Lifting device for lifting overhead ground wire on straight concrete pole

A technology of overhead ground wire and straight rod, applied in the direction of overhead line/cable equipment, etc., can solve the problems of heavy ground wire quality, hidden safety hazards in work, hidden dangers of equipment and personal safety, etc., so as to achieve fewer lifting device components and facilitate high-altitude operations. , the effect of simple installation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

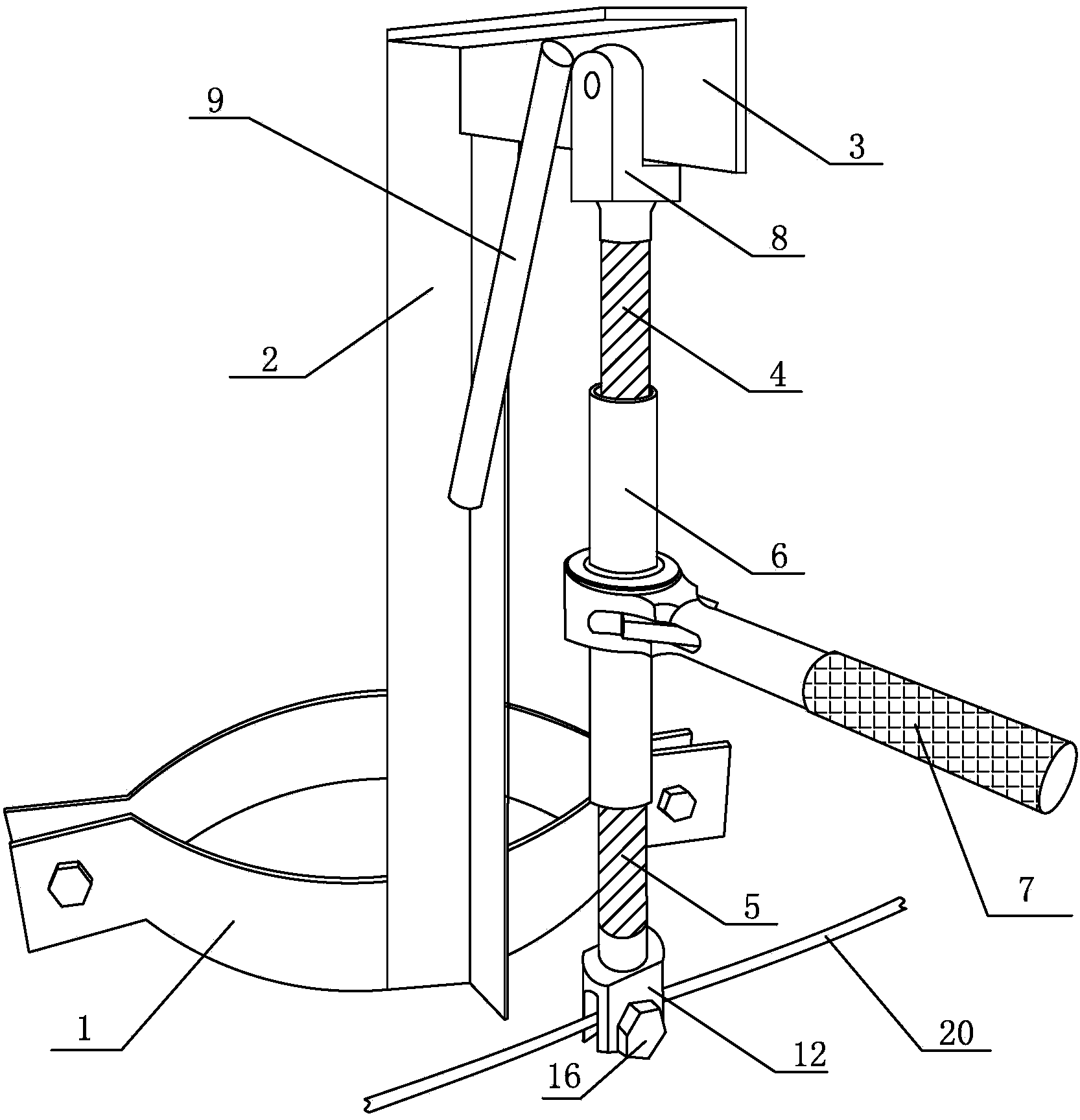

[0022] The utility model relates to a concrete rod linear rod overhead ground wire lifting device, including a fixing part, a supporting part and a lifting part.

[0023] The fixing member includes two hoops 1, which are iron hoops; the supporting member includes a vertical bracket 2 and a lateral suspension 3, and the vertical bracket 2 and the lateral suspension 3 are made of angle steel, and between the two Connect by welding (one end of the transverse suspension 3 is welded on the top of the vertical support 2), and use a welded steel bar 9 that is 45° to 60° with the vertical support 2 to increase the connection strength, and the bottom of the vertical support 2 is welded to the vertical support 2 On the hoop 1 of one of them, the lateral suspension 3 and the hoop 1 are respectively located on both sides of the vertical support 2, as figure 1 shown.

