Design and application method of lifting frame of continuous truss column top hinged structure

An application method and a lifting frame technology, which are applied in building structure, building material processing, construction, etc., can solve the problems of poor operability and economy, and large amount of measures, and achieve the advantages of convenient construction, simple form, and integrity assurance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

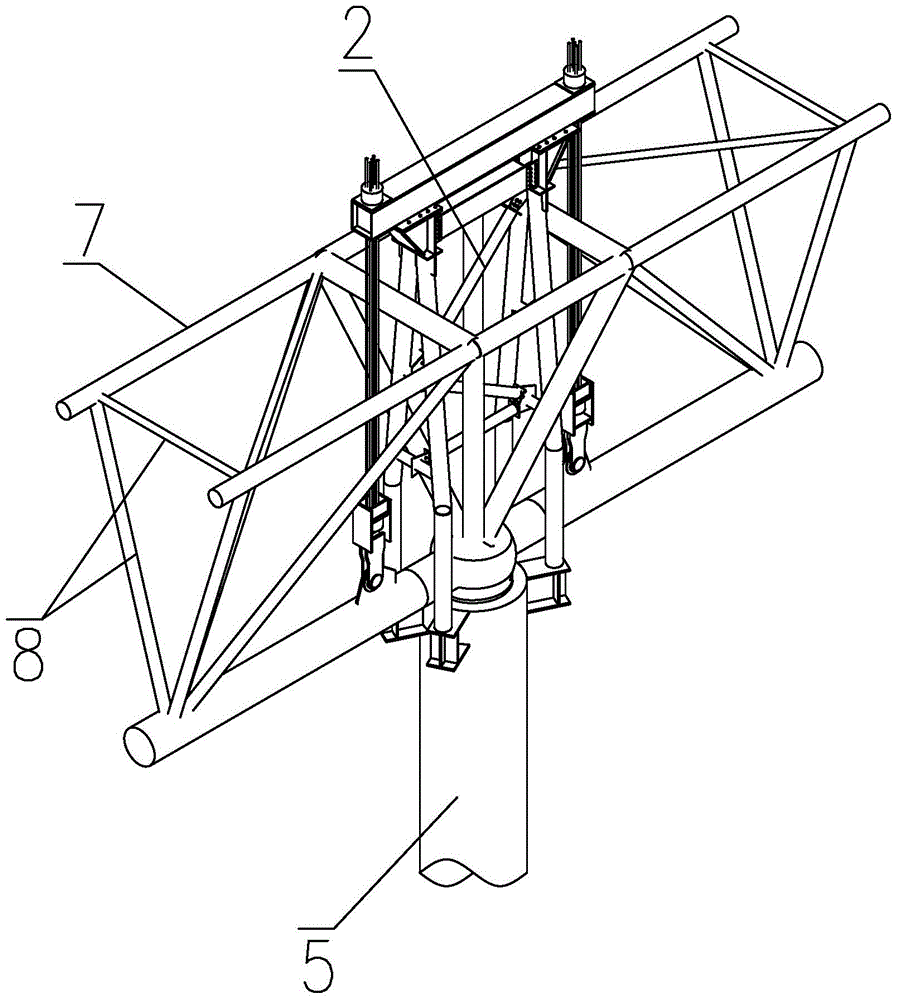

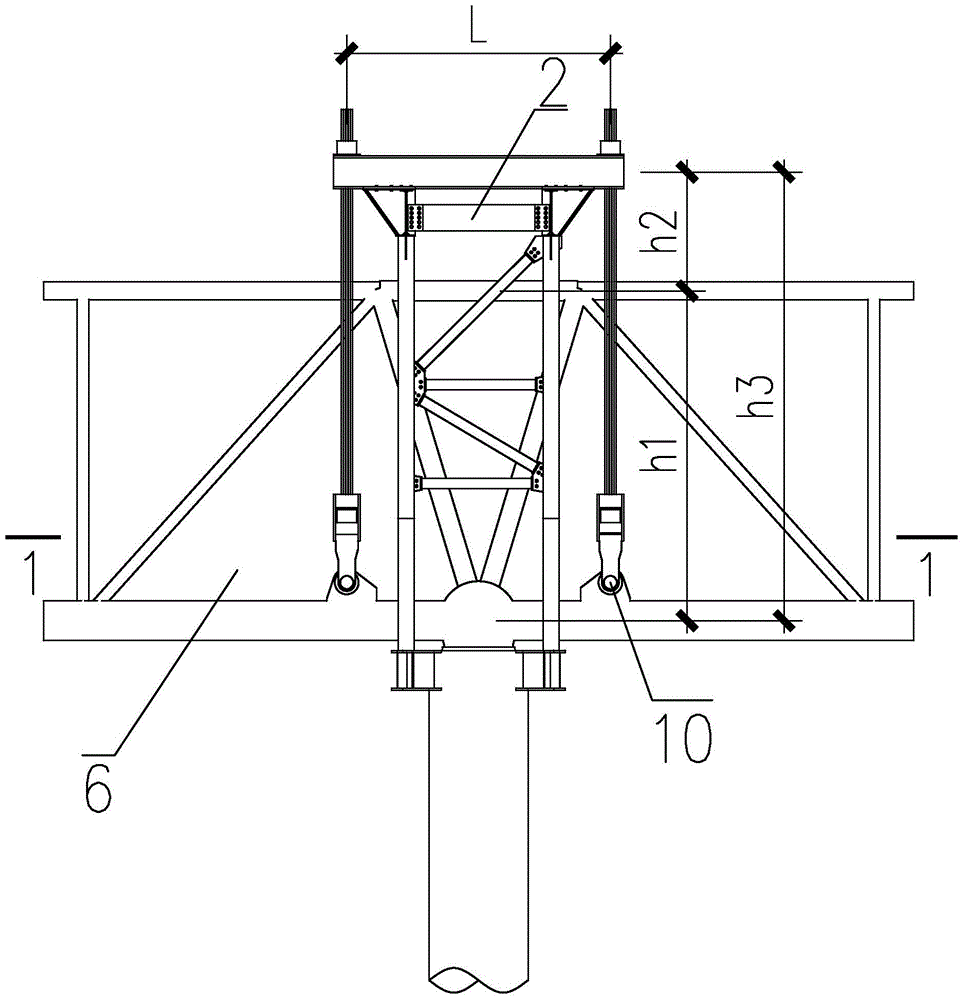

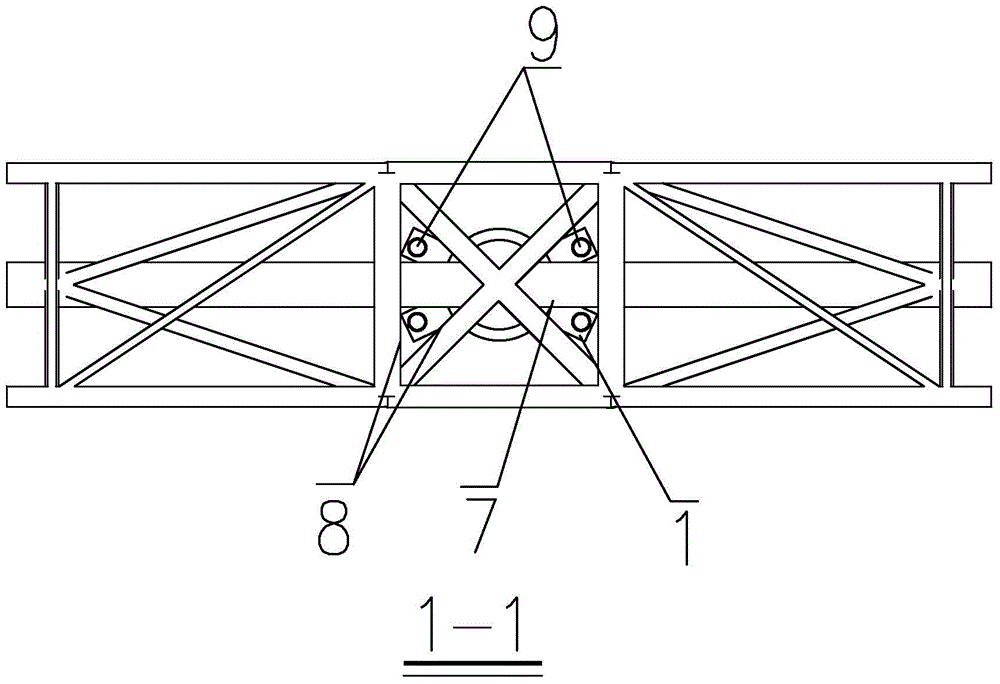

[0031] Next, the present invention will be described in further detail in conjunction with the accompanying drawings.

[0032] Such as Figure 1-7 The shown design and application method of the hoisting frame of a continuous truss column top hinged structure is one of the embodiments of the present invention. The total construction area is 99,200 square meters, with two floors above ground, one floor underground, and interlayers in some places. The main structure is a reinforced concrete frame structure plus a two-way steel truss structure, the supporting structure is a steel reinforced concrete column, and the top of the column is equipped with an anti-seismic spherical hinge support. The steel roof adopts a two-way orthogonal truss structure. The span of the three-span continuous truss is 40m+66m+40m, and the cantilever length on both sides is 25m.

[0033] The steel roof adopts the installation scheme of "partition assembly and partition elevation". The assembly position...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com