 .

[0016] According to another embodiment of the present invention, it further includes that the box body 1 is provided with a handrail 5 .

[0017] According to another embodiment of the present invention, it further includes that the number of integrated blocks on the vertical integrated block 3 is consistent with the number of horizontal integrated blocks 2 .

[0018]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com