Hydraulic hybrid swing drive system for excavators

A technology of slewing drive and hydraulic circuit, which is applied to hybrid vehicles, motor vehicles, earth movers/excavators, etc., and can solve problems such as increased cooling costs and hydraulic fluid heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

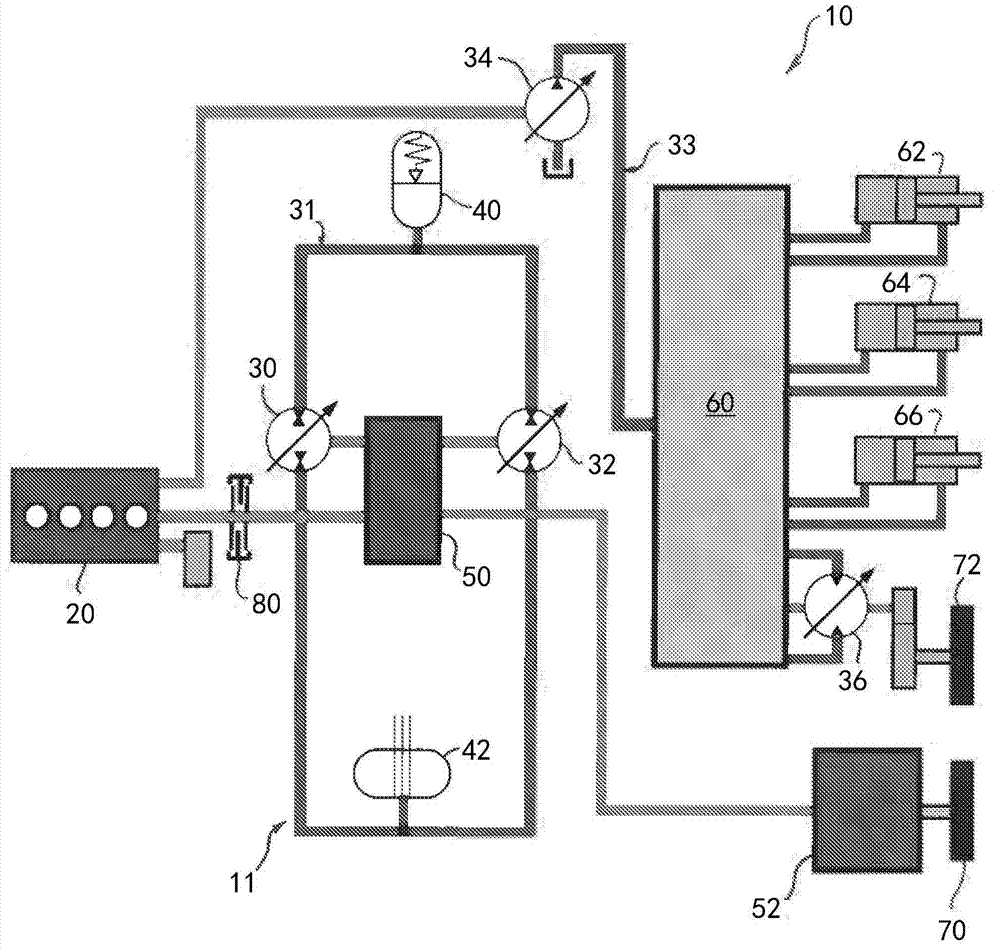

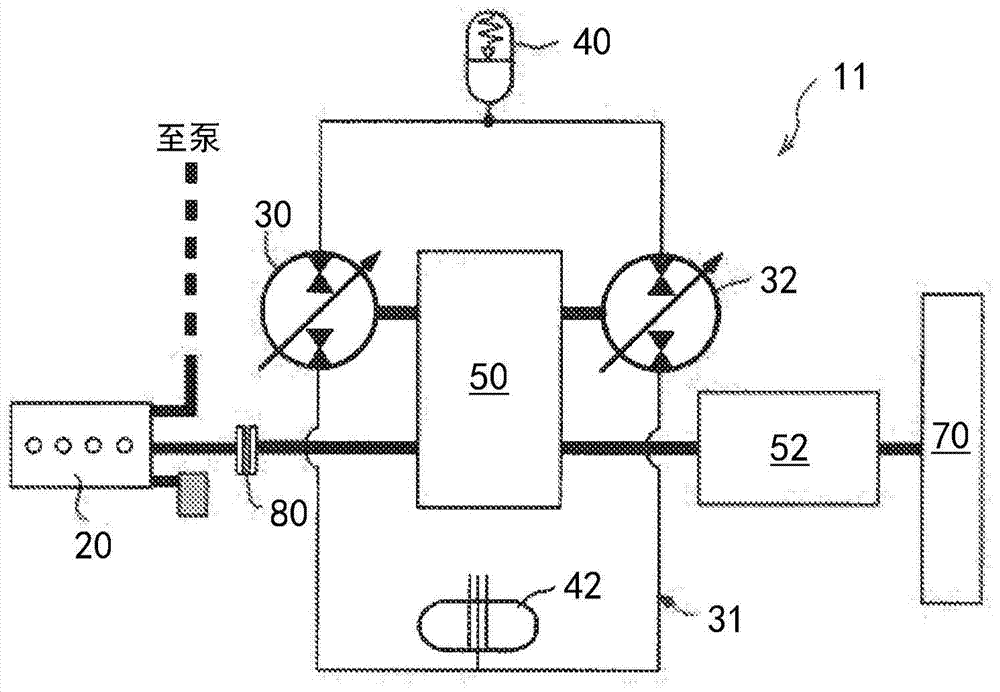

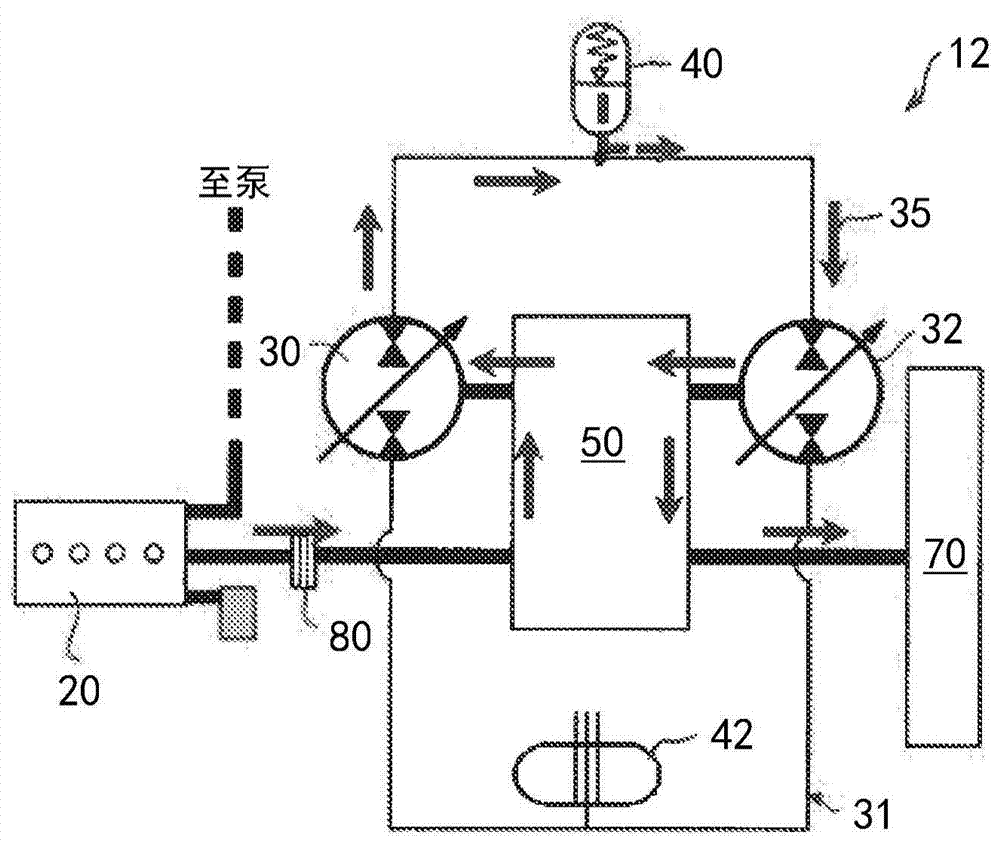

[0021] refer to figure 1 , which shows a hydraulic hybrid drive system 10 for an excavator, the hydraulic hybrid drive system 10 including a hydraulic swing drive system 11 . A hydraulic drive system 10 utilized in an excavator includes the upper structure, chassis, swing, boom, arm and bucket of the excavator (not shown). The hydraulic swing drive system 11 includes a prime mover 20 . Prime mover 20 is preferably an internal combustion (IC) engine, although other prime movers such as gas turbines, electric motors, and fuel cells may also be used. The prime mover 20 is mechanically connected to the first hydraulic unit 30 and the second hydraulic unit 32 , and is mechanically connected to the swing mechanism 70 . The hydraulic units 30, 32 are preferably of the variable displacement type and are reversible, and can function as either pumps or motors, and are referred to herein as hydraulic units or hydraulic pump / motors. By way of example, the hydraulic unit may be an axial...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap