Artificial hand

A prosthetic hand and finger technology, which is applied in the field of prosthetic hands, can solve the problems of less movement of fingers to grasp objects, failure to ensure good signal, and heavy quality of prosthetic hands, etc., to achieve large grip, improve commercialization potential, and low processing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

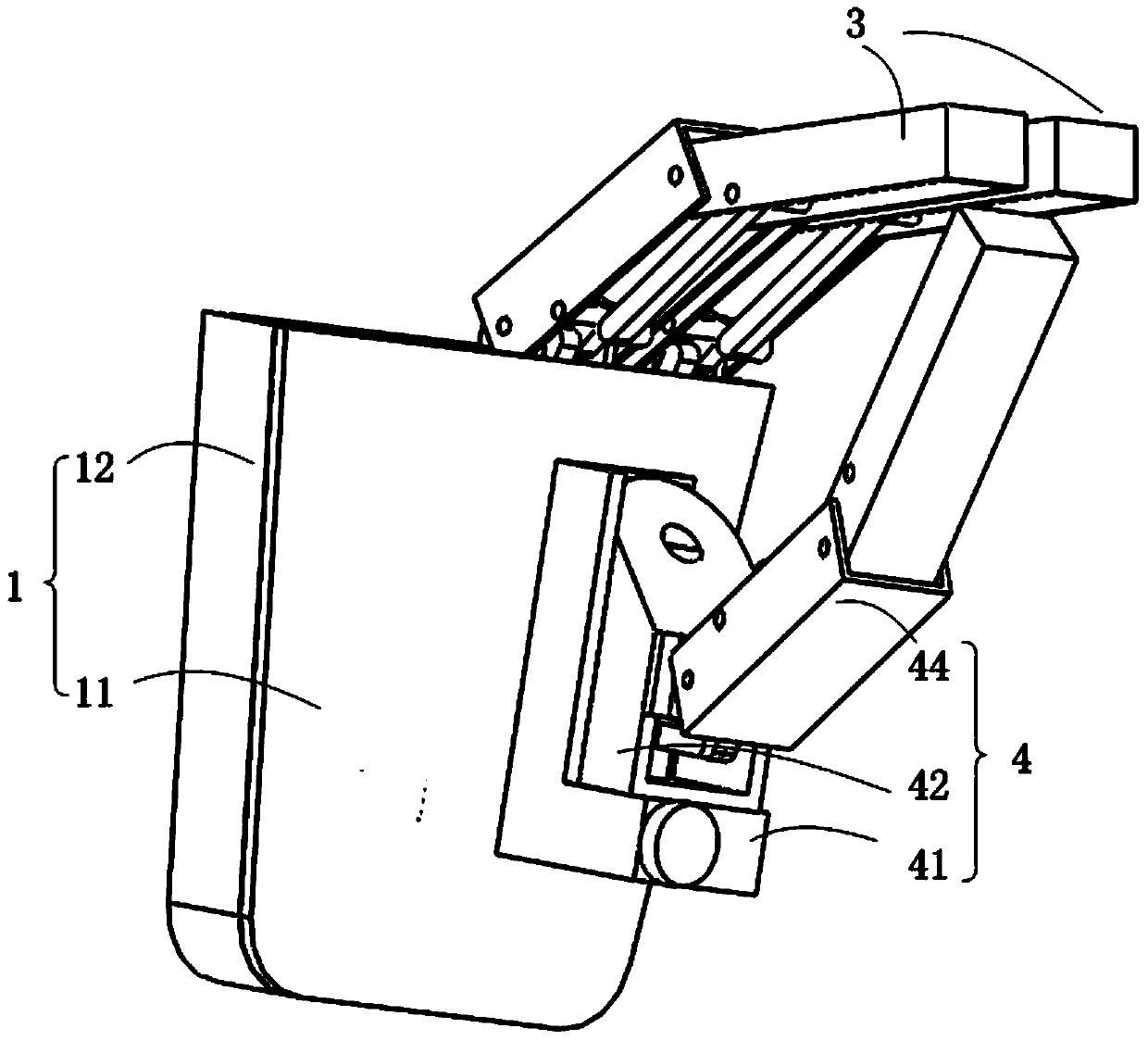

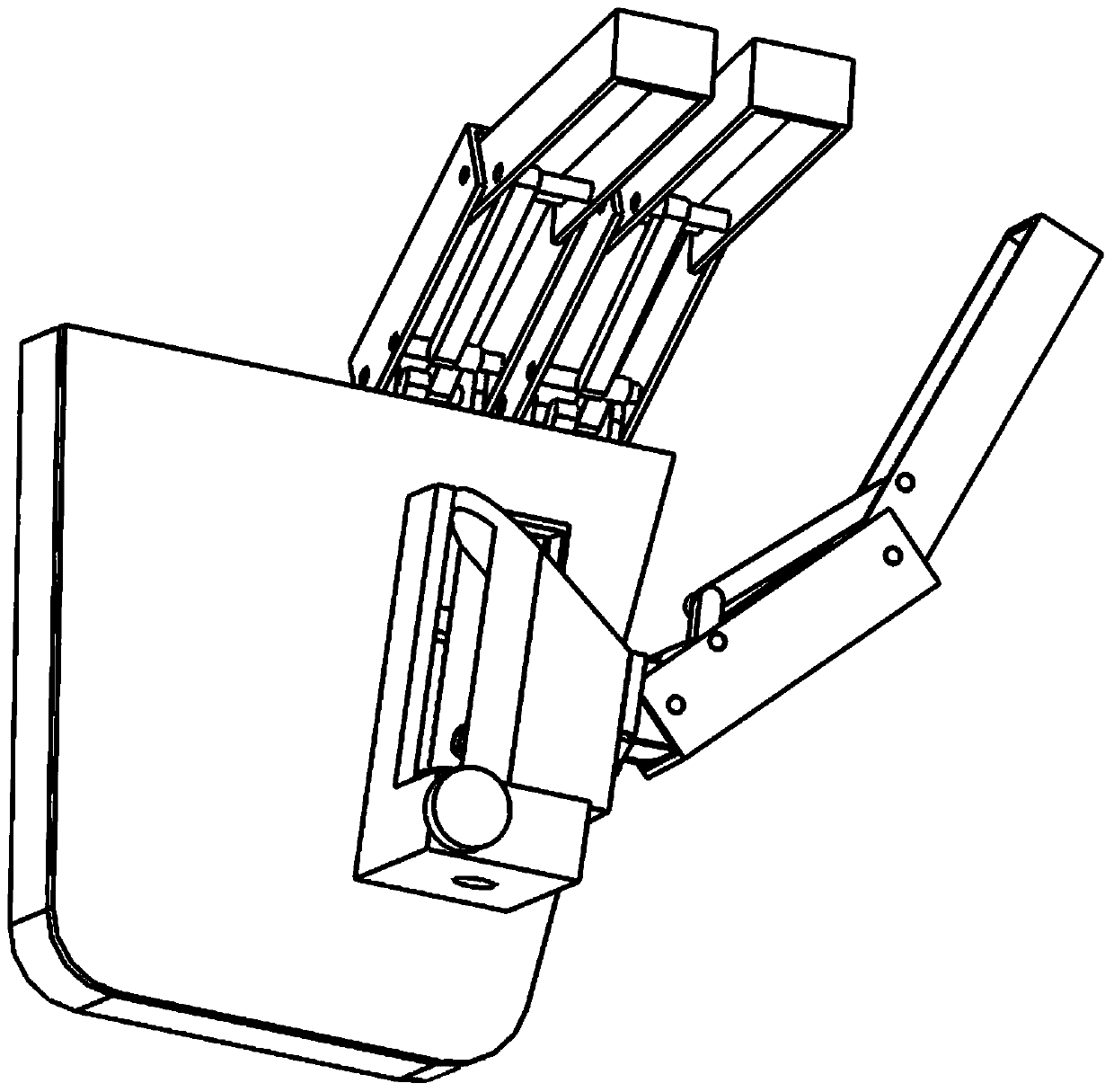

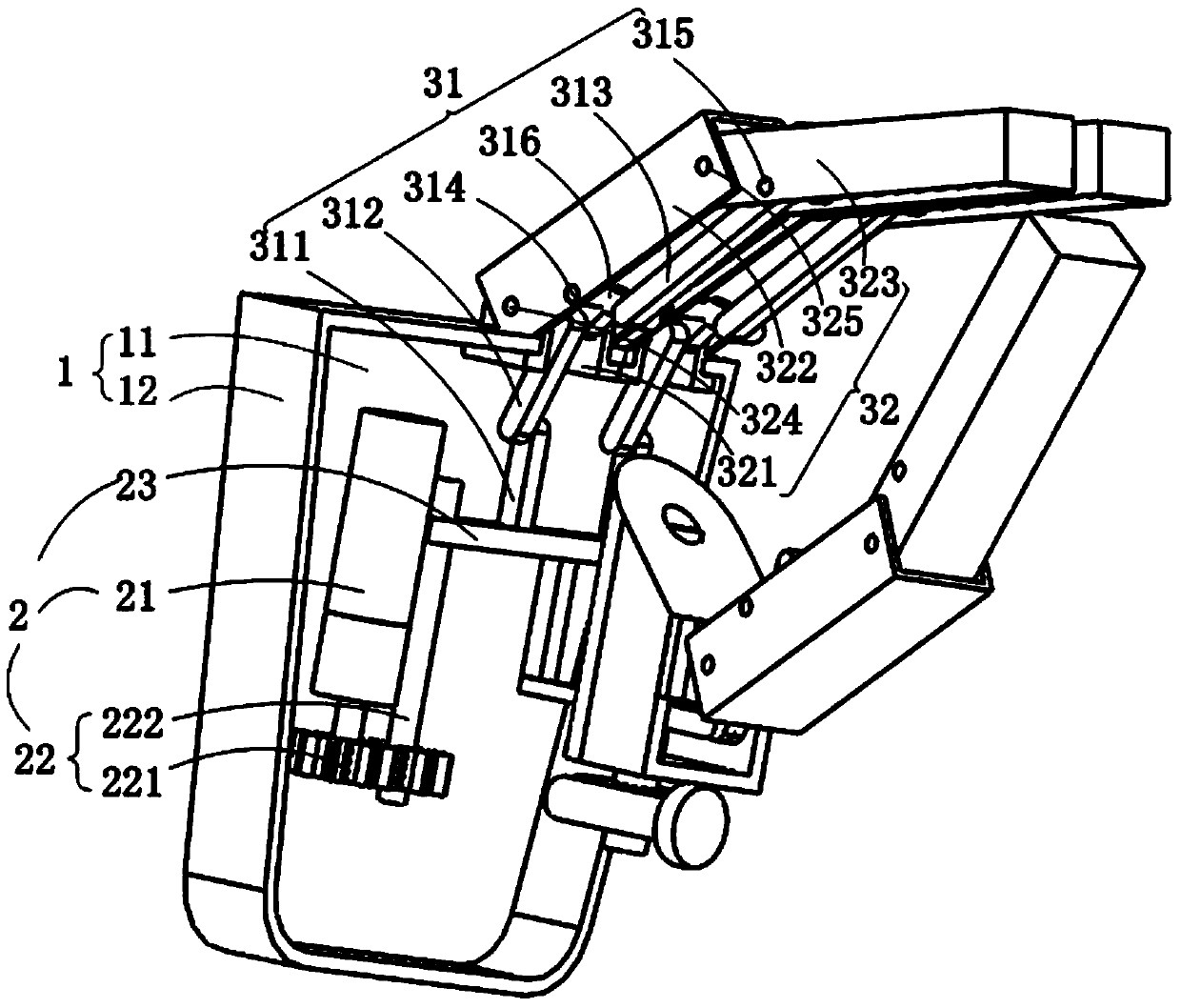

[0060] refer to figure 1 Referring to FIG. 6 , this embodiment provides a prosthetic hand, including a palm body 1 , a driving unit 2 , a finger unit 3 and a thumb unit 4 .

[0061] Such as figure 1 As shown, the palm body 1 includes two opposite palm covers 11 and a side cover 12 connecting the two palm covers 11 . The palm body 1 is a cavity enclosed by the two palm covers 11 and the side covers 12 .

