Polarized light radiating device for optical orientation and polarized light radiating method for optical orientation

An irradiating device, a technology of polarized light, applied in polarizing elements, optics, optical elements, etc., can solve problems such as large degrees of freedom, and achieve the effects of improved productivity, simplified structure and operation, and uniform exposure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

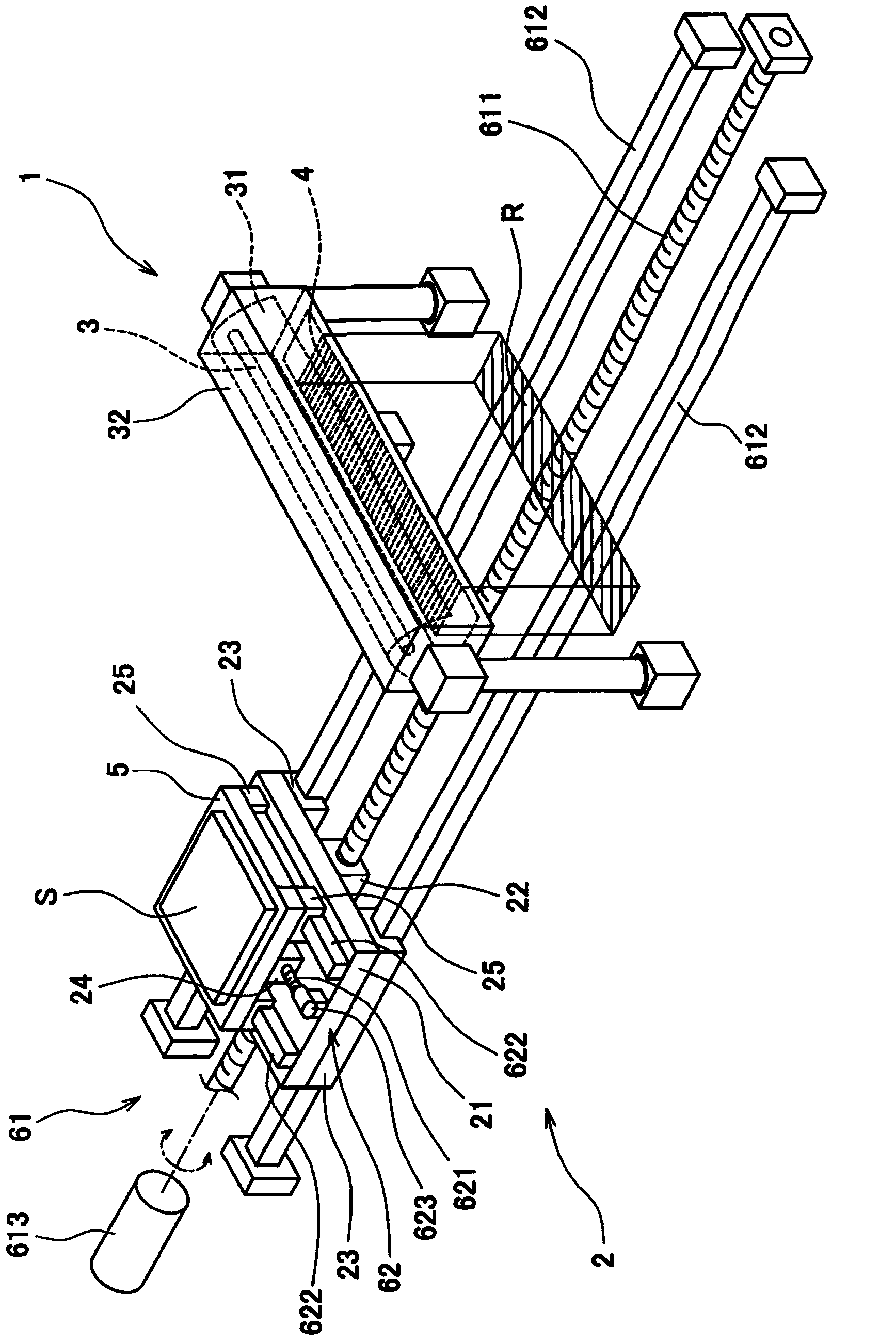

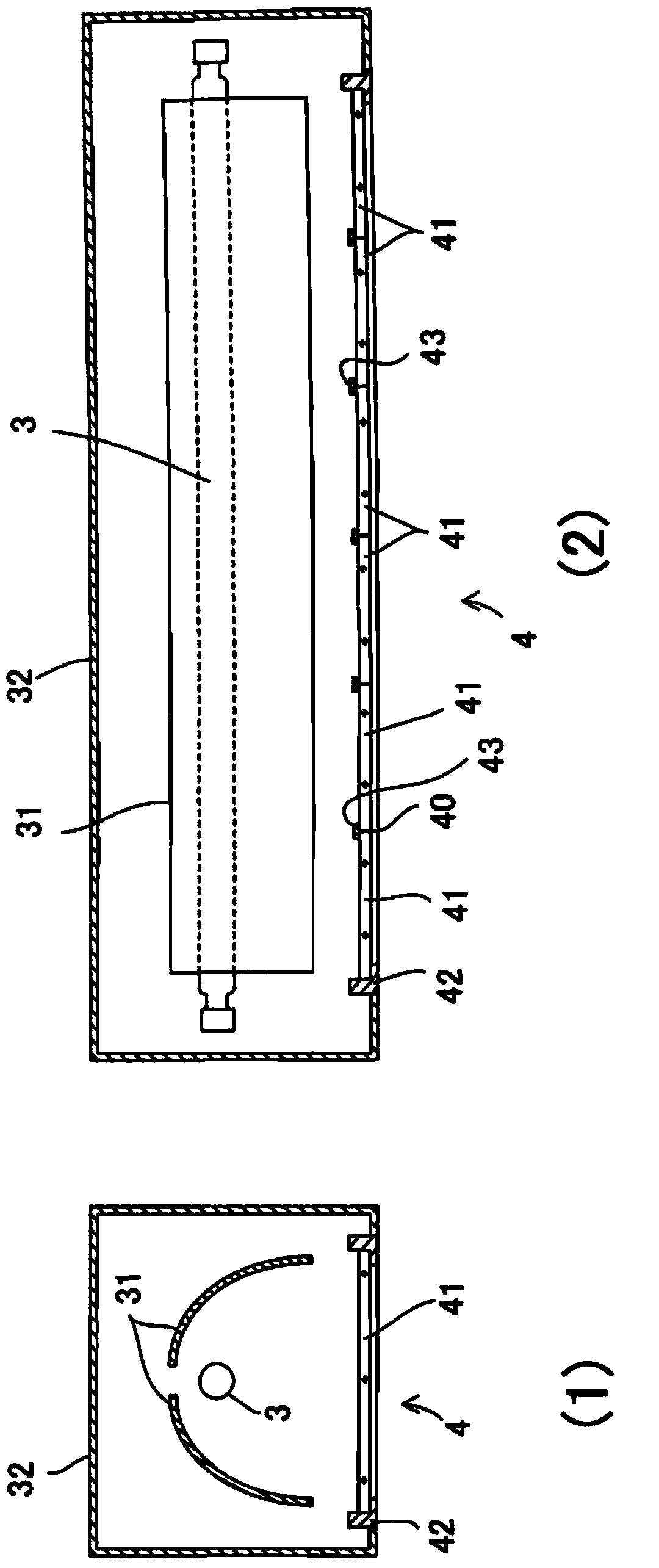

