Segmented device for rotor butt joint assembly and method for conducting rotor butt joint assembly with device

A segmented, rotor technology, applied in the manufacture of stator/rotor body, etc., can solve the problems of accurate centering and positioning, high cost, labor and time-consuming, etc., and achieve the effect of fast centering and positioning, and accurate centering and positioning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to describe the technical features and functions of the present invention in detail and realize them according to the content of this specification, the following takes a segmented rotor of a steam turbine / combustion engine as an example to further describe the embodiment of the present invention.

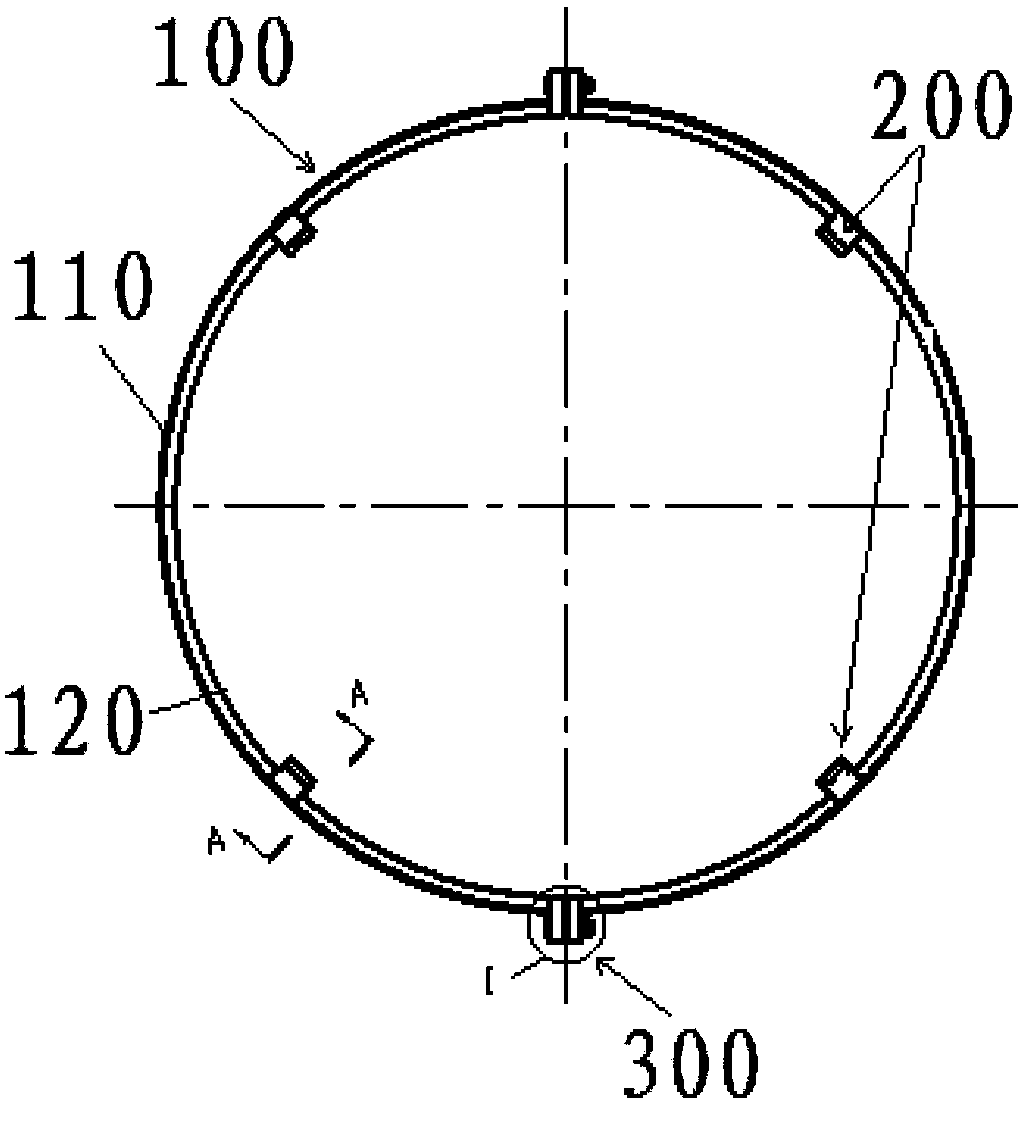

