Calibration device and calibration method for outer parameters of camera for photogrammetry

A calibration device and photogrammetry technology, applied in camera devices, image data processing, instruments, etc., can solve the problems of cumbersome calibration process, low imaging resolution, high cost of laser tracker, etc., and achieve convenient and simple use, high measurement accuracy, Measuring a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

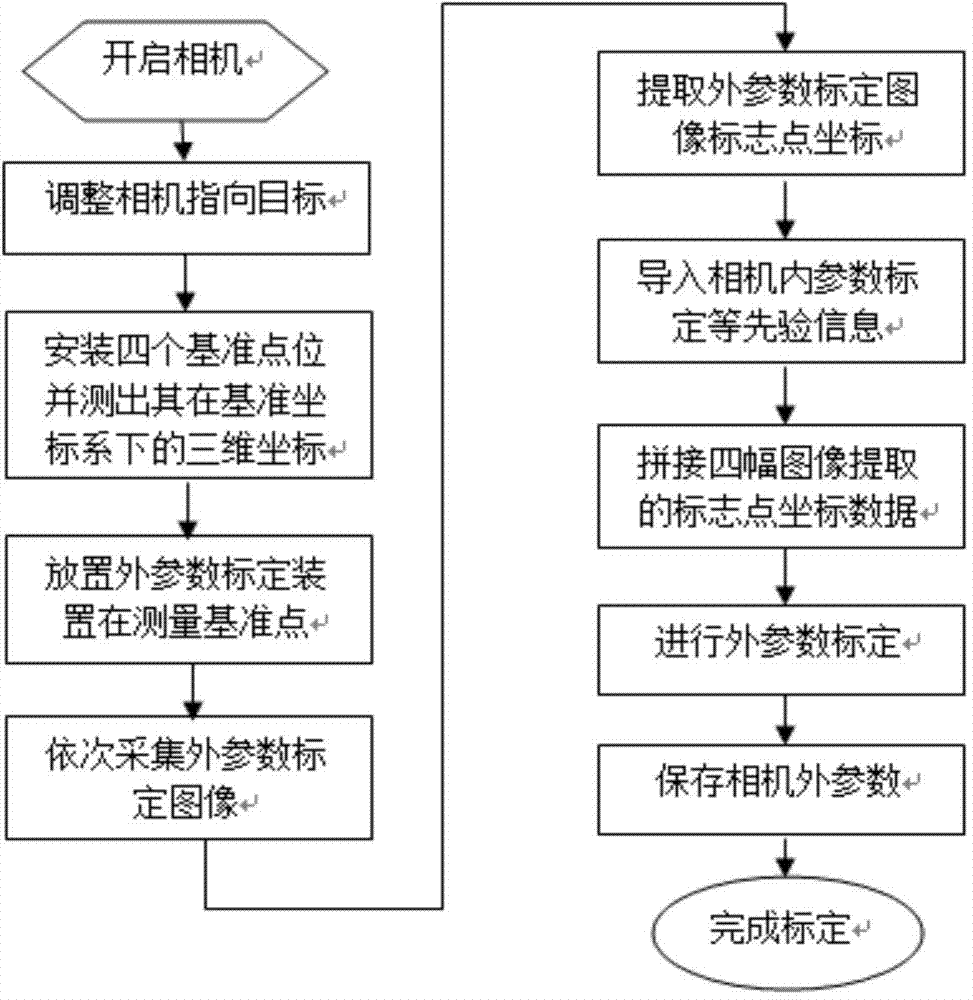

[0025] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

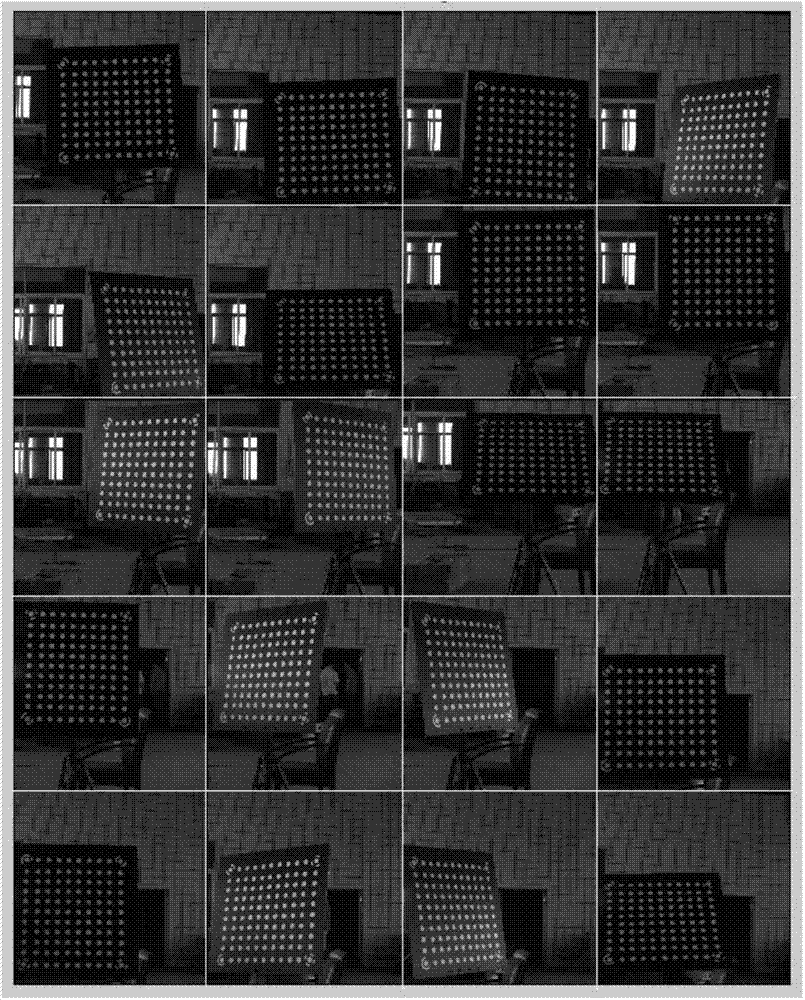

[0026] Step 1), carry out internal parameter calibration for each camera, that is, place the internal parameter calibration plate at a position 2 meters