Copper printing paper self pasting label belt without backing paper

A technology of self-adhesive labels and coated paper, which is applied in the field of labels, can solve the problems of poor products, not easy to tear, waste labels, etc., and achieve the effects of preventing oil immersion or damage, maintaining integrity, and increasing smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with accompanying drawing:

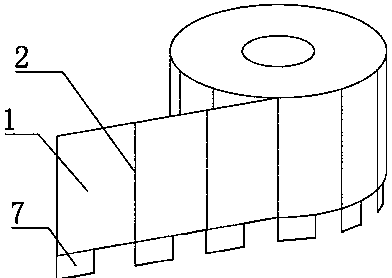

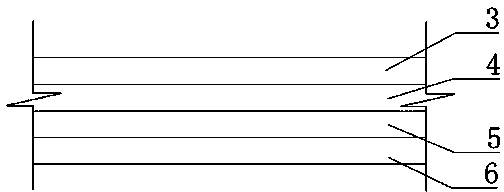

[0011] In the figure, 1. label; 2. tear line; 3. silicone oil layer; 4. coating layer; 5. coated paper; 6. adhesive layer; 7. easy-to-tear block.

[0012] Such as Figure 1-2 As shown, the label 1 and the label 1 are connected to each other by a tear line 2, and the label 1 includes a silicone oil layer 3, a coating layer 4, a coated paper 5 and an adhesive layer 6, and the printed surface of the coated paper 5 is covered with a Layer coating layer 4, the surface of the coating layer 4 is coated with a silicone oil layer 3, the adhesive layer 6 is on the reverse side of the printing surface of the coated paper 5, and a corner of the coated paper 5 of each label 1 extends an easy-to-tear block 7 , a tear line 2 is provided between the easy-to-tear block 7 and the label 1, and the label tape is rolled into a roll shape with the adhesive layer 6 inside, and the width of the u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com