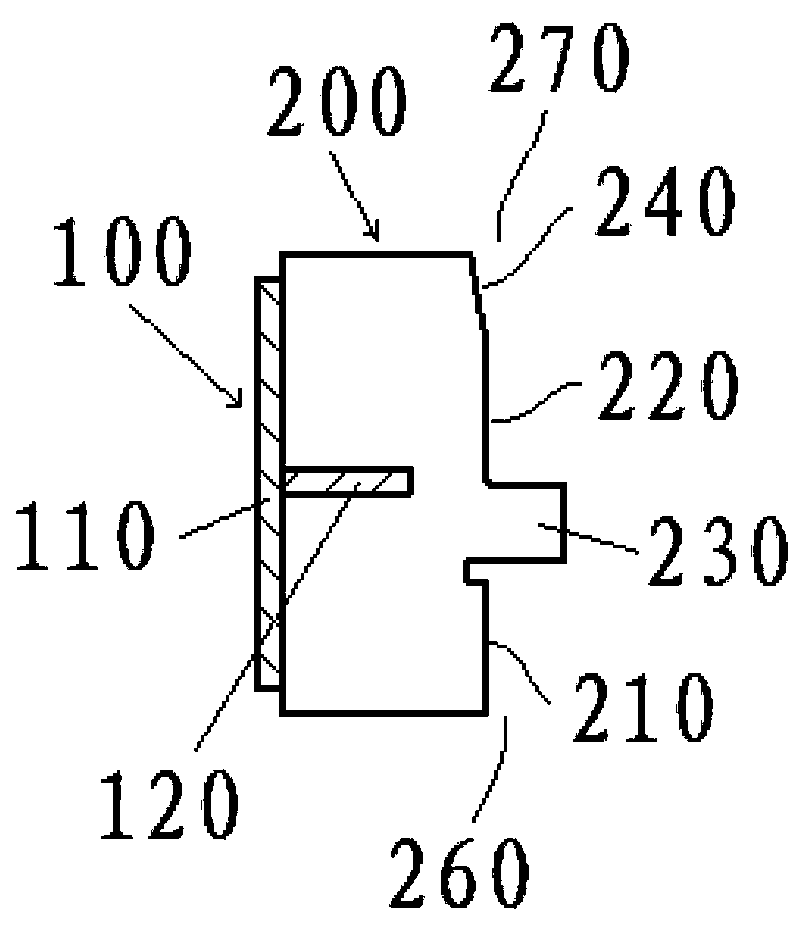

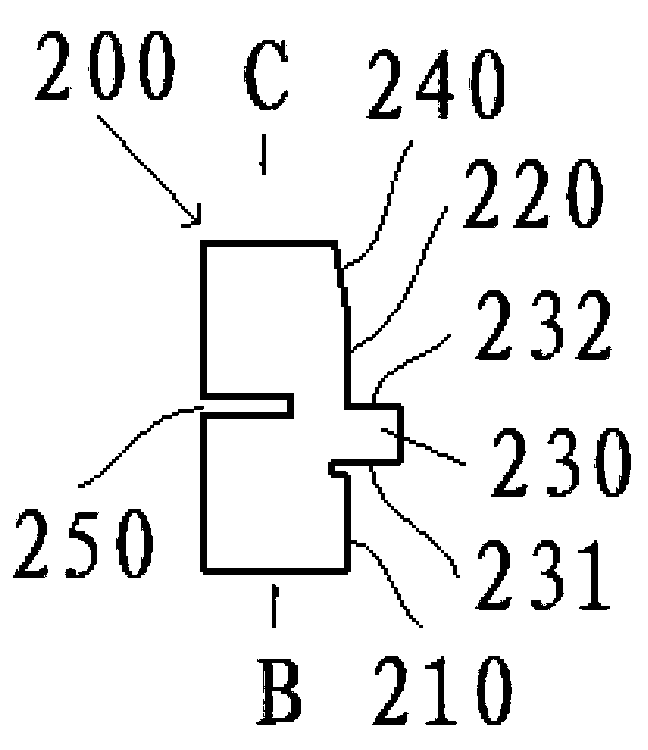

[0040] Figure 7 to Figure 9 It only shows a segmented rotor of the steam turbine / gas engine involved in the present invention in a schematic manner. Since the technical solution of the present invention does not involve other components and shape structures of the segmented rotor, Figure 7 to Figure 9 The figure only briefly shows the general structure of the segmented rotor divided into two butt-joint segments, obviously the shape and structure of the actual rotor is more complicated. Figure 7 to Figure 9 The lower shaft head 400 and the upper shaft head 500 of the segmented rotor are shown. For the convenience of description, the lower shaft head 400 of the segm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com