in front of the camera, such as image 3 As shown, change the orientation and attitude of the calibration board, collect 20 calibration board images, and extract the coordinates of the marker points of each image, as shown in Figure 4 As shown, perform internal parameter calibration and save the calibration results;

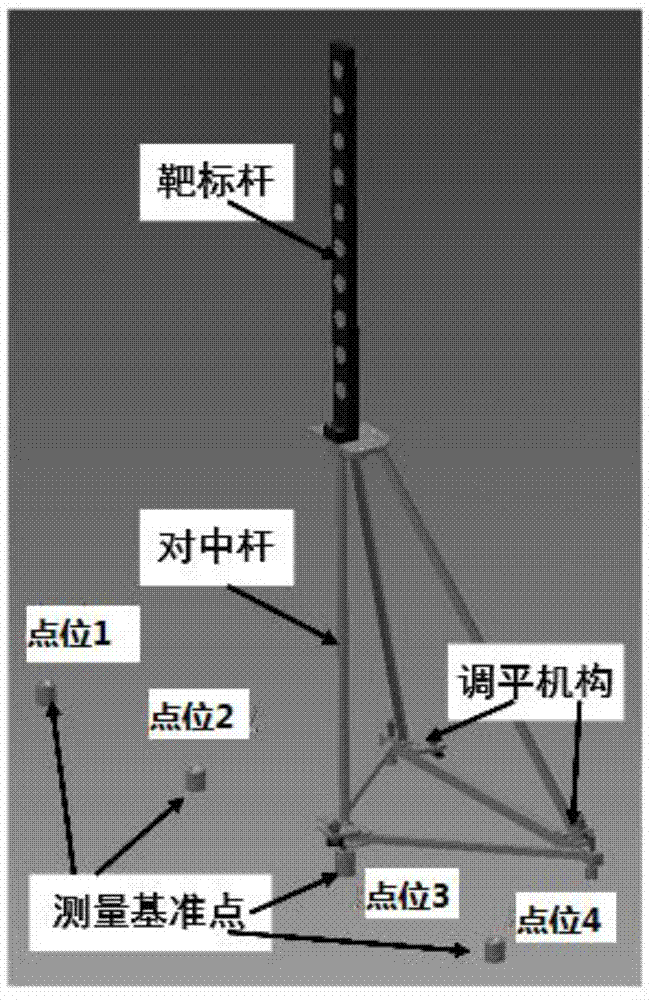

[0027] Step 2), according to the field of view of the camera, there are four measurement reference points embedded in the position of the calibration rod, and the coordinates of each measurement reference point in the reference coordinate system have been measured in advance, and the i-th reference point coordinate mark for:

[0028] P i ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com