Frameless centrifugal high-efficiency splash device

A splash device and centrifugal technology, which are applied in the field of centrifugal high-efficiency splash devices, can solve the problems affecting the subdivision and uniformity of water droplets in the splash radius of water flow, and affect the cooling effect, etc., so as to improve the splash performance and improve the cooling effect. , the effect of product performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

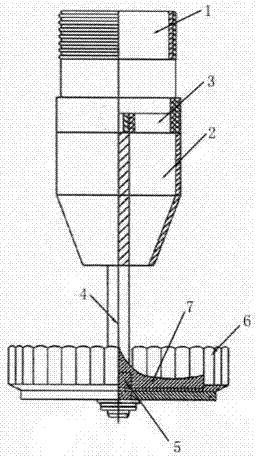

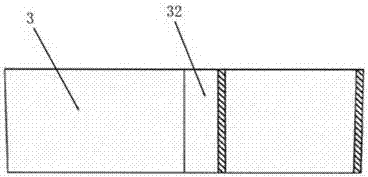

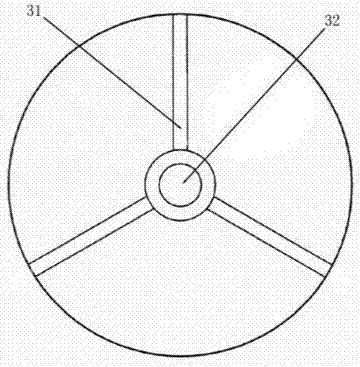

[0014] See Figure 1 to Figure 5 , the present invention has a water inlet pipe 1, the upper part of the water inlet pipe 1 is provided with an external thread connected with the water distribution pipe, the middle part is provided with a hexagonal nut 11 that is easy to tighten, and the lower part is provided with an external thread connected with the flow control pipe 2 ; The interior of the water inlet port 1 is a cone from the water inlet end to the water outlet end; the interior of the water outlet end of the water inlet port 1 is freely sleeved with a fixing bracket 3; the fixing bracket 3 is in the shape of a truncated cone Ring body, the interior of the fixed bracket 3 is separated into three channels by the support rib wall 31; the upper and lower ends of the main shaft 4 are provided with threads, and the joint part of the thread and the shaft body is provided with steps; the center of the fixed bracket 3 An axial threaded hole 32 is provided at the position, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com