Three-dimensional circuit and manufacturing method thereof

A technology of three-dimensional circuit and manufacturing method, which is applied in the direction of printed circuit manufacturing, printed circuit, electrical components, etc., can solve the problems of long production cycle, low adhesion of copper layer, high cost, etc., and achieve the effect of reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be emphasized that the following description is only exemplary and not intended to limit the scope of the invention and its application.

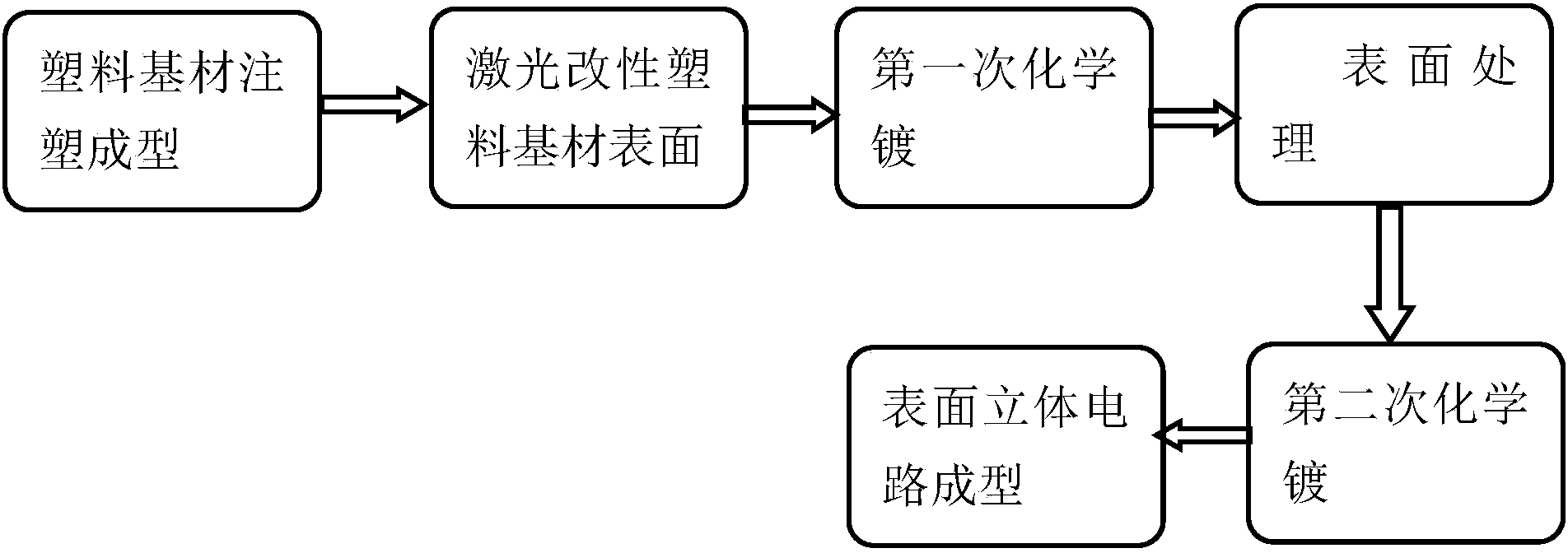

[0033] refer to figure 1 , in some embodiments, the step of three-dimensional circuit manufacturing process comprises:

[0034] Injection molding of plastic base material, laser modification of the surface of plastic base material, first chemical plating, surface treatment, second chemical plating, and surface post-treatment complete the final three-dimensional circuit molding. It should be understood that, in addition to general-purpose plastics, the present invention is also applicable to modified plastics containing modified components.

[0035] Step 1. Injection molding of plastic base material

[0036] Ordinary plastics are injection-molded according to the designed three-dimensional circuit structur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com