A control system for electric hoist to automatically lift the trough

A technology of electric hoist and control system, which is applied in the direction of spring mechanism, winch device, etc., to achieve good economic effect, simple control system, and safe and reliable control method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to further explain the technical means and effects of the present invention to achieve the intended purpose of the invention, the following is a specific implementation of the control system for the electric hoist automatic jacking tank proposed by the present invention in conjunction with the accompanying drawings and preferred embodiments Mode, structure, feature and effect thereof are as follows in detail.

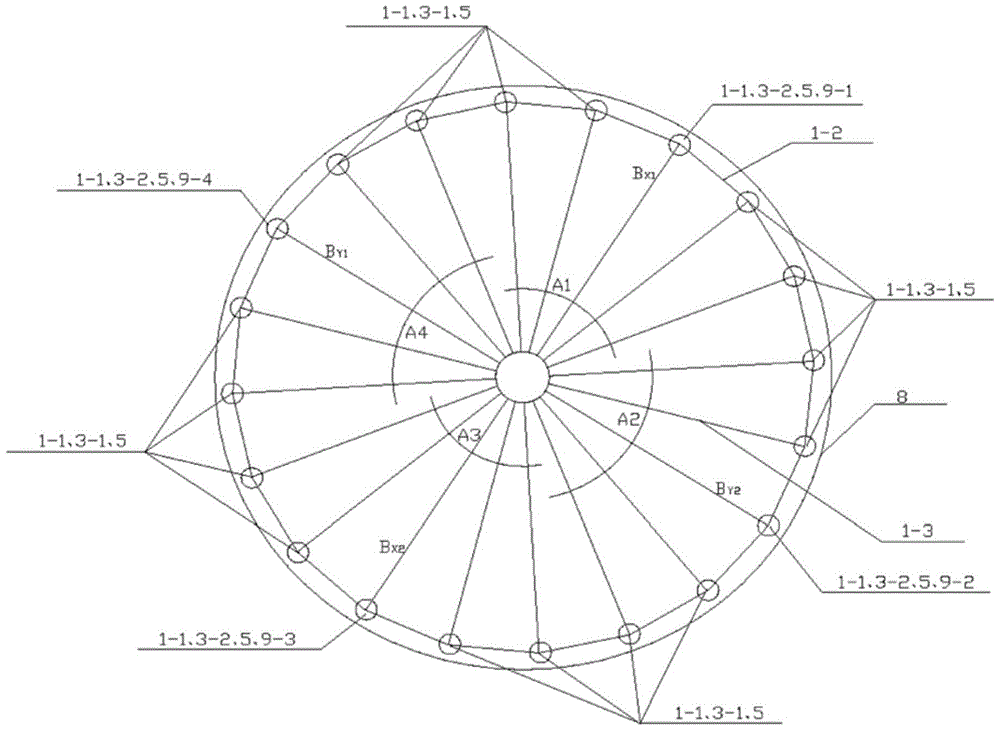

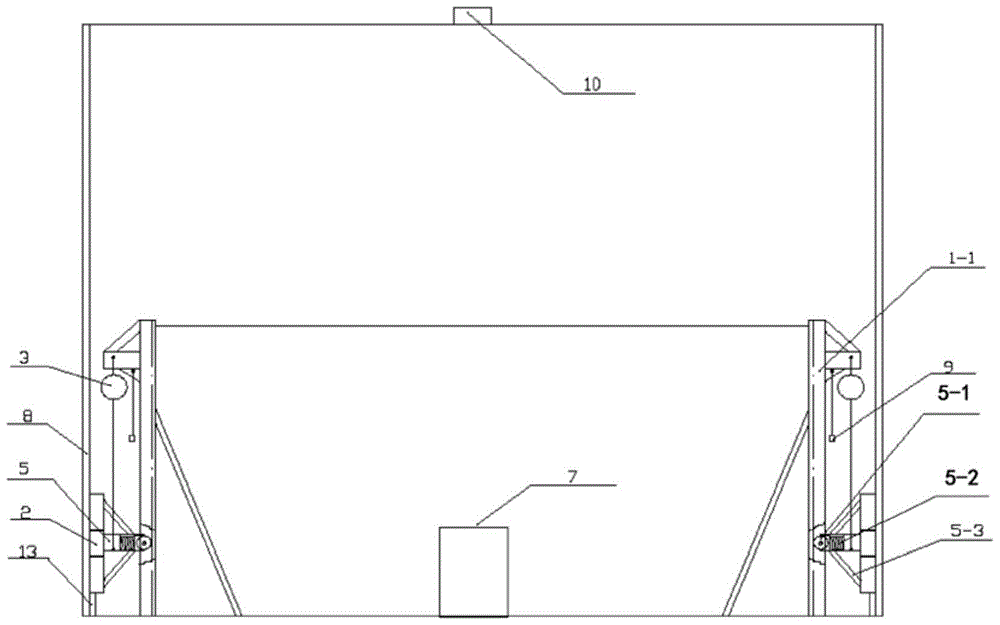

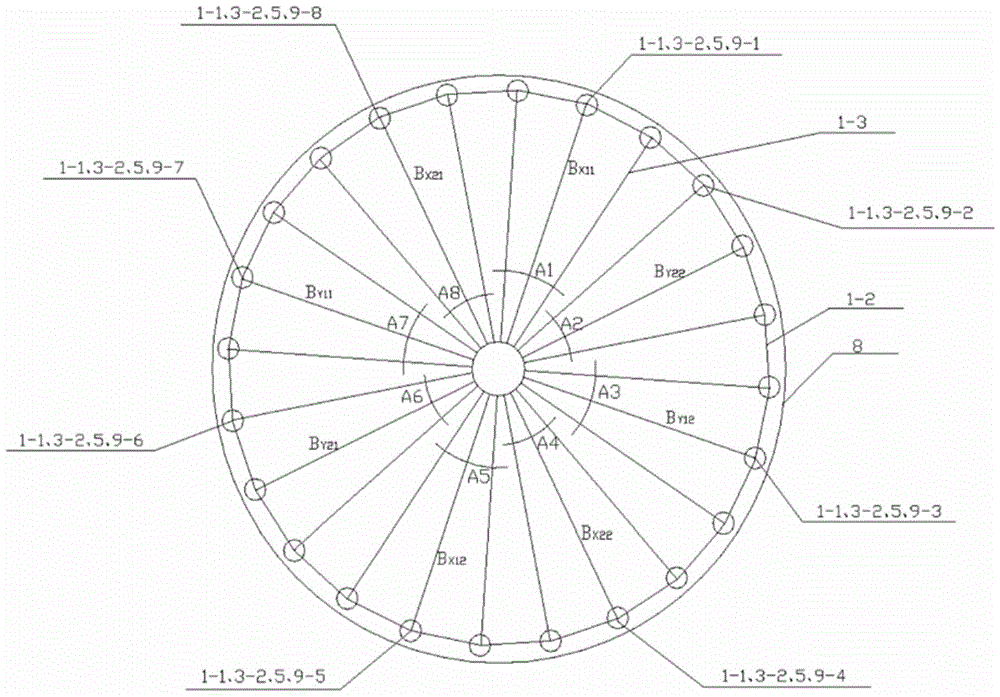

[0024] refer to figure 1 and figure 2 As shown, it is a top view and a sectional view of the control system of the electric hoist automatic jacking tank body of the embodiment of the present invention; refer to image 3 and Figure 4 As shown, it is a top view and a sectional view of a control system for an electric hoist automatic jacking trough according to another embodiment of the present invention; wherein the control system for an electric hoist automatic jacking trough includes n central supports 1 and expansion rings 2 , n sets of electric ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com