Single-sided concave-convex jacquard velvet fabric and weaving method thereof

A fabric and velvet technology, applied in the direction of digging fabrics, fabrics, multi-strand fabrics, etc., to achieve the effect of easy operation, smooth and clean fleece back, and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] (Example 1, single-sided two-color concave-convex jacquard velvet fabric)

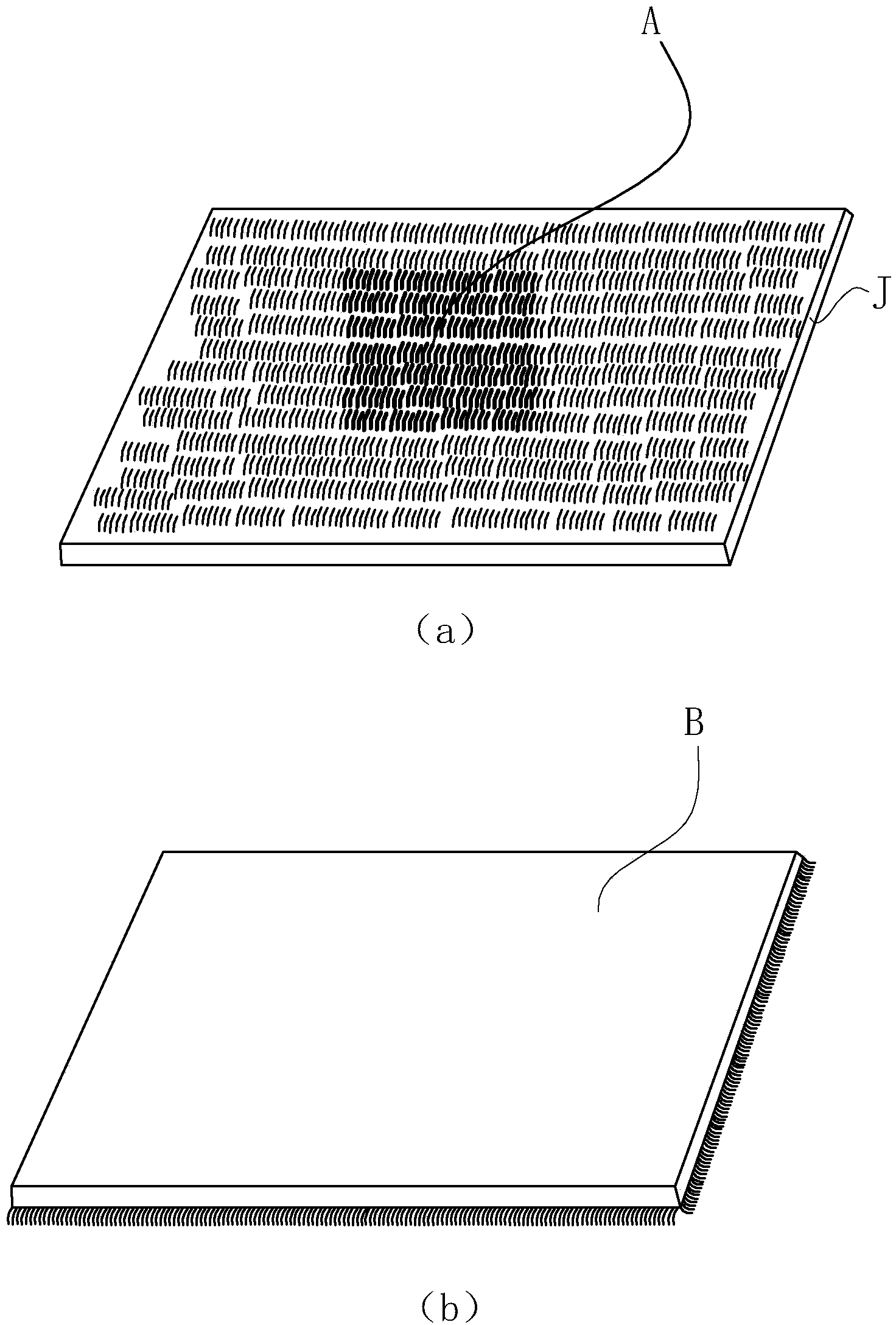

[0054] See figure 1 , One side of the base cloth J of the single-sided two-color concave-convex jacquard velvet fabric of this embodiment is the suede A, and the piles of two different colors are consolidated on the base cloth J; the other side is the fleece back, flat and without piles. The piles of two different colors on the suede A form a pattern, and the lengths of the piles are the same.

