Drum type washing machine

A drum-type washing machine and drum technology, which is applied to other washing machines, control devices of washing machines, washing devices, etc., can solve problems such as inability to operate, movement of washing machines, and increased vibration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

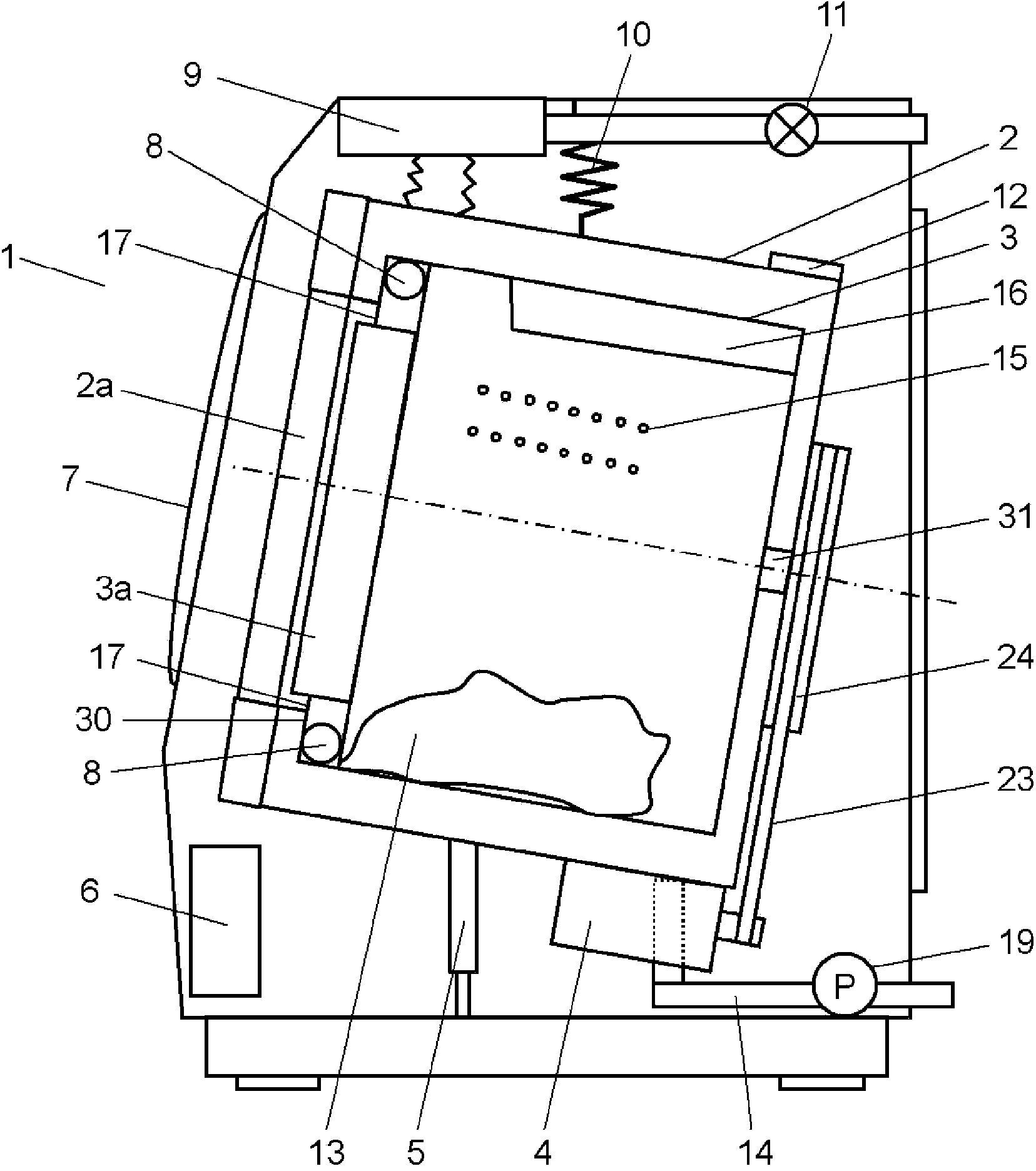

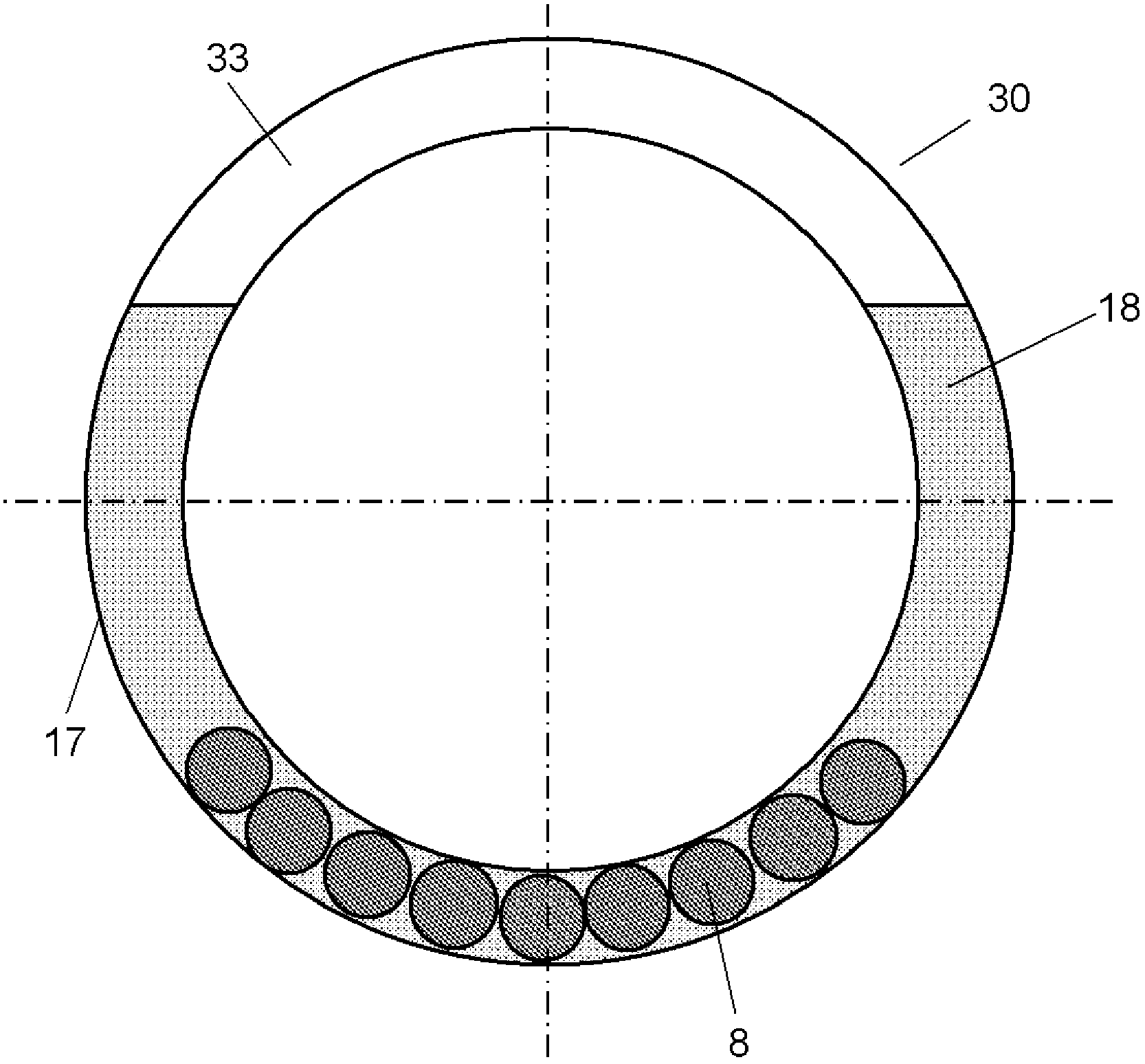

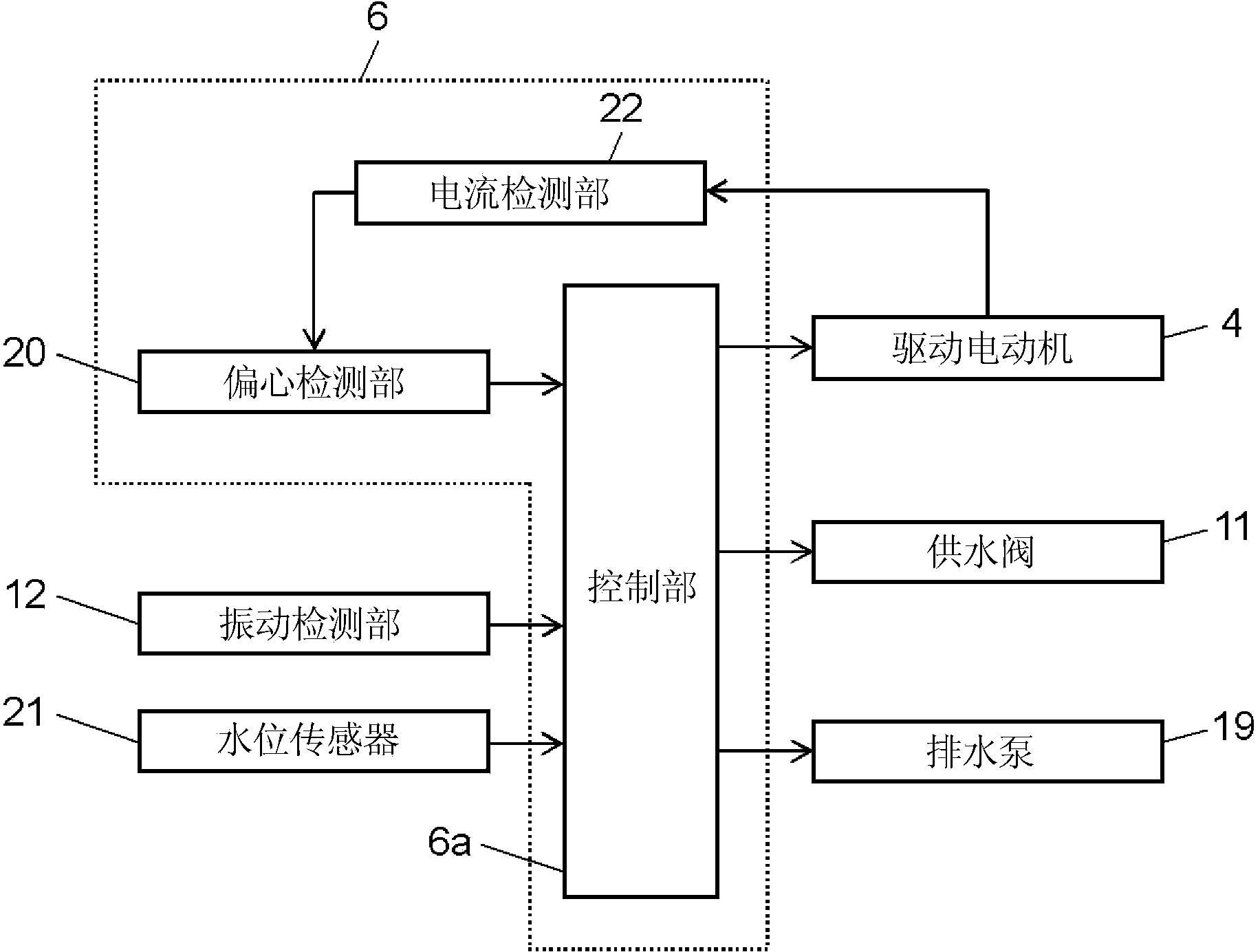

[0030] figure 1 It is a block diagram of the front-loading-type washing machine of Embodiment 1 of this invention. figure 2 It is a schematic diagram of the ball balancer which concerns on 1st Embodiment of this invention.

[0031] A bottomed cylindrical water tank 2 is accommodated inside the drum type washing machine 1 . A bottomed cylindrical drum 3 is accommodated inside the water tank 2 . On the front side of the front-loading-type washing machine 1, an opening 3a communicating with the inside of the drum 3 through the opening 2a of the water tank 2 is formed. The drum 3 is arranged so that the rotating shaft 31 that rotatably supports the drum 3 is inclined downward from the front side toward