Online polyester production conversion equipment and production conversion method adopting same

A kind of equipment and polyester technology, which is applied in the field of polyester online conversion equipment and the use of this equipment for production conversion, can solve problems such as affecting the economic benefits of enterprises, and achieve the effect of quickly realizing online production conversion, reducing transition time, and reducing material volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

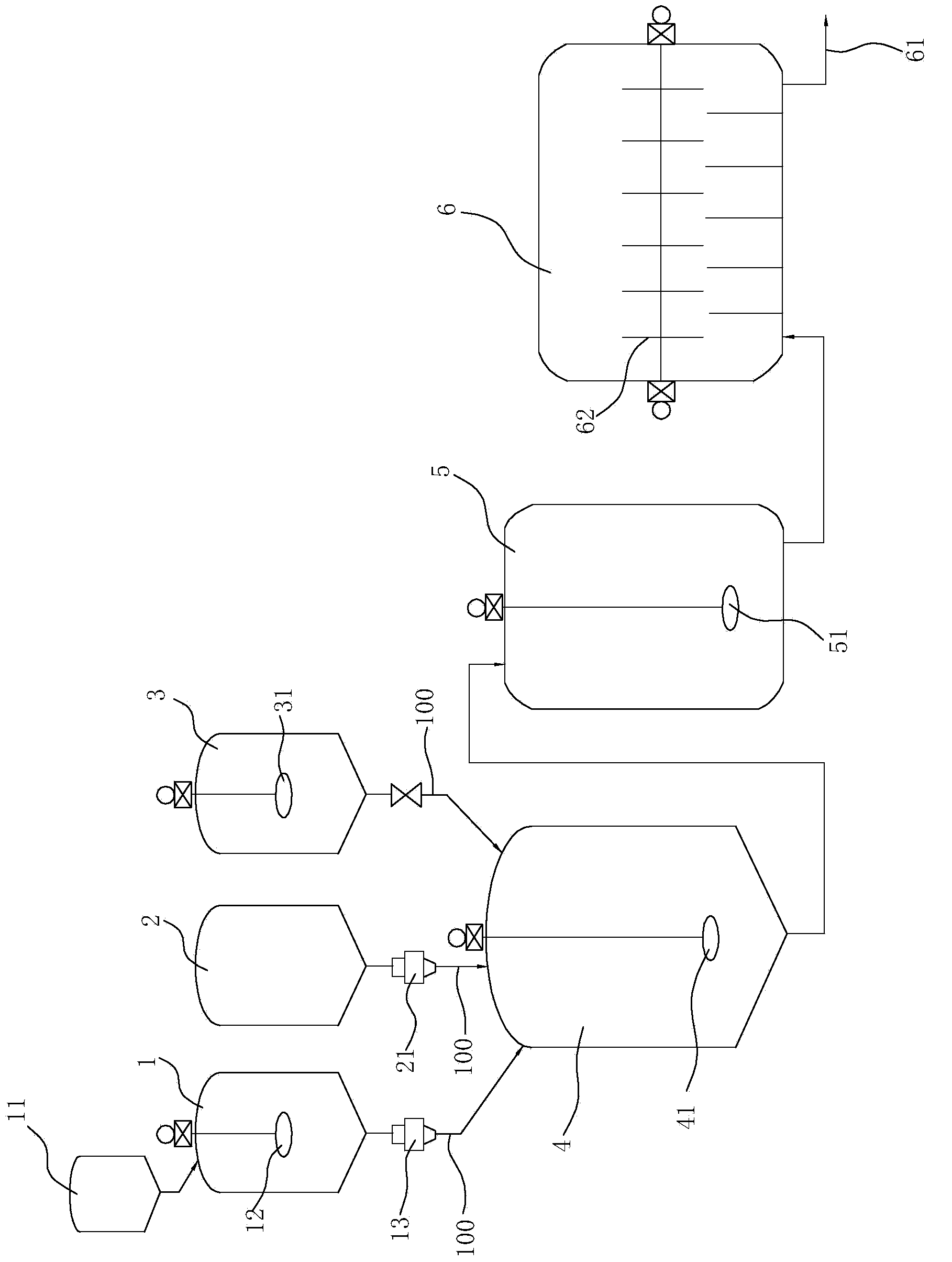

[0027] Such as figure 1 As shown, the online conversion equipment of the present embodiment includes an additive mixing tank 1, a phthalic acid feeding tank 2, an additive mixing tank 3, a polymerization mixing tank 4, an esterification kettle 5 and a polycondensation kettle 6, and the additive mixing tank 1 The volume is 10% to 100% of the volume of the polymerization mixing tank 4 . The feed port of the additive mixing tank 1 is connected with an additive feeding tank 11 and has a first agitator 12, and the discharge port has a first metering scale 13; the discharge port of the phthalic acid feeding tank 2 has a second metering scale 21 , there is a second agitator 31 in the additive configuration tank 3, the polycondensation kettle 6 has a discharge port 61 and a third agitator 62, the discharge end of the esterification kettle 5 is connected with the feed port of the polycondensation kettle 6 and has a fourth stirring device 51, the fifth agitator 41 is arranged in the po...

Embodiment 2

[0033] Use the on-line conversion equipment of embodiment 1 to change production process of isophthalic acid content from high to low, the on-line conversion method of the present embodiment comprises the following steps:

[0034] (1) Within 3 hours before changing production, configure 10 tons of mixed slurry through additive feeding tank 11 and additive mixing tank 1. By mass, the mixed slurry is isophthalic acid: terephthalic acid=6:4, stirred 5h;

[0035] (2) Turn on the conversion equipment, reduce the liquid level of the polymerization slurry tank 4 to 5% of the tank volume, and transport the mixed slurry configured in step (1) to the polymerization slurry tank 4 within 10 minutes, and simultaneously, respectively Supplement terephthalic acid and ethylene glycol through phthalic acid feeding tank 2 and additive configuration tank 3 in the polymerization slurry mixing tank 4, and the addition of terephthalic acid and ethylene glycol is consistent with before changing prod...

Embodiment 3

[0038] Using the on-line conversion equipment of embodiment 1 to change the production process of isophthalic acid content from low to high, the on-line conversion method of the present embodiment comprises the following steps:

[0039] (1) Within 8 hours before changing production, configure 18 tons of mixed slurry through additive feeding tank 11 and additive mixing tank 1. By mass, the mixed slurry is isophthalic acid: terephthalic acid=2:8, stirred 10h;

[0040] (2) Turn on the conversion equipment, reduce the liquid level of the polymerization mixing tank 4 to 10% of the volume of the tank body, transport the mixed slurry configured in step (1) to the polymerization mixing tank 4 within 45 minutes, and simultaneously, respectively Supplement terephthalic acid and ethylene glycol through phthalic acid feeding tank 2 and additive configuration tank 3 in the polymerization slurry mixing tank 4, and the addition of terephthalic acid and ethylene glycol is consistent with befo...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap