A truss-type foldable unit driven by an elastic hinge and a foldable support arm

An elastic hinge and truss-type technology, applied in the direction of motor vehicles, space navigation equipment, space navigation aircraft, etc., can solve the problems of low repeated deployment accuracy, complex driving mechanism, low deployment reliability, etc., and achieve the purpose of strengthening the overall rigidity and The effect of repeatable unfolding accuracy, simple unfolding control, and smooth implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

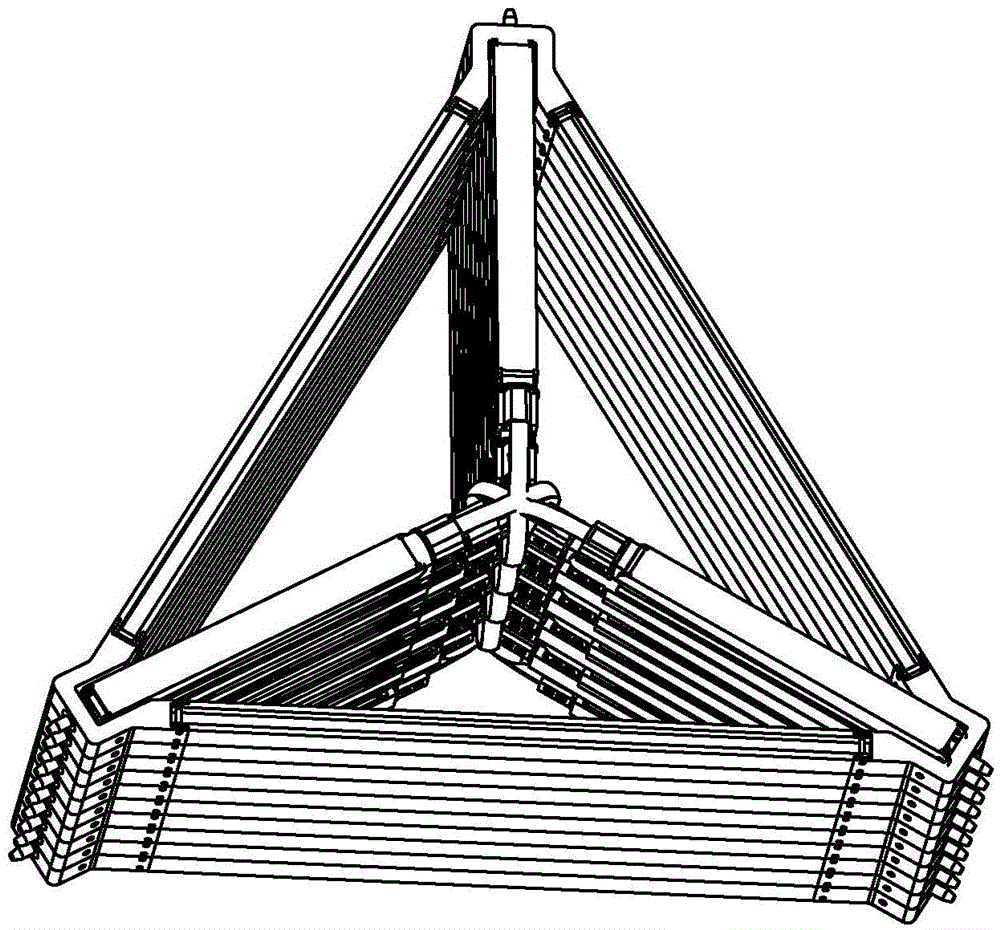

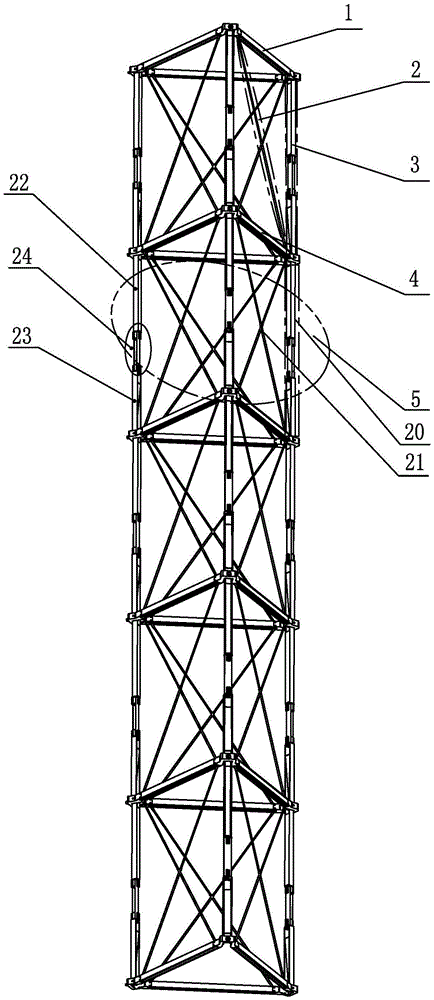

[0013] Specific implementation mode one: combine Figure 1-Figure 10 Explain that a truss-type foldable unit driven by elastic hinges in this embodiment includes an upper frame 1, a lower frame 4, N elastic hinged folding arms 3 and N sets of cable assemblies 2; the upper frame 1 and The lower frame 4 is an N-sided frame;

[0014] The upper frame 1 and the lower frame 4 are set in parallel, and the N vertices of the upper frame 1 and the N vertices of the lower frame 4 are set up and down correspondingly, and each vertex corresponding to the upper frame 1 and the lower frame 4 is passed through an elastic The hinged folding arms 3 are supported and rotatably connected, and a group of cable assemblies 2 are arranged at the diagonals of the rectangular plane formed between the upper frame 1, the lower frame 4 and two adjacent elastic hinged folding arms 3, wherein N is a positive integer, and 3≤N≤6.