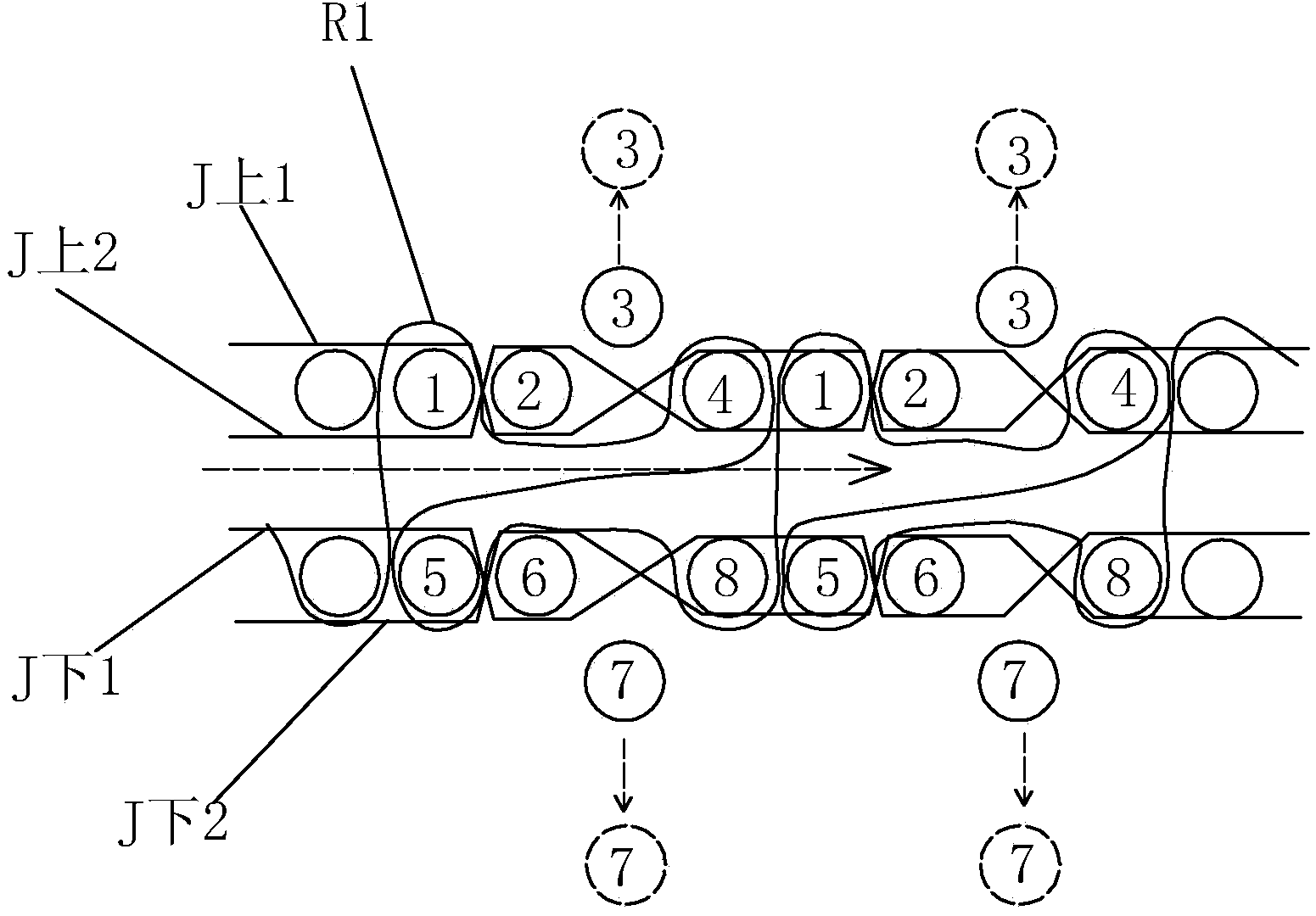

[0055] The single-sided two-color concave-convex jacquard velvet fabric includes ground warp yarns, weft yarns, auxiliary weft yarns and pile warp yarns; wherein the auxiliary weft yarns include upper layer auxiliary weft yarns 3 and lower layer auxiliary weft yarns 7 . The auxiliary weft yarns do not interweave with the ground warp yarns.

[0056] The ground warp of the upper base fabric is divided into the first ground warp J 上1 and second ground warp J 上2 The weft yarns include the first weft yarn...

