Artificial lawn and fabrication process thereof

A technology of artificial turf and manufacturing process, which is applied in the direction of lawn growth, sustainable manufacturing/processing, gardening, etc. It can solve the problems of immovability and disassembly, engineering construction waste, and excessive engineering waste, so as to facilitate transportation and laying, save Materials and costs, the effect of making materials simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

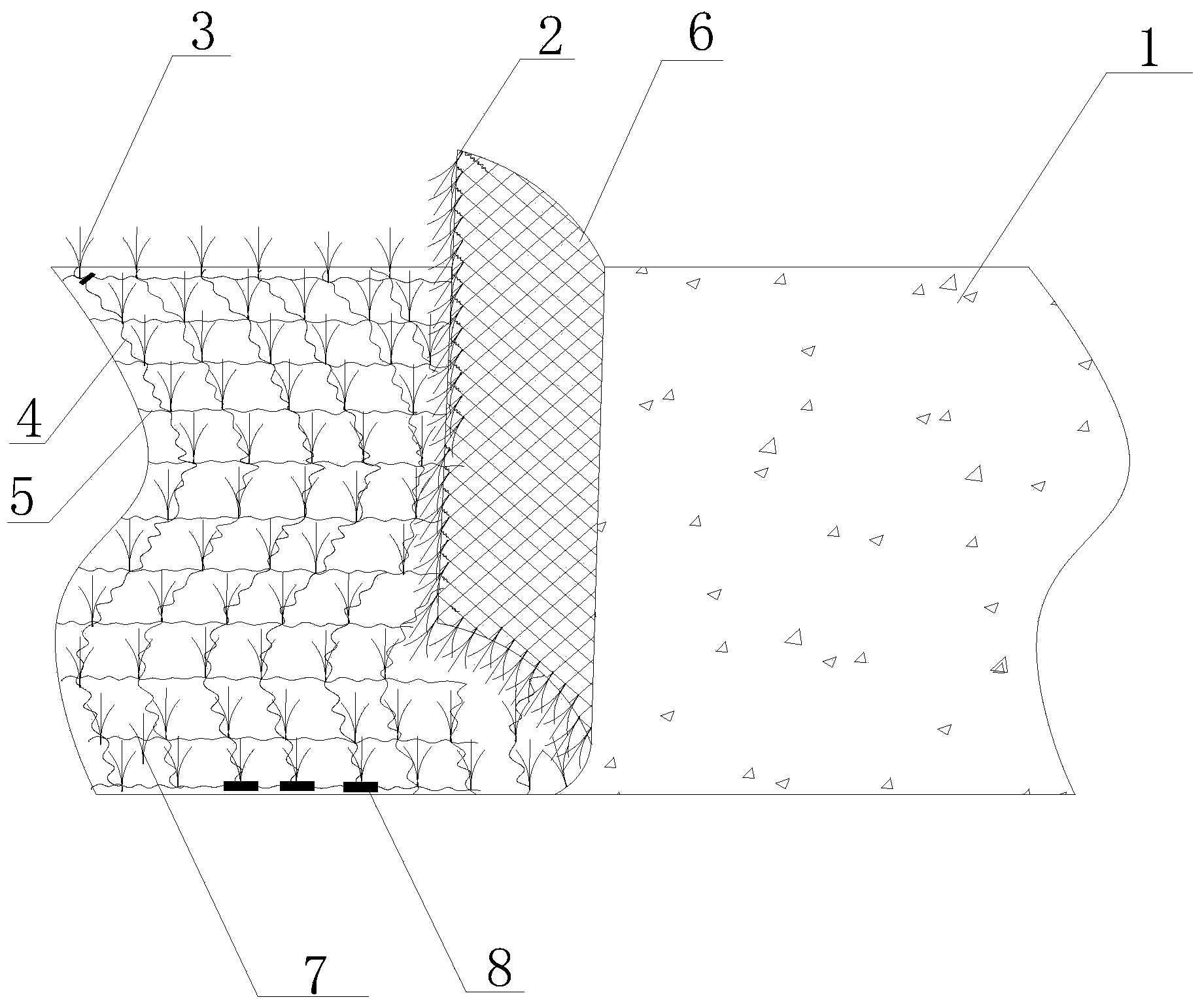

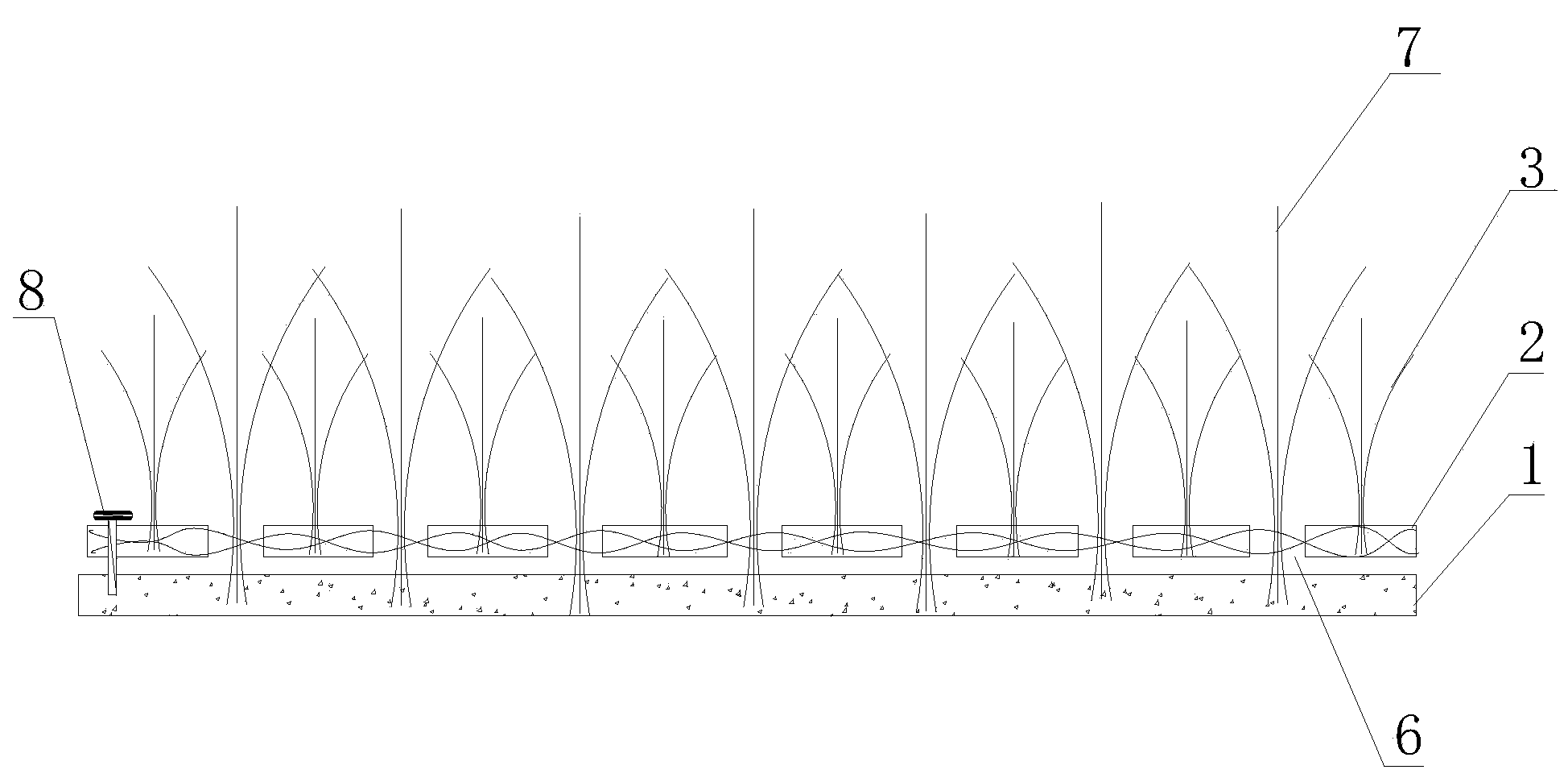

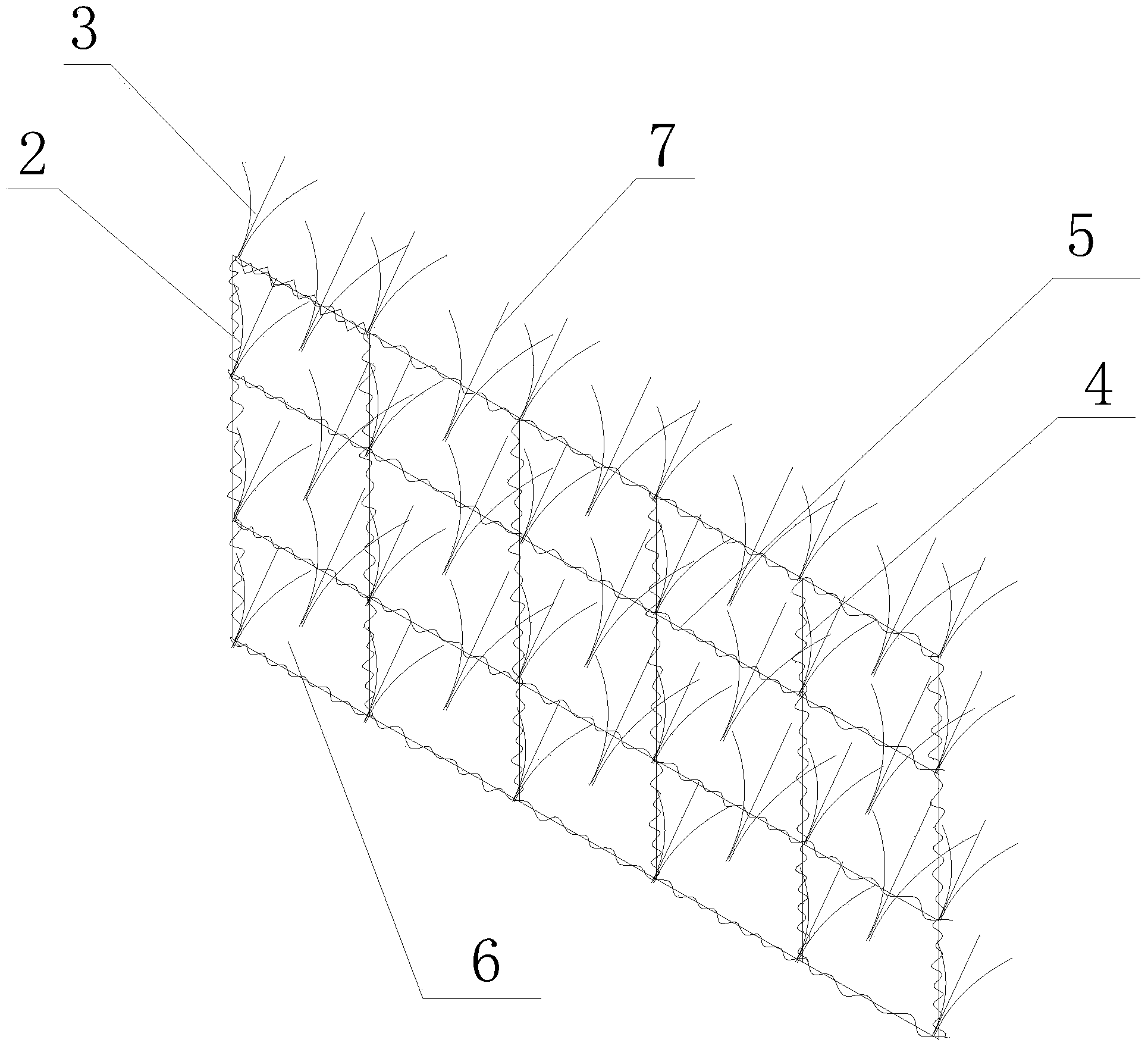

[0031] Example 1, such as figure 1 As shown, a kind of artificial turf described in the embodiment of the present invention comprises a soil base 1, a warp-knitted grid 2 laid above the soil base and fiber grass tufts 3 woven on the warp-knitted grid. The warp-knitted grid is composed of A grid structure composed of interweaving warp threads 4 and weft threads 5. Natural grass 7 is inserted into the grid 6 formed by the warp-knitted grid, and the grass roots of the natural grass are planted in the soil base.

