Automatic pendulum screw tightening machine and its working method

An automatic, silk machine technology, applied in metal processing, manufacturing tools, metal processing equipment, etc., can solve the problems of low production efficiency, high labor intensity, high manufacturing cost, etc., to improve production efficiency, reduce labor intensity, and reduce labor cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] In order to further illustrate the principle and structure of the present invention, the preferred embodiments of the present invention will now be described in detail with reference to the accompanying drawings.

[0048] Generally, a layer of wooden floor is laid at the bottom of the box body of the container. In order to fasten the wooden floor on the bottom frame of the container, the present invention adopts the automatic pendulum nail and tightening function of the automatic pendulum nail tightening machine to compress the screws on the bottom frame. Container on wooden floor and underframe.

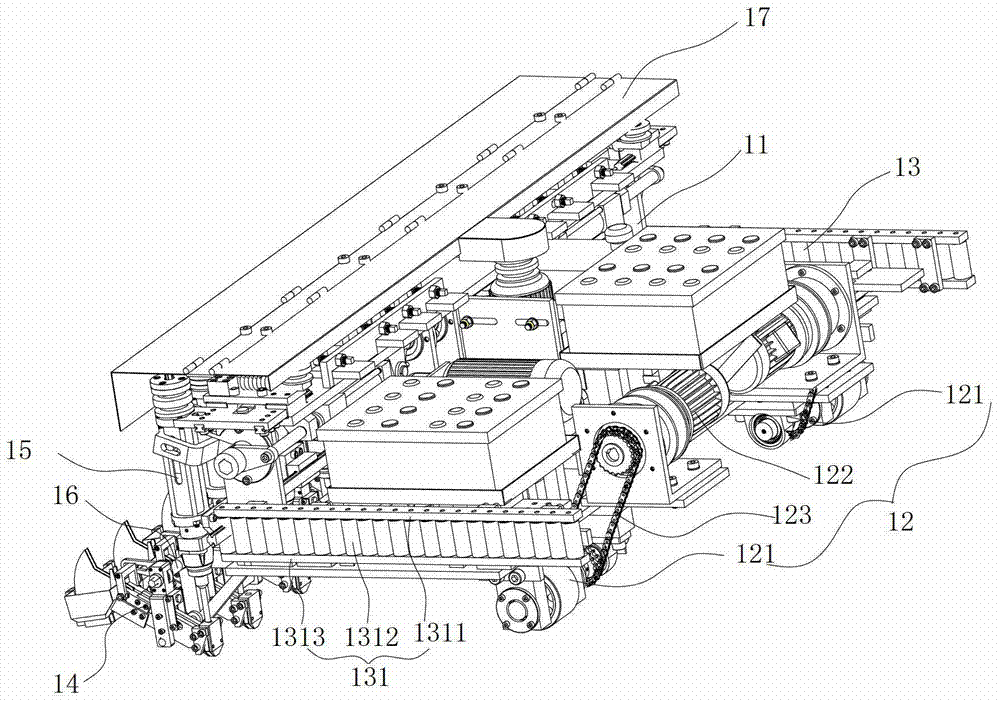

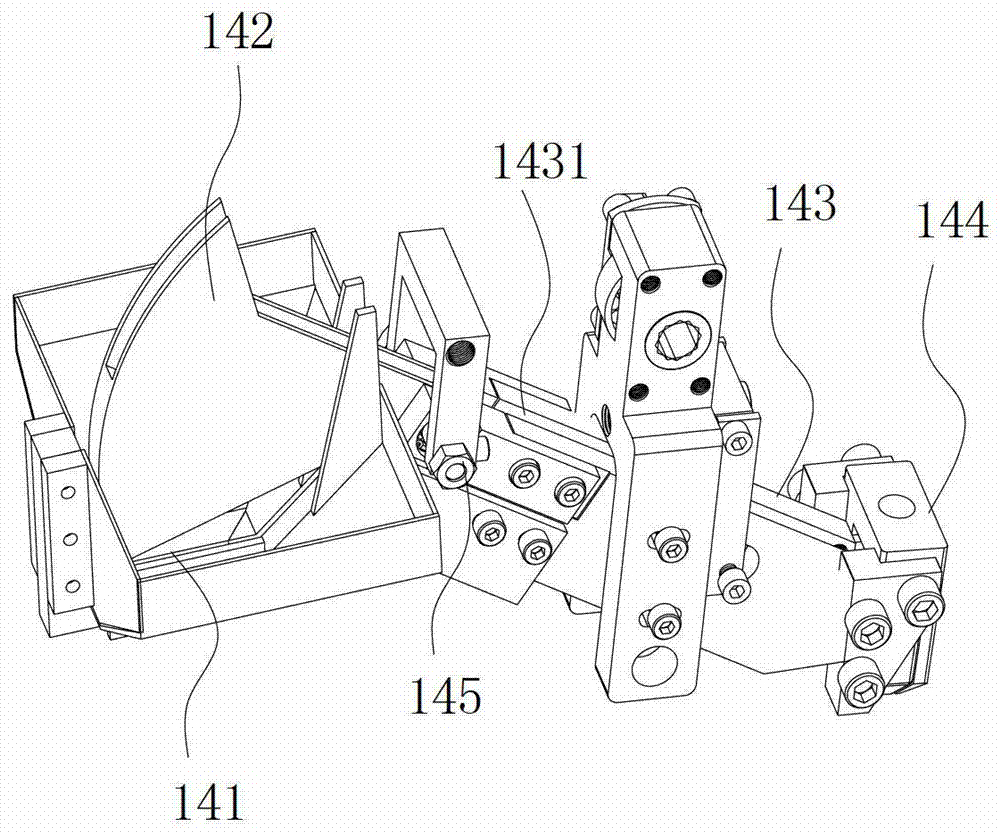

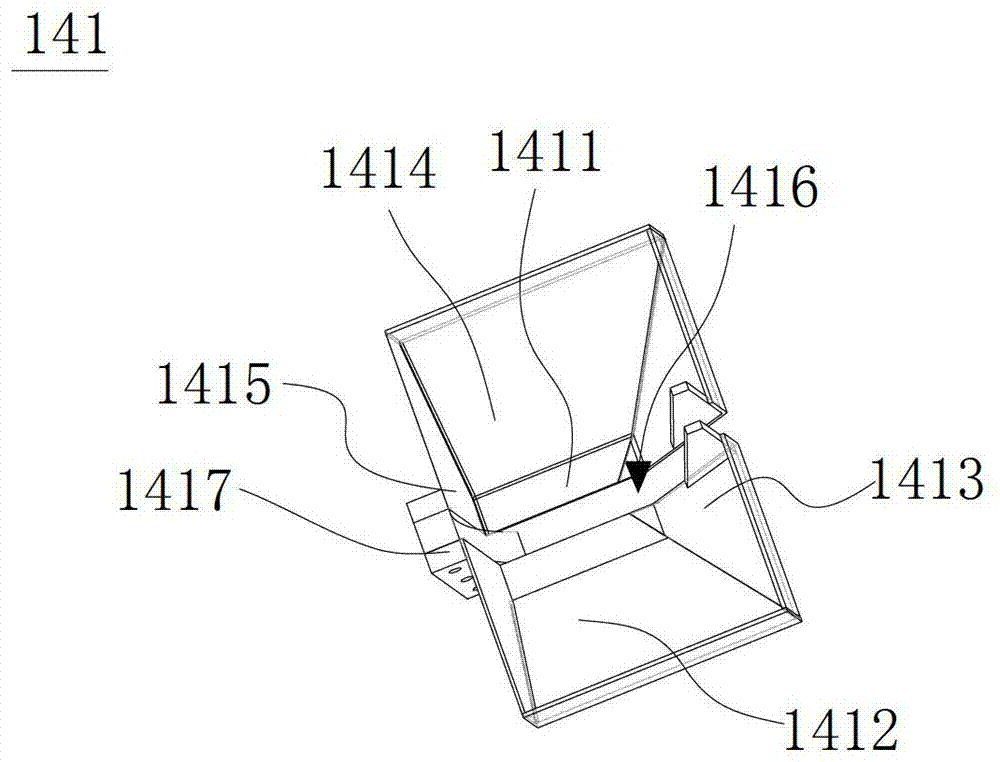

[0049] like figure 1 As shown, it is a schematic diagram of the structure of the automatic pendulum thread tightening machine of the present invention. Before describing the present invention in detail, the left side in the figure is defined as the front end of the automatic pendulum thread tightening machine, and the right side is defined as the rear end of the automatic pe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com