Turbine high pressure inner cylinder thermometer hole machining location device and use method thereof

A technology of positioning device and temperature measuring hole, applied in the field of positioning device for processing temperature measuring hole, can solve problems such as dislocation, and achieve the effect of low manufacturing cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

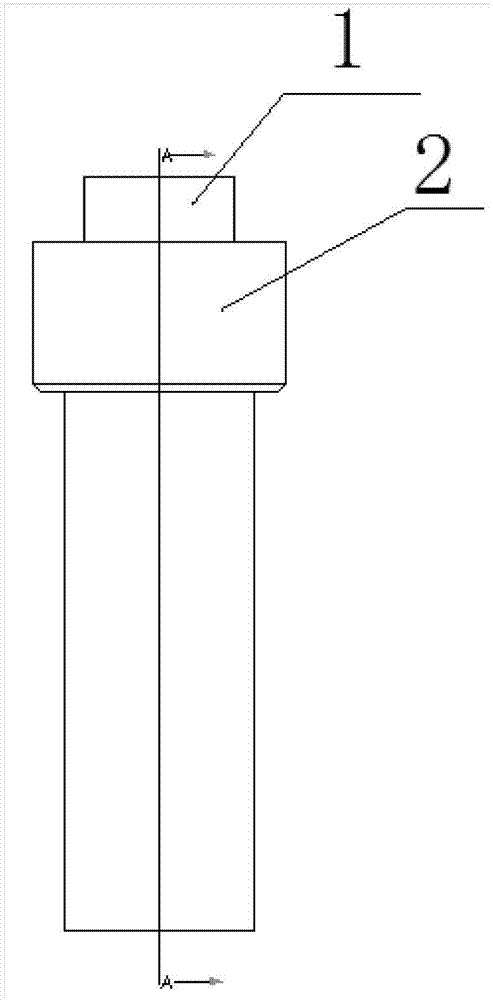

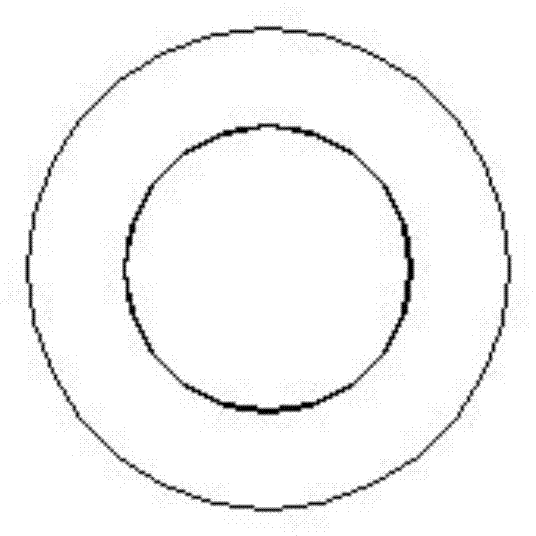

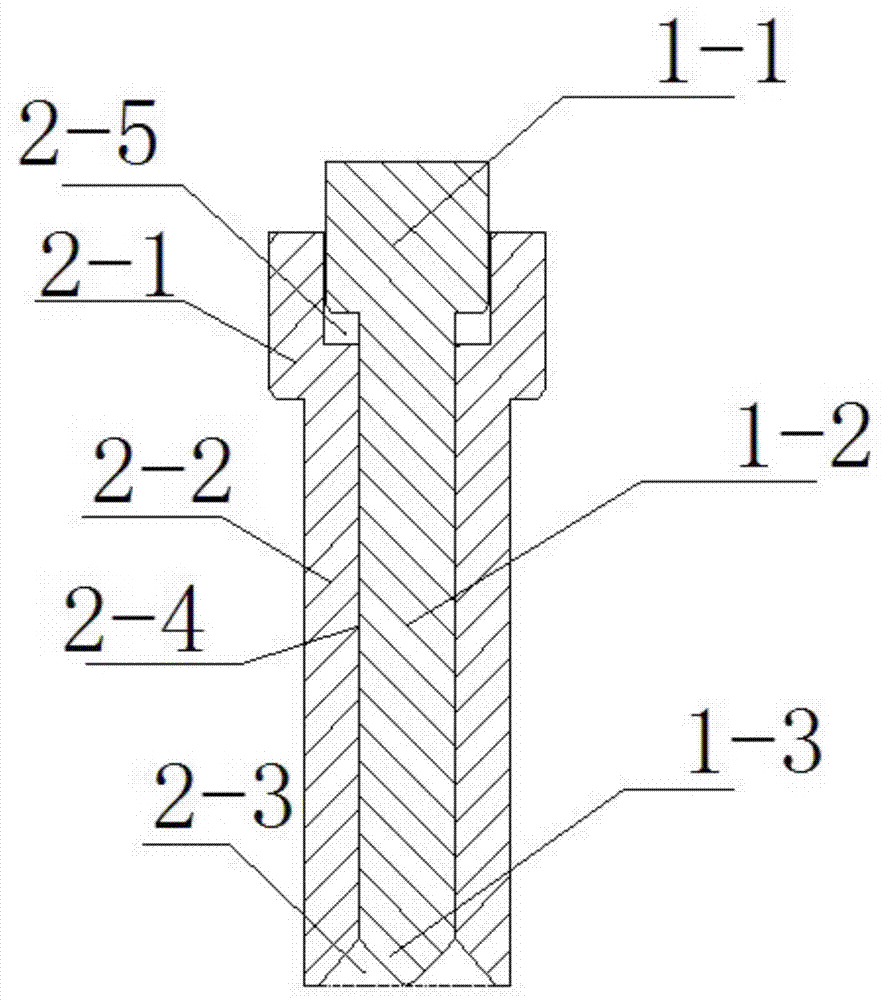

[0019] Specific Embodiment 1: A positioning device for machining the temperature measuring hole of the high-pressure inner cylinder of a steam turbine according to this embodiment is composed of a stepped shaft 1 and a reducing tube 2, wherein the stepped shaft 1 is divided into a cylinder 1 from top to bottom -1, three parts of cylinder 1-2 and cone 1-3, the reducing tube 2 is divided into three parts of flared tube 2-1, straight tube 2-2 and tapered hole tube 2-3 from top to bottom; The cylinder 1-2 has a smaller diameter than the cylinder 1-1.

specific Embodiment approach 2

[0020] Embodiment 2: This embodiment is the same as Embodiment 1 in that: the outer diameter of the straight pipe 2-2 is the same as the diameter of the through hole of the high-pressure outer cylinder 3 of the steam turbine. Others are the same as in the first embodiment.

[0021] The outer diameter of the straight pipe 2-2 and the diameter of the through hole of the high-pressure outer cylinder 3 are operated in cooperation with the shaft hole.

specific Embodiment approach 3

[0022] Specific embodiment three: a method for using a positioning device for processing a temperature measuring hole in a high-pressure inner cylinder of a steam turbine according to this embodiment is characterized in that it is carried out in accordance with the following steps:

[0023] 1. Assemble the high-pressure outer cylinder 3 and the high-pressure inner cylinder 4 of the steam turbine according to the position requirements in the assembly process;

[0024] 2. Paint the end face side of the tapered hole tube 2-3 for marking;

[0025] 3. Insert the reducing tube 2 into the through hole of the high-pressure outer cylinder 3 until the tapered hole tube 2-3 of the reducing tube 2 touches the temperature-measuring hole surface 5 of the high-pressure inner cylinder 4; then insert the stepped shaft 1. Insert it into the reducing tube 2 until the cone 1-3 of the stepped shaft 1 touches the surface 5 of the temperature measuring hole of the high-pressure inner cylinder 4;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com