Industrial robot operation four-segment method collaborative planning method

A technology of industrial robots and operating sections, applied in the direction of electrical program control, digital control, etc., can solve the problems of increasing energy consumption, affecting production efficiency, low speed, etc., and achieve the effect of improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

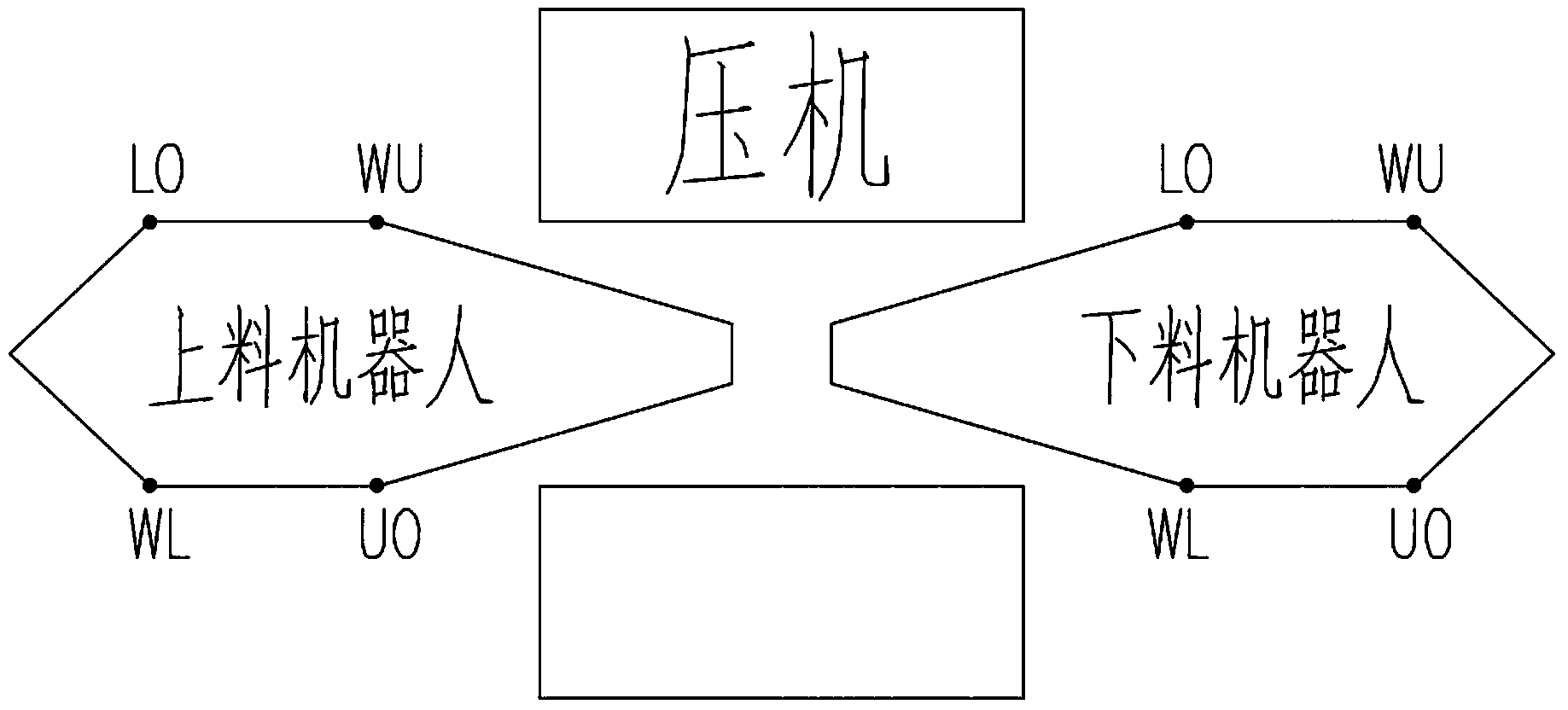

[0019] Attached below figure 1 The present invention will be further described.

[0020] The collaborative planning method of the industrial robot operation four-stage method includes the following steps:

[0021] (1) The action sequence of the industrial robot is divided into the loading operation section (LO), the unloading robot carries the workpiece processed by the previous machine tool to the next machine tool (WU), and the industrial robot enters the next machine tool for loading operations (UO) and after the industrial robot completes the loading operation, it goes to the previous machine tool to prepare for the unloading (WL) four sections; (2) Calculate the trajectory of the industrial robot by the formula S=(v×v) / (2×acc) During the teaching, the distance S between the unloading and loading waiting point of the industrial robot and the machine tool in the two stages of the unloading operation section (LO) and the industrial robot entering the next machine tool for l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com