Method for mounting benzene hydrogenation engineering instrumentation

A technology for equipment installation and benzene hydrogenation, applied in electrical components, electrical components and other directions, can solve the problems of inconvenient, unreasonable and unscientific installation methods, and achieve the effect of flexible action and flexible mechanical transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0088] The present invention is further illustrated below by specific examples.

[0089] The installation method of instrumentation equipment for benzene hydrogenation engineering of the present invention, said instrumentation equipment includes instrument panel, instrument box, instrument cabinet and operating table, process detection instrument, process control instrument, analysis and detection instrument, sensor, transmitter, industrial computer The control system is characterized in that it comprises the following steps:

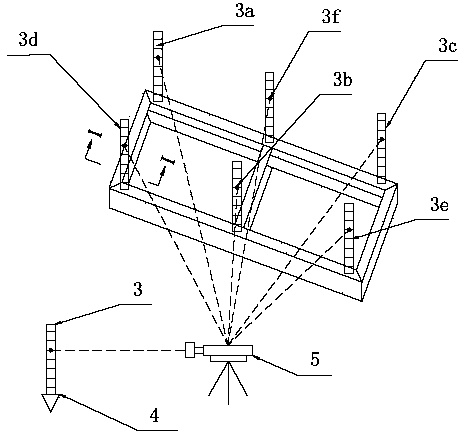

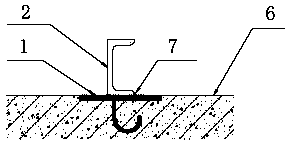

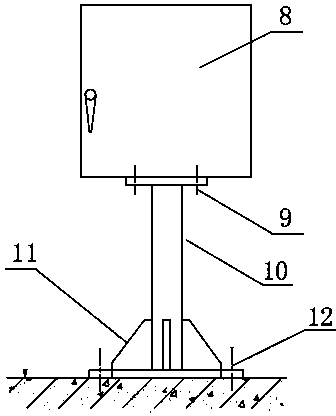

[0090] see now Figure 1 ~ Figure 4 , figure 1 It is a schematic diagram of the installation of the basic channel steel in the installation of the instrument panel, the instrument box, the instrument cabinet and the operating table of the embodiment of the present invention, figure 2 for figure 1 I-I sectional view in, image 3 It is a schematic diagram of installation of a floor-standing instrument box according to an embodiment of the present inv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com