Novel vehicle tire and production method thereof

A technology for tires and vehicles, which is applied to wheels, vehicle parts, spoke wheels, etc., and can solve problems such as inflation, easy tire burst, and easy puncture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

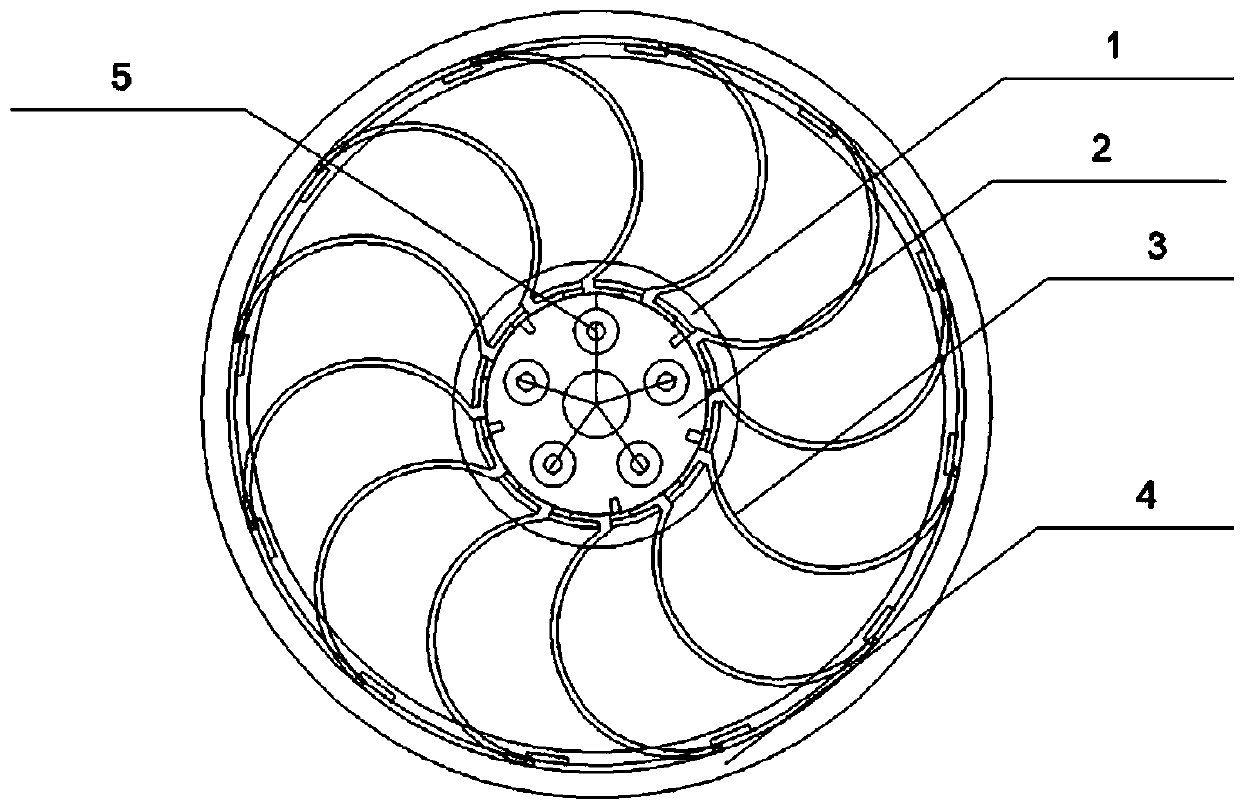

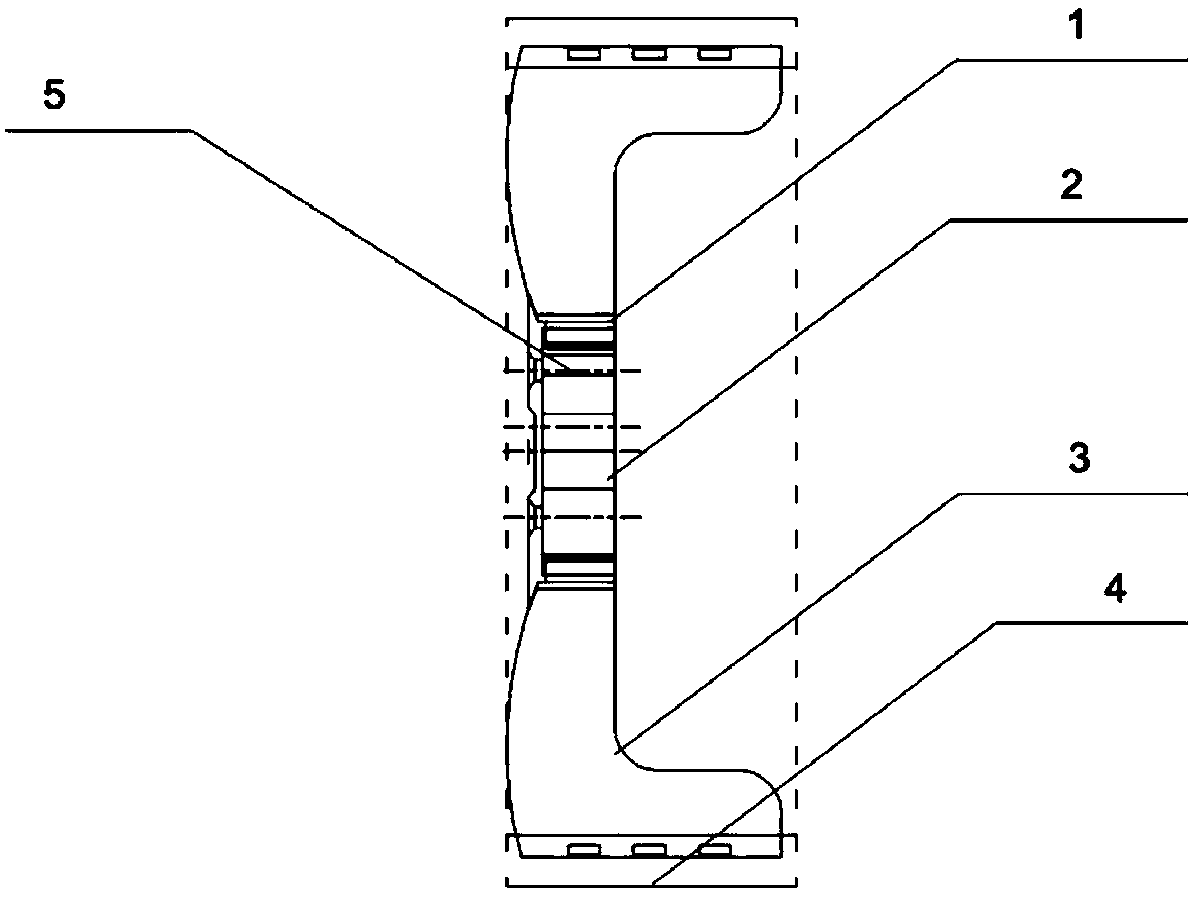

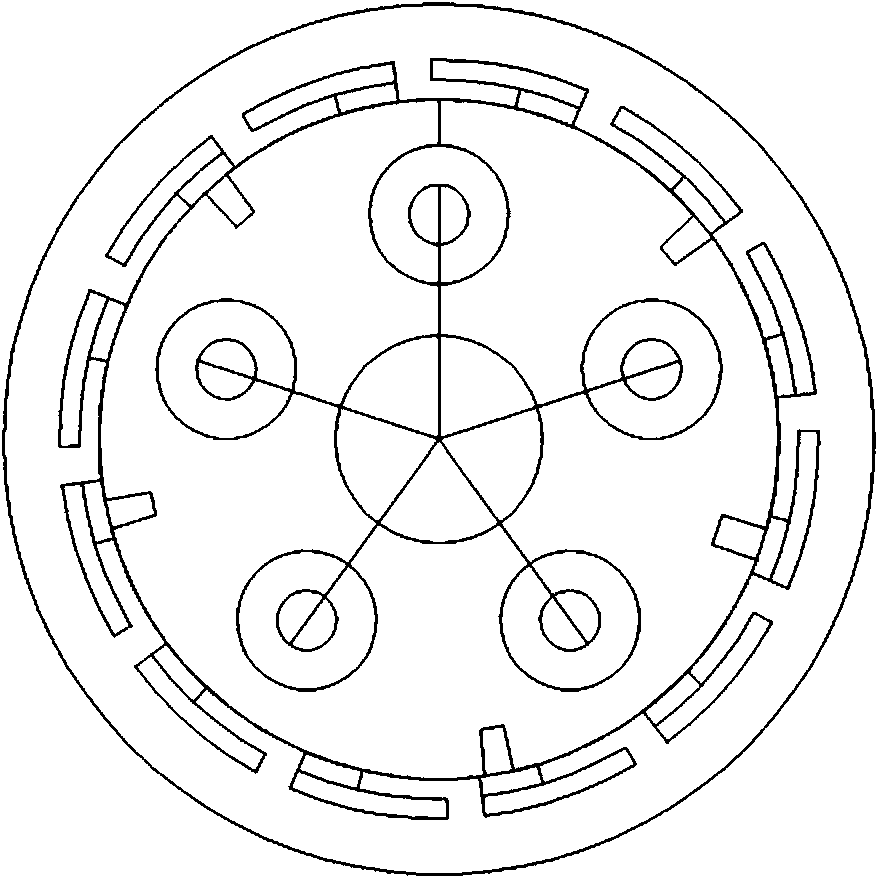

[0051] Please refer to Figure 1-2 , a new vehicle tire, including a middle ring (cage) 1, an inner ring 2, elastic spokes 3, rubber ring 4. The protruding part of the bottom of the elastic spoke 3 itself is inserted into the slot hole of the adjacent elastic spoke 3 to form a molded elastic spoke ring composed of the elastic spoke and the bottom of the elastic spoke. The upper end of each elastic spoke 3 is embedded in the mosaic groove of the middle ring (cage) 1, and the elastic spokes 3 are welded, riveted or screwed to the middle ring (cage) 1, so as to form the internal foundation of a tire. After rectification and appearance treatment, the apron 4 is covered and filled to form an integral tire shell. Embed the inner ring 2 into the inner mold cavity composed of the middle ring (cage) 1 and the elastic spokes 3 of the overall ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com