Glass fiber wound reinforced polyurethane resin conical electric pole and production method thereof

A polyurethane resin, winding reinforcement technology, applied in chemical instruments and methods, synthetic resin layered products, glass/slag layered products, etc., can solve the problems of low production efficiency, unsatisfactory fiber laying angle, material waste, etc. Achieve the effect of improving utilization rate, speeding up marketization process, and reducing manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

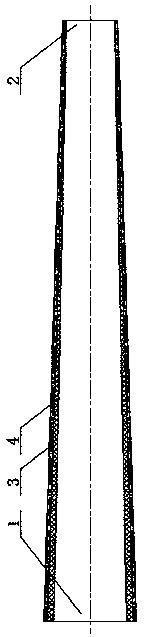

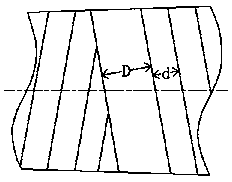

[0023] Such as figure 1 and figure 2 As shown, it is a schematic structural diagram of the glass fiber winding reinforced polyurethane resin tapered pole described in this embodiment. The glass fiber winding reinforced polyurethane resin tapered electric pole in this embodiment includes: a root 1 and a tip 2, the outer diameter of the root 1 is greater than the outer diameter of the tip 2, and the wall thickness of the root 1 is greater than that of the tip 2. The wall thickness of the tip portion 2; it also includes an equal-thickness layer 3 on the outside and a thickness gradient layer 4 on the inside, and the equal-thickness layer 3 is an alkali-free glass fiber axial fabric or an alkali-free glass fiber multi-directional fabric winding The thickness gradient layer 4 is formed by direct yarn winding of alkali-free glass fibers. Preferably, as figure 2 As shown, the non-alkali glass fiber axial fabric or the non-alkali glass fiber multi-directional fabric of the equal ...

specific Embodiment 2

[0031] Such as figure 1 and figure 2 As shown, it is a schematic structural diagram of the glass fiber winding reinforced polyurethane resin tapered pole described in this embodiment. The glass fiber winding reinforced polyurethane resin tapered electric pole in this embodiment includes: a root 1 and a tip 2, the outer diameter of the root 1 is greater than the outer diameter of the tip 2, and the wall thickness of the root 1 is greater than that of the tip 2. The wall thickness of the tip portion 2; it also includes an equal-thickness layer 3 on the outside and a thickness gradient layer 4 on the inside, and the equal-thickness layer 3 is an alkali-free glass fiber axial fabric or an alkali-free glass fiber multi-directional fabric winding The thickness gradient layer 4 is formed by winding an alkali-free glass fiber axial fabric or an alkali-free glass fiber multi-directional fabric. Preferably, as figure 2 As shown, the non-alkali glass fiber axial fabric or the non-al...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com