[0015] The truss-type foldable unit driven by the elastic hinge of this embo...

specific Embodiment approach 2

[0016] Specific implementation mode two: combination figure 1 and Figure 4 Note that the upper frame 1 and the lower frame 4 in this embodiment are both triangular or quadrilateral frames. With such arrangement, the structure is simple, the design is reasonable, and it is easy to use. Others are the same as in the first embodiment.

specific Embodiment approach 3

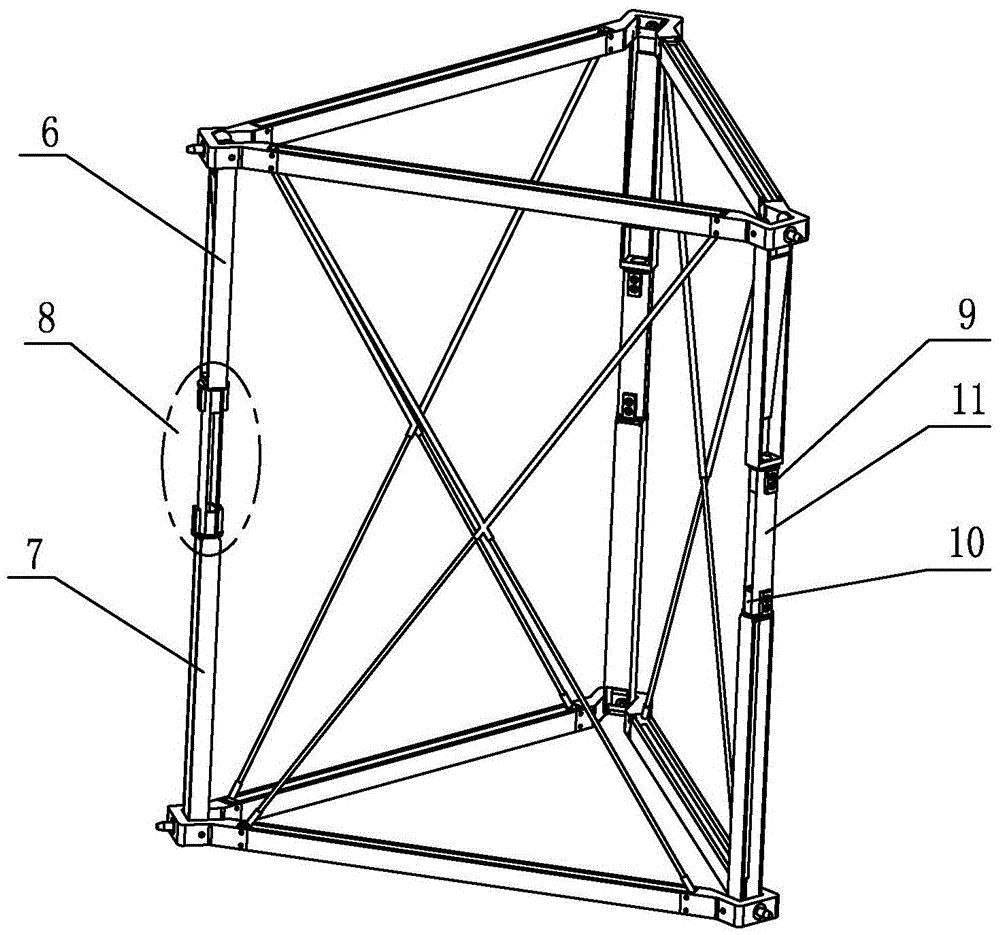

[0017] Specific implementation mode three: combination Figure 1-Figure 3 , Figure 5 , Figure 6 Explain that each elastic hinge type folding arm 3 in this embodiment includes a unit upper folding arm 6, a unit lower folding arm 7 and a unit connection elastic hinge assembly 8, and the unit connection elastic hinge assembly 8 includes two elastic hinge connections Joint 10, two elastic hinge spring pieces 11 and four elastic hinge connection pressing blocks 9, the adjacent ends of the unit upper folding arm 6 and the unit lower folding arm 7 are respectively affixed to the elastic hinge connection joint 10, and the two elastic hinge springs The sheets 11 are symmetrically distributed side by side, and the two ends of the two elastic hinge spring sheets 11 are respectively glued to the corresponding elastic hinge connection joints 10, and the four elastic hinge connection pressure blocks 9 are divided into two pairs arranged symmetrically up and down, and each elastic hinge ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com