High-adaptation truss temperature control method

An adaptable and truss technology, applied in the aerospace field, can solve problems such as inability to adapt to temperature control requirements, and achieve the effects of flexible design, low cost, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the above objects, features and advantages of the present invention more comprehensible, specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0029] A highly adaptable truss temperature control method, comprising the following steps:

[0030] Step 1: coating the surface of the struts of the truss with multi-layer heat insulation components;

[0031] Step 2: Spray the smart coating on the remaining surfaces of the rod hinge that do not interfere with the unfolding of the moving parts.

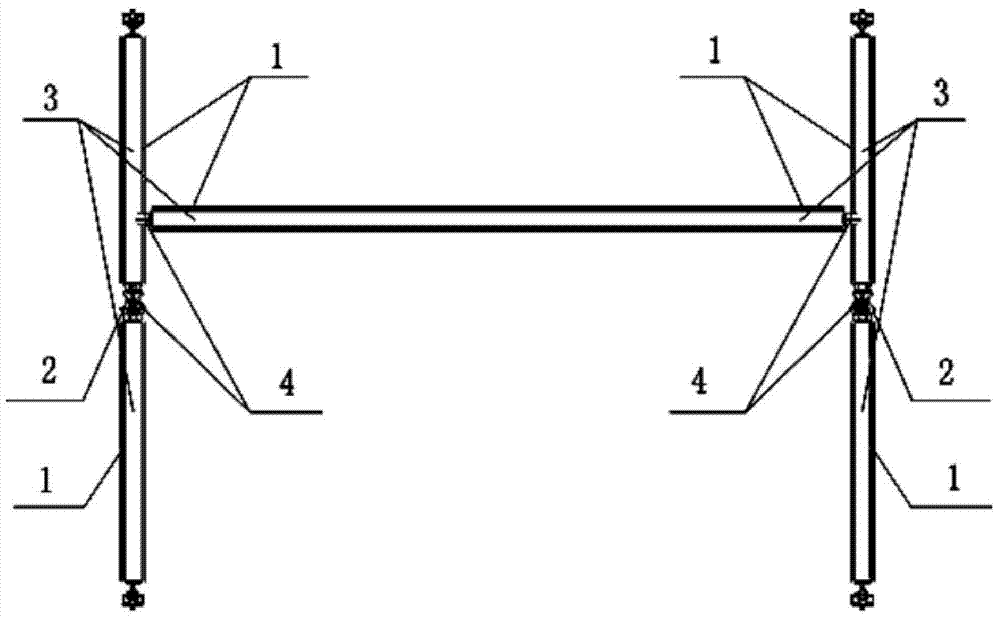

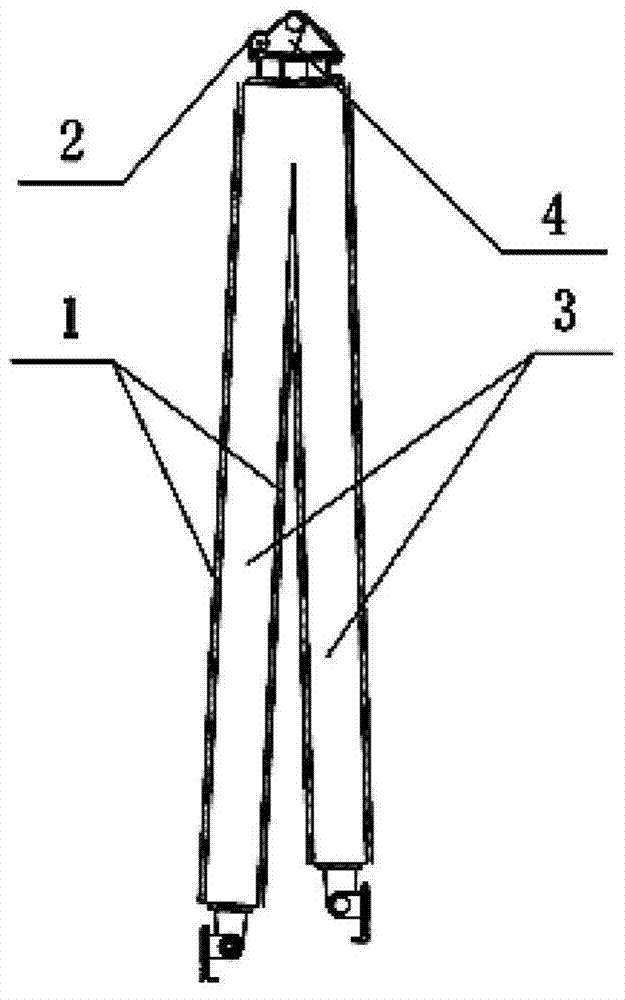

[0032] Specifically, the temperature control truss includes: multiple struts, multiple hinges, multi-layer heat insulation structure and intelligent coating, each strut is connected by a rod hinge, and the multi-layer heat insulation structure is covered on each strut Surface, smart coating is sprayed on the surface of the rod hinge.

[0033] Further, the multi-layer heat insulation structure in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com