An online monitoring device and monitoring method for boiling degree of blast furnace gas boiler economizer

A technology of blast furnace gas and economizer, which is applied in the direction of measuring devices, instruments, electrical program control, etc., and can solve problems such as real-time detection and analysis of furnace gas without configuration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0049] Embodiment 1 online monitoring device:

[0050] In this section, the blast furnace gas boiler adopts a hierarchical arrangement of economizers to realize cascade utilization of energy and improve energy utilization efficiency. The economizer located upstream of the flue gas process in the blast furnace gas boiler flue is called the high temperature economizer here; the economizer located downstream of the flue gas process in the blast furnace gas boiler flue is called the low temperature economizer here device; it is the same in Embodiment 2 and will not be described again.

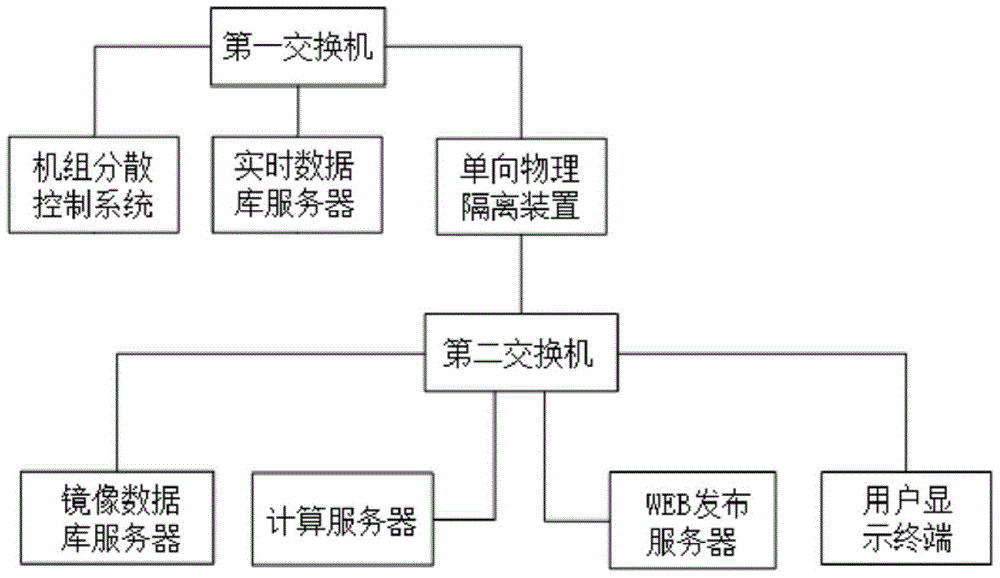

[0051] An on-line monitoring device for boiling degree of a blast furnace gas boiler economizer of the present invention includes a data acquisition unit, a one-way physical isolation device and a data processing unit, and the data acquisition unit and the data processing unit are connected through the one-way physical isolation device .

[0052] Among them, the data acquisition unit includes the...

Embodiment approach 2

[0054] Implementation mode 2 online monitoring method:

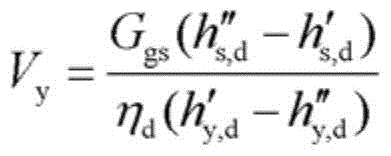

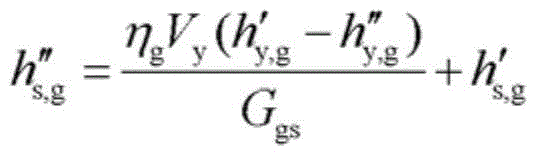

[0055] Based on the layout of the economizer in Embodiment 1 and the online monitoring device for the boiling degree of the economizer, the present invention provides an online monitoring method for the boiling degree of the economizer of a blast furnace gas boiler. The key points of its design are that it includes the following steps:

[0056] Step 1: The unit distributed control system of the data acquisition unit collects the operation data of the blast furnace gas boiler, stores the operation data in the real-time database server, and the real-time database server sends the received and stored operation data to the mirror database server for storage;

[0057] The decentralized control system of the unit and the high-temperature section economizer flue gas inlet temperature sensor arranged at the inlet end of the high-temperature section economizer flue gas side, and the high-temperature section economizer flue gas outle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com