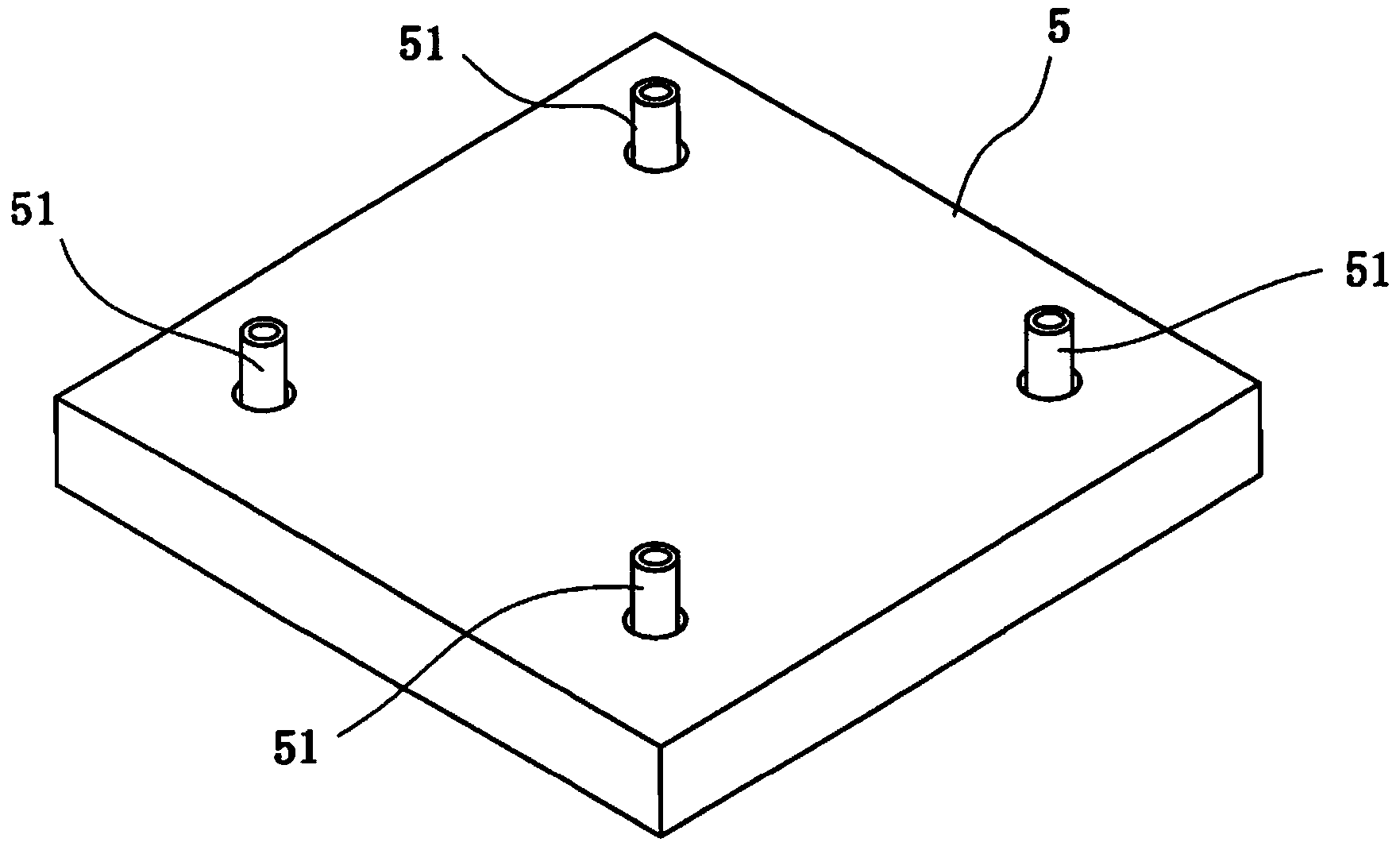

Method used

Image

Examples

Embodiment

[0139] Next, the result of the experiment which confirmed that the exposure amount became uniform by introducing the conveyance of the board|substrate S in the 2nd direction as mentioned above is demonstrated as an Example. Figure 13It is a figure which shows the result of the experiment which confirmed that the cumulative exposure amount becomes uniform by introducing the conveyance of the board|substrate S in a 2nd direction.

[0140] In this experiment, the width of the irradiated region R viewed in the second direction was 1500mm, the light source 3 was a high-pressure mercury lamp, and the average illuminance in the irradiated region R was about 130mW / cm 2 .

[0141] The width t of each polarizing element 41 is 150 mm, so the distance between the boundary lines is 150 mm. exist Figure 13 In (1), the exposure amount distribution is shown when the substrate S is conveyed in the same path in the forward path and the return path without moving in the second direction, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com