Mounting structure for special-shaped motor

A technology of mounting structure and motor mounting plate, applied in the direction of electromechanical devices, electrical components, electrical components, etc., can solve the problem of large error of positioning ribs, and achieve the effects of firm positioning, improved coaxiality, and convenient disassembly and assembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings.

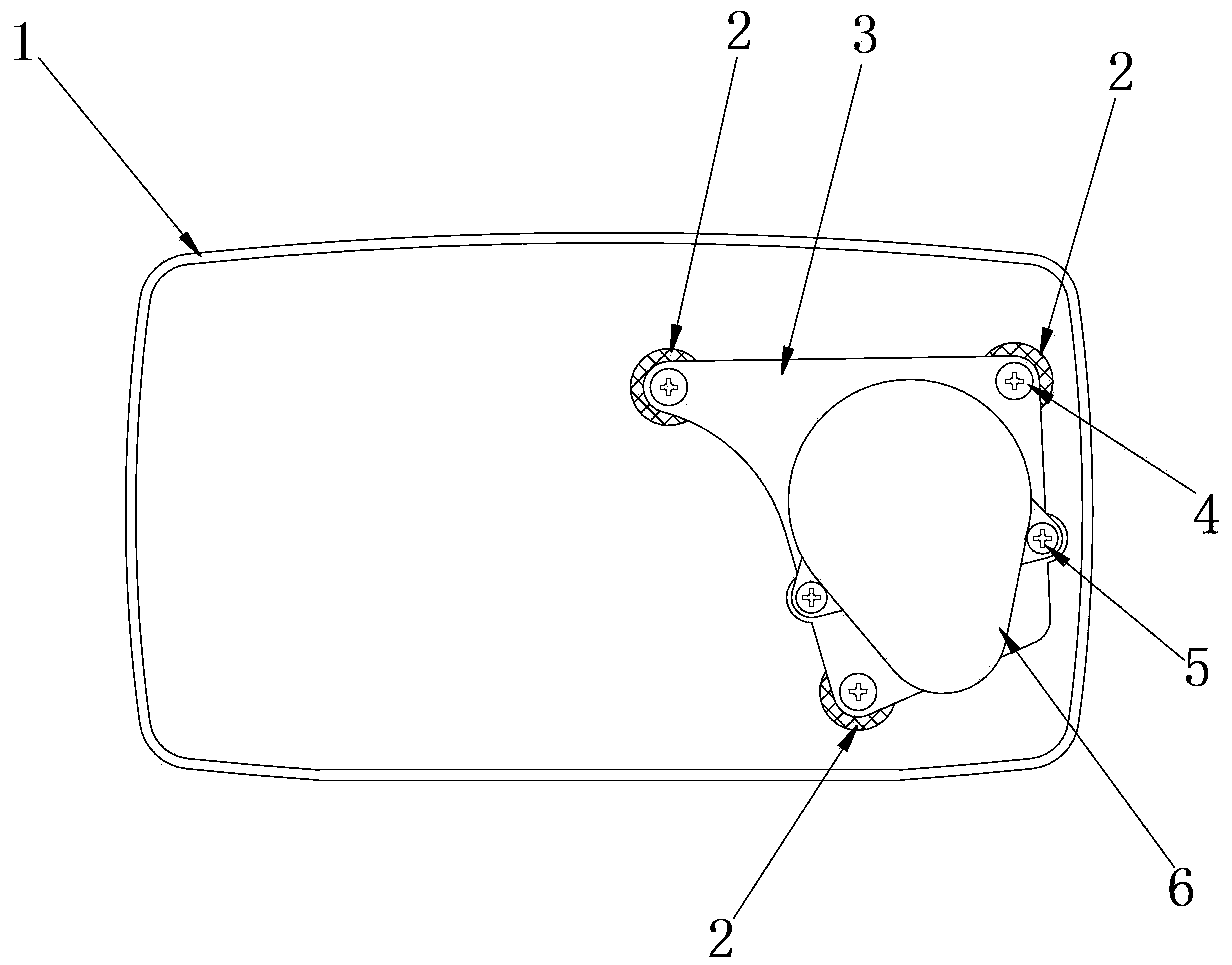

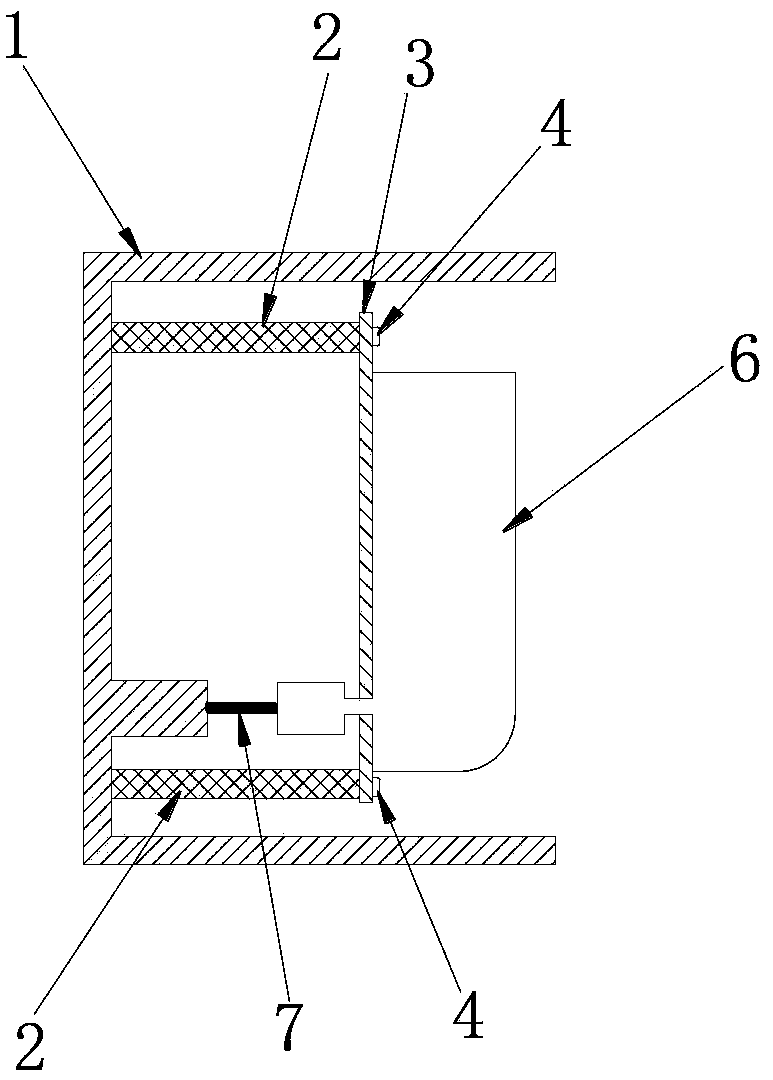

[0012] A mounting structure for a special-shaped motor, comprising a motor mounting plate 3, a large panel 1 and a special-shaped motor 6, the large panel 1 is fixed, a number of columns 2 are arranged on the large panel 1, and the motor mounting plate 3 passes through a The three screws 4 on the straight line are fixed on the corresponding column 2, and the three points are positioned firmly; the peripheral side of the special-shaped motor 6 is provided with two lugs on the left and right, and the motor screws 5 are arranged in the lugs. The motor 6 is fixed on the motor mounting plate 3 through lugs and motor screws 5 to achieve radial positioning. The output shaft of the special-shaped motor 6 passes through the motor mounting plate 3, and a pinion is installed on the output shaft, and a rolling pin 7 with an interference fit is provided in the center hole of the pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com