[0062] Such as image 3 As shown, the drive unit 2 is arranged in the palm body 1 and includes a drive motor 21, a transmission mechanism 22 and a drive plate 23. The two ends of the transmission mechanism 22 are respectively connected to the drive motor 21 and the drive plate 23. The motor, that is, the drive motor 21 is actually a geared motor 21 .

[0063] The geared motor 21 is vertically arranged in the palm body 1, and the geared motor 21 is an improved motor integrated with a motor and a reducer. Adopting this motor can make the overall structure of the prosthetic ha...

Embodiment 2

[0092] Such as Figure 7 As shown, the difference between this embodiment and Embodiment 1 is that in this embodiment, the finger transmission mechanism 31 also includes a fourth finger transmission rod 317 and a fifth finger connecting piece 318, and the finger structure 32 also includes a third finger knuckle 326. The sixth finger connector 327;

[0093] One end of the fourth finger transmission rod 317 is connected with the third finger transmission rod 313, and the other end is connected with the third finger knuckle 326 through the fifth finger connector 318, and the third finger knuckle 326 is connected with the second finger connector 327 through the sixth finger connector 327. Finger knuckles 323 are connected.

Embodiment 3

[0095] The difference between this embodiment and Embodiment 1 is that the geared motor in this embodiment is arranged horizontally, and no synchronous gear is included in the drive mechanism of the drive unit. The drive unit includes a geared motor, a screw and a drive plate. The two ends of the rod are respectively connected to the geared motor and the driving board.

[0096] When the geared motor works, the geared motor drives the screw to move, and then the screw drives the drive plate to move.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com