Grid-type gas distribution device for MOCVD (metal-organic chemical vapor deposition) reactor

A gas distribution device and gas distribution technology, applied in the direction of gaseous chemical plating, metal material coating process, coating, etc., can solve the problems of excessive deposits and strong pre-reaction, so as to prolong the cleaning cycle, reduce waste, Reduces the effect of deposition reactants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

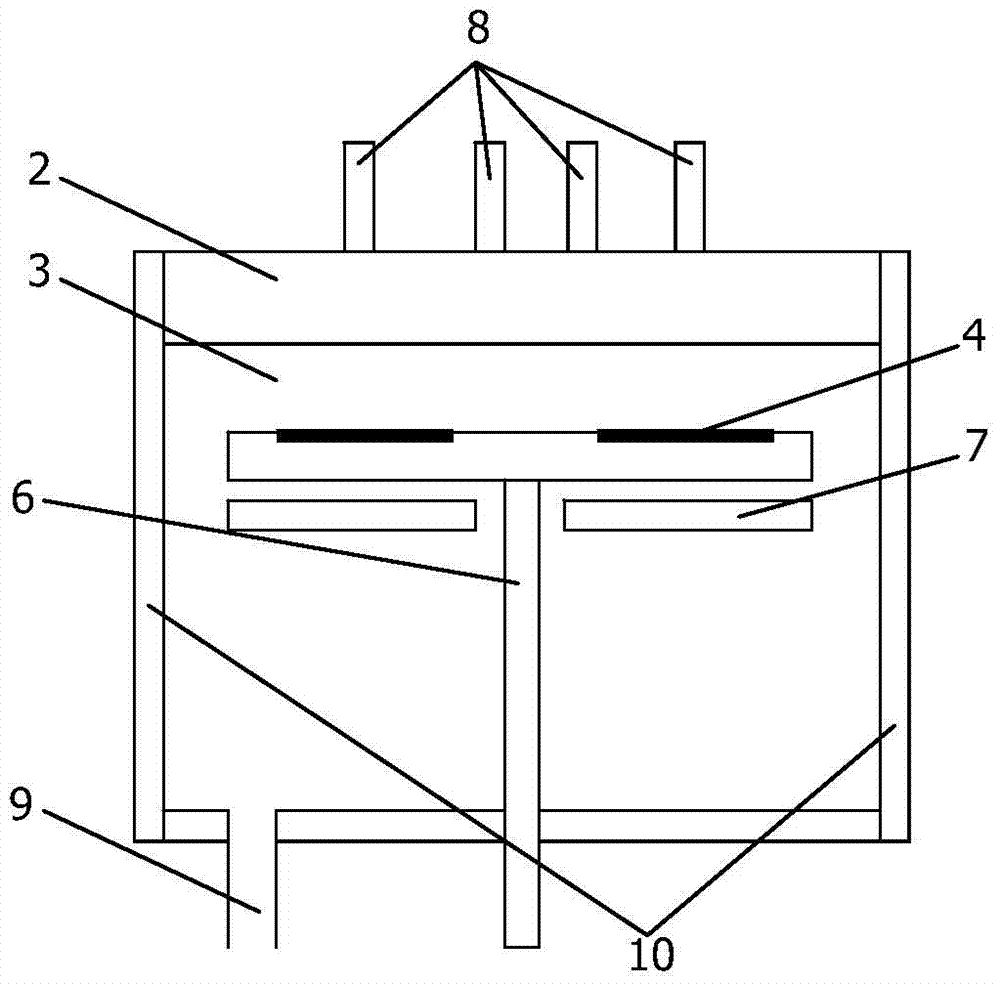

[0043] figure 1 Shown is a schematic diagram of a currently widely used MOCVD reaction chamber 1 . The first precursor gas, the second precursor gas, and the carrier gas enter the reaction chamber 3 surrounded by the reaction chamber wall 10 through the connecting pipe 8 located above an embodiment of the present invention (gas distribution device 2), and the reactant source material After entering the reaction chamber through the gas distribution device 2, it reaches the wafer 4 placed on the upper surface of the loading tray 5 through processes such as diffusion and transportation, and the wafer 4 rises to the process temperature under the action of the heating device 7 located under the loading tray 5 The reactant source material is deposited on the surface of the wafer 4 through a series of complex physical and chemical reactions to obtain the required film material, and the reaction waste is discharged from the reaction chamber through the tail gas outlet 9. Generally, d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com