the back side. The opening part 2a is made into the front side, and the water tank 2 is arrange|positioned obliquely along the drum 3. As shown in FIG. By tilting the rotating shaft 31, the opening on the front side of the water tank 2 can be arranged on the upper side, and th...

no. 2 approach

[0056] Another mode of the starting process of the rotational speed of the drum will be described.

[0057] The control unit 6a of the front-loading-type washing machine according to the second embodiment of the present invention performs the following control. That is, the control unit 6a determines that the drum is being accelerated from the eccentric amount and eccentric position of the drum 3 before acceleration and the unbalance of the drum 3 during acceleration and the eccentric amount when the rolling elements 8 rotate together, based on the signal obtained by the eccentricity detecting unit 20 . Each rolling body is the position of the rolling body 8. Then, the drive motor is controlled so that the unbalance of the rolling element 8 and the laundry is at a position facing each other. Other structures refer to the first embodiment of the present invention. Next, different points will be described.

[0058]As shown in the first embodiment of the present invention, in ...

no. 3 approach

[0070] Next, use Figure 7 The operation and function of the front-loading washing machine according to the third embodiment of the present invention will be described.

[0071] In addition, the same reference numerals will be attached to the same components as those in the first and second embodiments of the present invention, and detailed descriptions will be omitted.

[0072] Figure 7 It is a figure which shows the order of the rotation speed of the front-loading-type washing machine which concerns on 3rd Embodiment of this invention.

[0073] First, when the front-loading washing machine 1 performs dehydration after draining, a driving voltage is applied to the driving motor 4 according to an instruction from the control unit 6a. The drive motor 4 is rotated from a low speed to a high speed to gradually increase the rotation speed of the drum 3 . At this time, the drive motor 4 is a permanent magnet type synchronous motor, so the rotor position of the drive motor 4 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com