Embodiment 2

[0080] (Example 2 Single-sided single-color concave-convex jacquard velvet fabric)

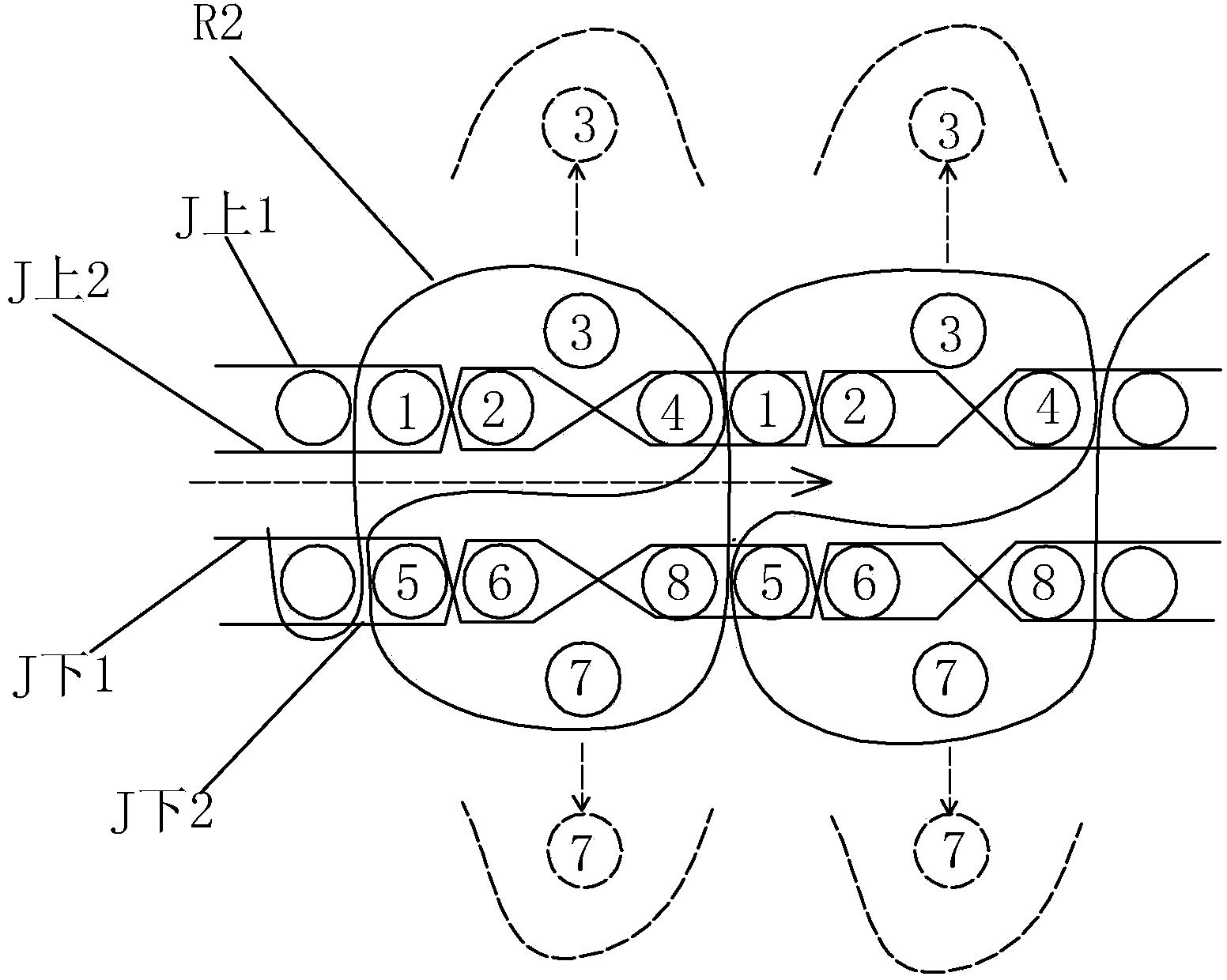

[0081] One side of the base fabric J of the single-sided single-color concave-convex jacquard velvet fabric of this embodiment is the suede A, and the piles of one color are consolidated on the base fabric J; the other side is the suede back, flat and without piles. The piles of one color on suede A form a pattern, and the lengths of the piles are the same. The rest of the fabric structure of the single-sided single-color concave-convex jacquard velvet fabric is the same as that of Embodiment 1, except that the single-sided two-color concave-convex jacquard velvet fabric is composed of two reed teeth in the warp and weft direction, ten warp yarns and eight weft yarns. A kind of cashmere warp threaded in a reed tooth R 1 and B cashmere warp yarn R 2 of the same color.

[0082] The rest of the weaving method of the single-sided single-color concave-convex jacquard velvet fabric is the same as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com