Method for improving impact toughness of Ti-containing high-strength steel in thickness larger than or equal to 10mm

An impact toughness, high-strength steel technology is applied in the field of improving the impact toughness of titanium-containing high-strength steels with a thickness of ≥10mm, which can solve the problems of increasing the cost of Ti-strengthened high-strength steel alloys, and achieve the effect of low alloy costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

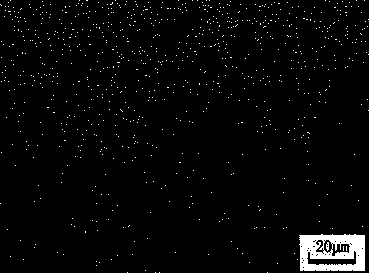

Image

Examples

Embodiment 1

[0035] Its steps:

[0036] 1) Applicable conditions of this method: the composition of Example 1 (S460MC) is shown in Table 1, and the superheat of molten steel is 11.5°C;

[0037] Table 1 Chemical composition of Example 1 (wt%)

[0038] serial number C Si mn P S Ti N als Example 1 0.076 0.025 0.88 0.006 0.0041 0.086 0.0036 0.034

[0039] 2) The slab is heated according to different heating rates: the soaking temperature of the slab is controlled at 1188~1196°C, of which: the heating rate from room temperature to 549.5°C is 11.5°C / s, and the heating rate from 550~949.8°C is 8.3°C / s Carry out heating and heating, from 950 to 1196 ° C at a heating rate of 4.3 ° C / s for heating, soaking for 15 minutes; the total heating time is 165 minutes;

[0040] 3) Rough rolling is carried out, the rolling pass is 5 passes, and the average reduction rate of the first three passes is 17.5%, and the reduction rate of the last two passes is 33% and 31...

Embodiment 2

[0046] Its steps:

[0047]1) Applicable conditions of this method: the composition of Example 2 (S500MC) is shown in Table 2, and the superheat of molten steel is 12°C;

[0048] Table 2 Chemical composition of Example 2 (wt%)

[0049] serial number C Si mn P S Ti N als Example 1 0.065 0.23 0.98 0.010 0.0021 0.116 0.0028 0.039

[0050] 2) The casting slab is heated according to different heating rates: the soaking temperature of the casting slab is controlled at 1203~1209°C, of which: the heating rate from room temperature to 549.8°C is 13.0°C / s, and the heating rate of 550~949.5°C is 8.2°C / s Carry out heating and heating, from 950 to 1209°C at a heating rate of 5.0°C / s; soak for 20 minutes, and the total heating time is 160 minutes;

[0051] 3) Carry out rough rolling, the rolling pass is 5 passes, and the average reduction rate of the first three passes is 20%, and the reduction rate of the last two passes is 32% and 35% respectively...

Embodiment 3

[0057] Its steps:

[0058] 1) Applicable conditions of this method: the composition of Example 3 (S500MC) is shown in Table 3, and the superheat of molten steel is 14°C;

[0059] Table 3 Chemical composition (wt%) of Example 3

[0060] serial number C Si mn P S Ti N als Example 1 0.066 0.25 1.13 0.008 0.0035 0.110 0.0030 0.026

[0061] 2) After smelting and continuous casting into slabs, heat the slabs according to different heating rates: control the soaking temperature of the slabs at 1191~1197°C, of which: the heating rate from room temperature to 549.7°C is 12.6°C / s, 550~949.6 The temperature rise rate is 8.5°C / s, and the temperature rise rate is 4.8°C / s from 950 to 1197°C; the soaking time is 20 minutes, and the total heating time is 158 minutes;

[0062] 3) Carry out rough rolling, the rolling pass is 5 passes, and the average reduction ratio of the first three passes is 23%, and the reduction ratio of the last two passes is 35%...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com