Smashing and dedusting mechanism for rubber powder of waste tires

A technology of waste tire rubber and shredder, which is applied in the direction of dust removal, mechanical material recovery, combined device, etc. It can solve the problems of heavy dust, poor working environment, unfavorable physical and mental health of workers, etc., and achieve the effect of improving the workshop environment and reducing emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

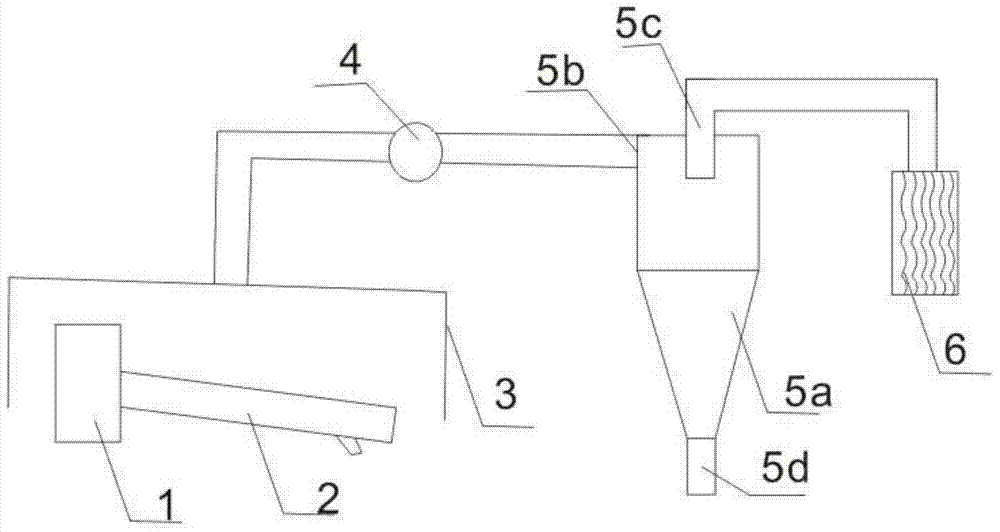

[0014] like figure 1 As shown, a waste tire rubber powder crushing and dedusting mechanism of the present invention is composed of rubber powder pulverizer 1, vibrating screen 2, dust collection cover 3, exhaust fan 4, cyclone dust collector, filter bag 6 and other components.

[0015] The rubber pulverizer 1 and the vibrating screen 2 are prior art, and the head of the vibrating screen 2 is located below the discharge port of the rubber pulverizer 1, and details are not repeated here.

[0016] The cyclone dust collector comprises a collector body 5a, the collector body 5a is composed of an upper cylinder section and a lower conical section, the upper end of the side wall of the collector body 5a is provided with a feed port 5b, and the top of the collector body 5a is provided with a row Air duct 5c, the bottom of exhaust duct 5c stretches in the collector body 5a, and the position of the lower end nozzle of exhaust duct 5c is lower than feed port 5b, avoids that air intake go...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com