A kind of processing method of silica sol

A technology of silica sol and silica, which is applied in the direction of polishing compositions containing abrasives, etc., can solve the problems of limited resources, increased chemical reaction speed, large alumina particle size, etc., and achieves improved scope of application, simple steps, and high efficiency high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The content of silicon dioxide in ordinary silica sol is 20%, and the particle size is 20nm. The processing steps are as follows:

[0034] (1) Regenerate the strong acid type cation exchange resin and the strong base type anion exchange resin respectively;

[0035] (2) Mix the regenerated strong acid type cation exchange resin and the strong base type anion exchange resin in a volume ratio of 10:1 to obtain a strong acid and strong base mixed resin, and put it into a container with cooling, heating and stirring;

[0036] (3) Add ordinary silica sol into the container with strong acid and strong alkali mixed resin, control the temperature of silica sol to 30°C, and the weight ratio of strong acid and strong alkali mixed resin to silica sol is 1:30;

[0037] (4) Open the stirring device in the container, stir, make ordinary silica sol and strong acid and strong alkali mixed resin mix evenly;

[0038](5) In the process of step (4), add oxazole, the addition is 5% of the ...

Embodiment 2-7 and comparative example 1-2

[0041] Embodiments 2-7 and Comparative Examples 1-2 were carried out with reference to the steps of Embodiment 1, and the corresponding processing conditions were changed, as specifically listed in the table below.

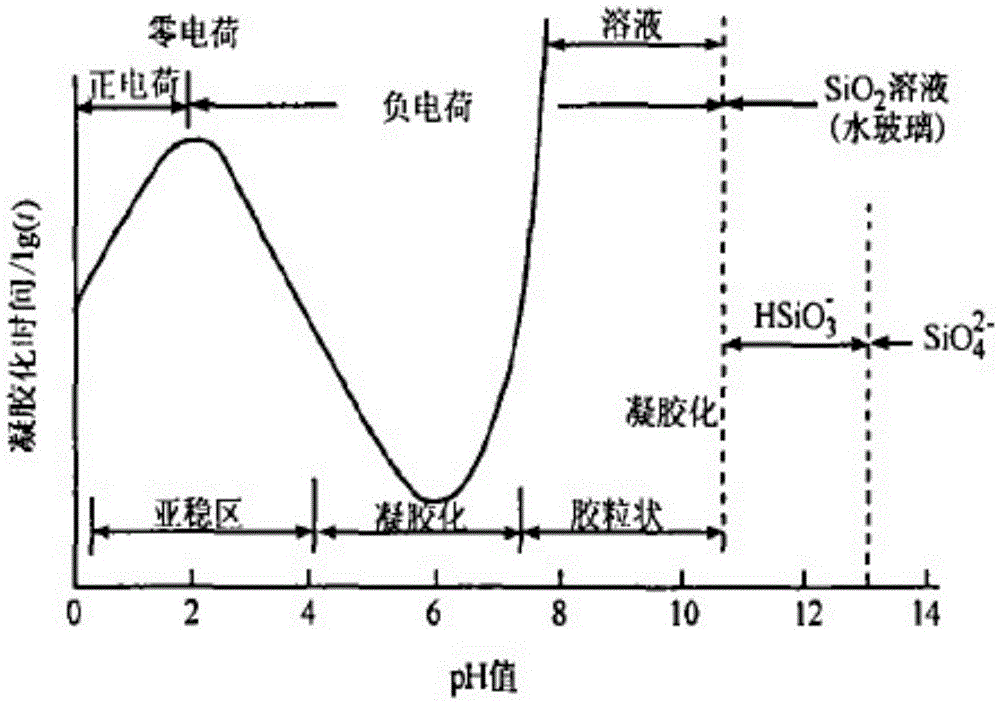

[0042] The common silica sol defined in the present invention refers to the silica sol having the following stability in different pH ranges. When the pH is 0-4, it is a metastable region. Silica sol can be stored in this state for a period of time. When the pH is 4-7, it is a gelation region. In this state, silica sol will gel and cannot be stored stably. When the temperature is 7-10.5, the silica sol still maintains the shape of colloidal particles and can be stored stably. Especially when the pH value is about 2 or 9, the gelation time is the longest, that is to say, the silica sol has a stable area in the acidic and alkaline areas, and can be stored stably in these two areas. The above are well-known and commonly used definition methods by those skilled in th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com