[0032]Wherein, the warp thread and the weft thread are all grass silk bundles woven and twisted by fiber grass silk, and the grass roots of the fiber grass clusters are woven in the grass silk bundle.

[0033] The artificial turf has changed the structure of the artificial turf in the prior art, and the warp-knitted grid woven by the fiber artificial turf replaces the bottom of the existing artificial turf, and the present invention uses the fiber grass in the process of...

Embodiment 2

[0036] Example 2, such as Figure 1-3 As shown, a kind of artificial turf described in the embodiment of the present invention comprises a soil base layer, a warp-knitted grid laid above the soil base layer, and fiber grass clusters woven on the warp-knitted grid. Interwoven grid structure, natural grass is inserted into the grid formed by the warp-knitted grid, and the grass roots of the natural grass are planted in the soil base.

[0037] Wherein, the warp thread and the weft thread are all grass silk bundles woven and twisted by fiber grass silk, and the grass roots of the fiber grass clusters are woven in the grass silk bundle.

[0038] Further, the warp-knitted grid is fixed to the soil base through the ground needles 8, the ground needles pass through the warp-knitted grid, and the bottom ends of the ground needles are inserted into the soil base. In this technical solution, the ground needles are used to fix the position of the warp-knitted grid to prevent the warp-kni...

Embodiment 3

[0040] Example 3, such as Figure 4 As shown, in the embodiment of the present invention also provides a kind of artificial turf manufacturing process, this process comprises the following steps:

[0041] Step ①: producing fiber grass;

[0042] Step ②: Arrange a number of grass fibers side by side and weave them into a twist-like grass wire bundle, and weave a number of grass wire bundles into a warp-knitted grid;

[0043] Step ③: Build a soil base on the site;

[0044] Step ④: laying the woven warp-knitted grid above the soil base;

[0045] Step ⑤: Insert or plant natural grass in the grid of the warp-knitted grid.

[0046] In the technical solution, in the further step ①, the fiber grass tufts are produced while the fiber grass silks are produced, and the fiber grass tufts are composed of at least two fiber grass silks connected. In the technical solution, in the further step ②, while weaving the grass wire bundle, weave the grass roots of the fiber grass tufts into the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com