[0024] Described lifter comprises upper screw rod 4, lower screw rod 5, spiral tube 6 and adjustable to rotating handle 7...

Embodiment 2

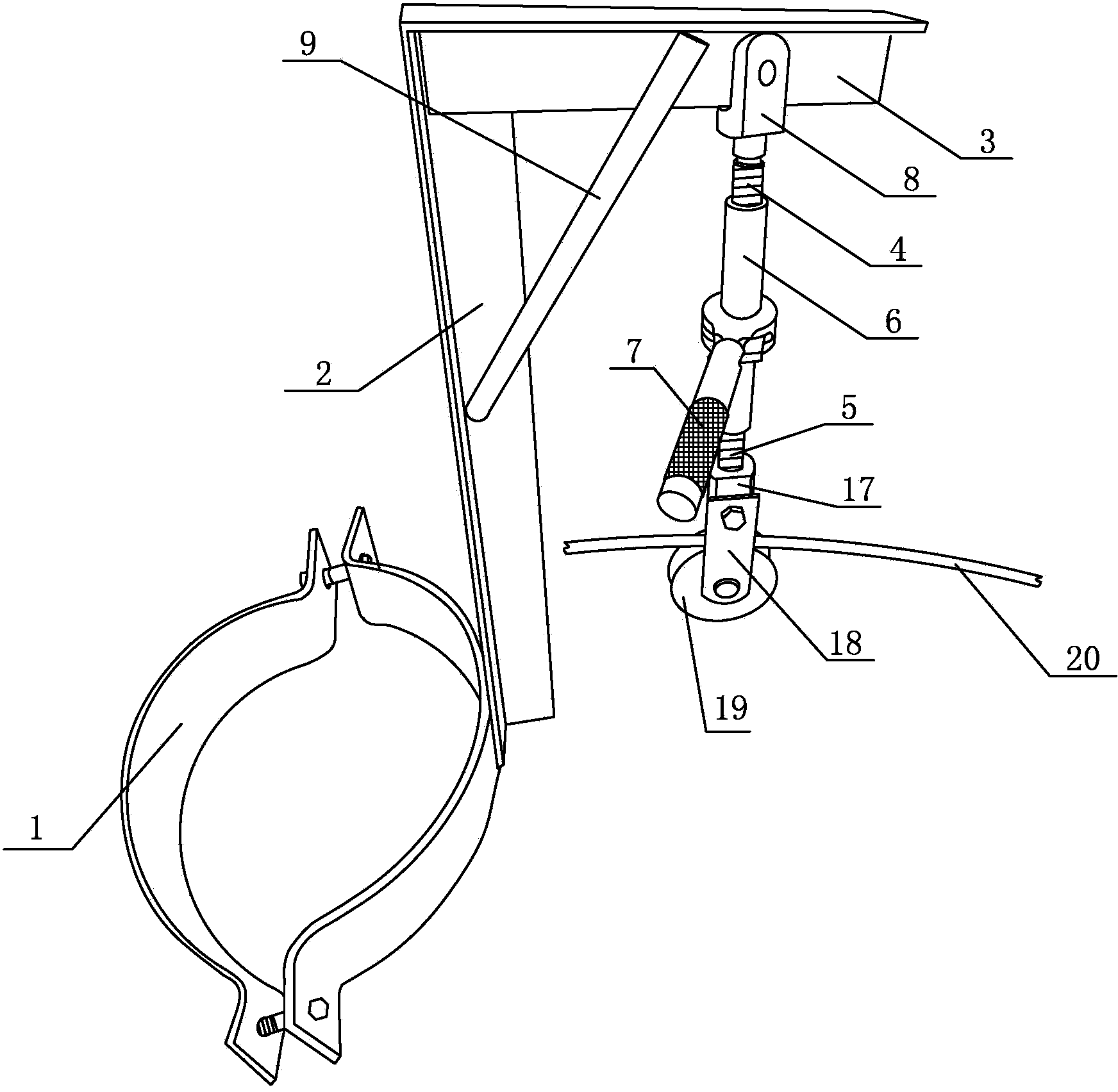

[0027] The utility model relates to a concrete rod linear rod overhead ground wire lifting device, including a fixing part, a supporting part and a lifting part.

[0028] The fixing member includes two hoops 1, which are iron hoops; the supporting member includes a vertical bracket 2 and a lateral suspension 3, and the vertical bracket 2 and the lateral suspension 3 are made of angle steel, and between the two Connect by welding (one end of the transverse suspension 3 is welded on the top of the vertical support 2), and use a welded steel bar 9 that is 45° to 60° with the vertical support 2 to increase the connection strength, and the bottom of the vertical support 2 is connected to the vertical support 2. On the hoop 1 of one of them, the lateral suspension 3 and the hoop 1 are respectively located on both sides of the vertical support 2, as figure 2 shown.

