Alternating motion type fire grate garbage incineration furnace

A waste incinerator, alternating motion technology, applied in the direction of incinerators, combustion methods, combustion types, etc., can solve the problems of grate wear and corrosion, garbage ash and slagging, etc., to achieve continuous and efficient combustion, reduce emissions, and breakdown low rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

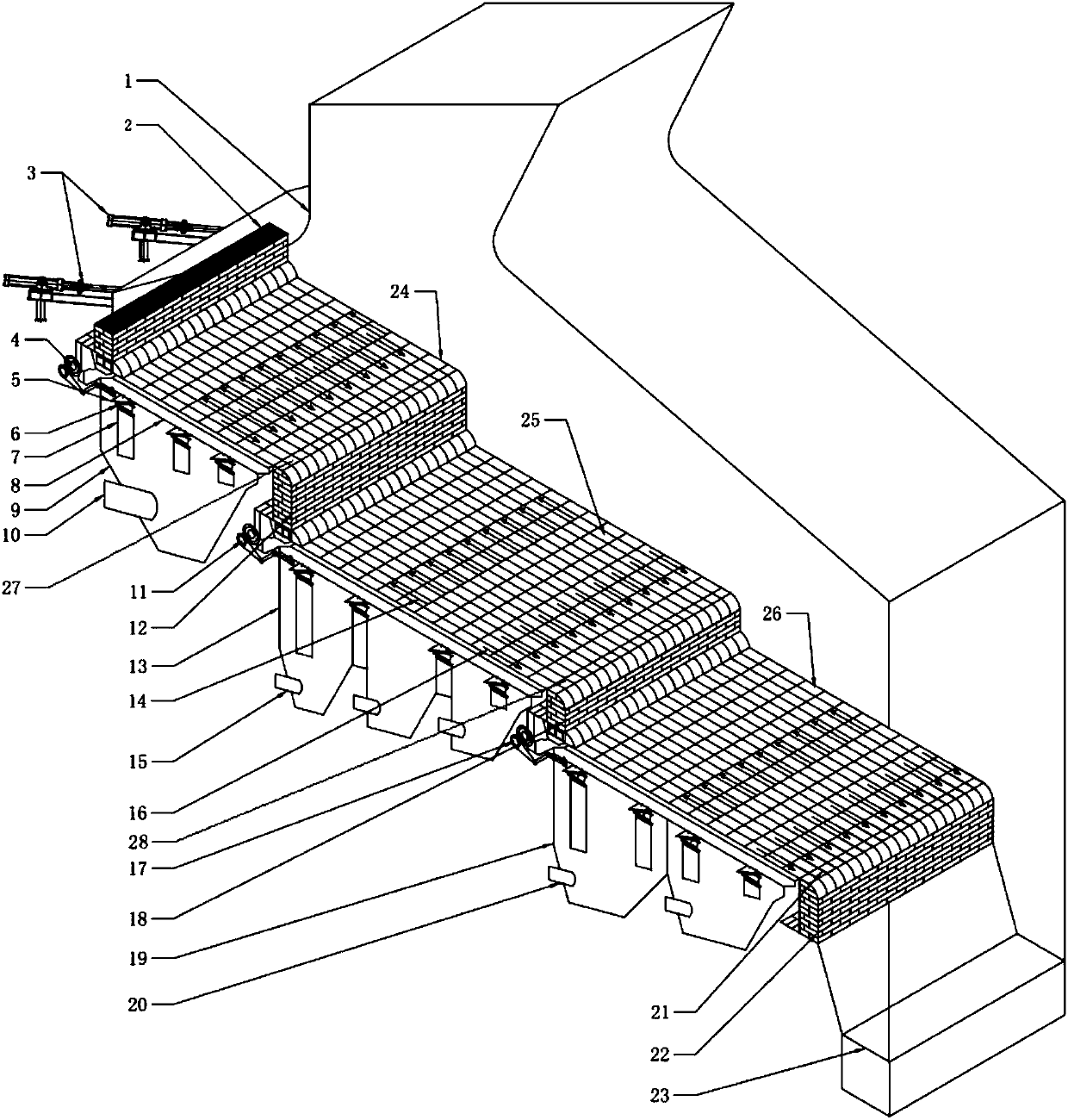

[0029] Such as figure 1 As shown, the alternate motion grate waste incinerator includes a furnace arch 1, a refractory brick platform 2, a feed pusher 3, a fire grate 14, a slag discharge device 23, a drying chamber 24, a combustion chamber 25 and an ember chamber 26 .

[0030] The furnace arch 1 is an arched structure, located above the drying chamber 24, the combustion chamber 25 and the ember chamber 26, and forms a closed cavity with the drying chamber 24, the combustion chamber 25 and the ember chamber 26.

[0031] The feed pusher 3 is arranged on the left side of the refractory brick platform one 2, and the amount of garbage entering the furnace is controlled by the feed pusher 3 .

[0032] Described fire grate 14 is divided into three levels, is set as fire grate one, fire grate two and fire grate three, and the fire grate of each leve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com