[0029] Described lifter comprises upper screw rod 4, lower screw rod 5, spiral tube 6 and adjustable to rotating han...

Embodiment 3

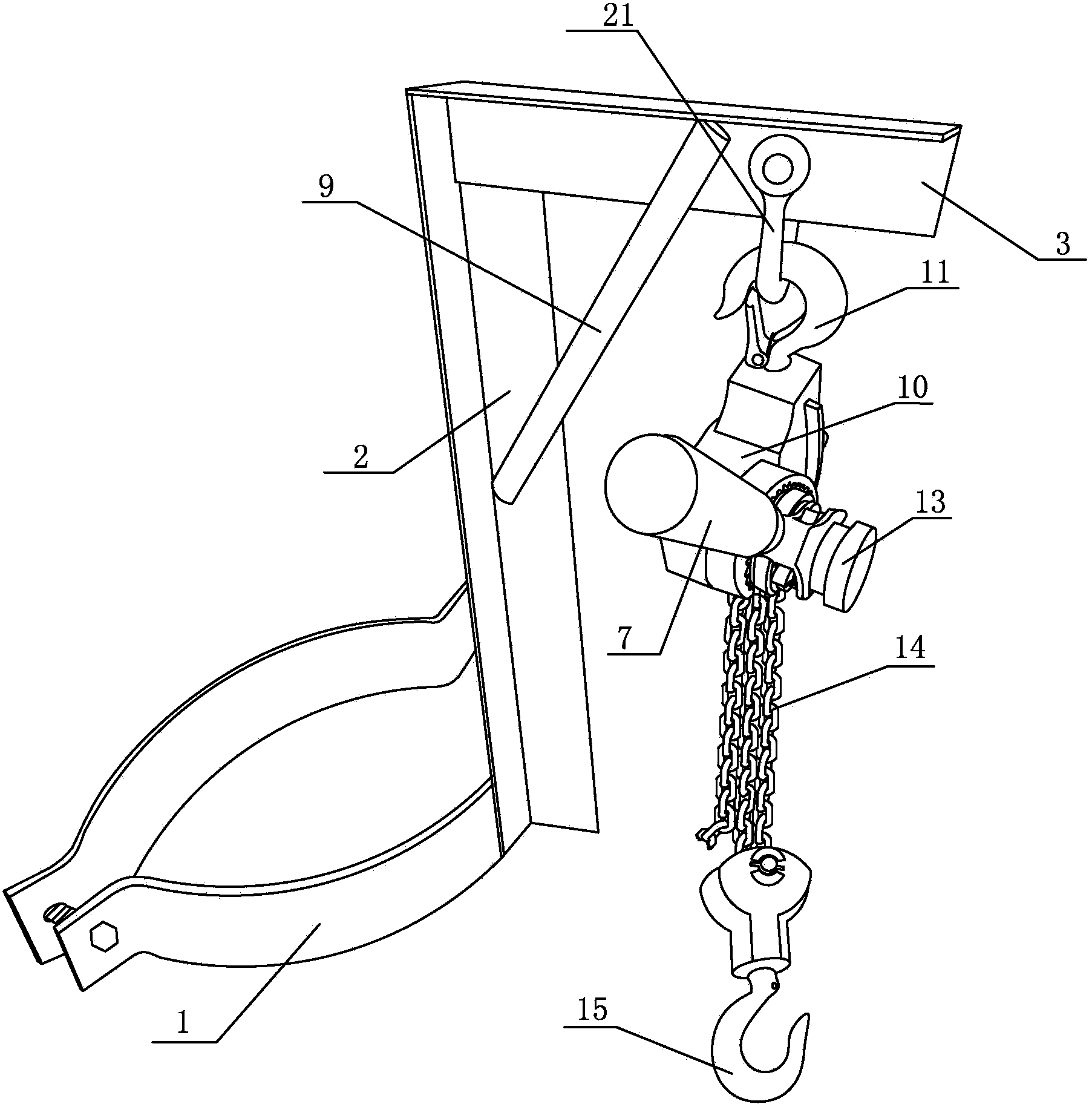

[0032] The utility model relates to a concrete rod linear rod overhead ground wire lifting device, including a fixing part, a supporting part and a lifting part.

[0033] The fixing member includes two hoops 1, which are iron hoops; the supporting member includes a vertical bracket 2 and a lateral suspension 3, and the vertical bracket 2 and the lateral suspension 3 are made of angle steel, and between the two Connect by welding (one end of the transverse suspension 3 is welded on the top of the vertical support 2), and use a welded steel bar 9 at 45° to 60° with the vertical support 2 to increase the connection strength, and the bottom of the vertical support 2 is affixed On one of the hoops 1, the transverse suspension 3 and the hoop 1 are respectively located on both sides of the vertical support 2, such as image 3 shown.

[0034] The lifting part is a lever block, and the lever block (purchased part) includes a gourd body 10, a hook 11, an adjustable rotating handle 7, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com