High-efficiency ore drawing process system for ore draw shaft

A process system and chute technology, which are applied in the field of chute efficient ore drawing process system and ore chute efficient ore drawing process system, can solve the problems of ore clogging and easy clogging, and achieve high efficiency, low cost, easy construction or manual installation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

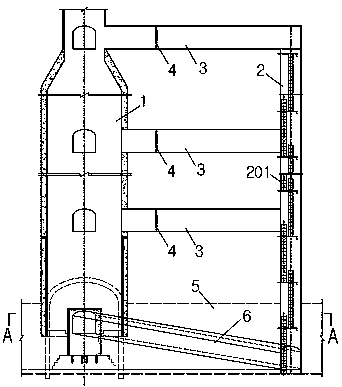

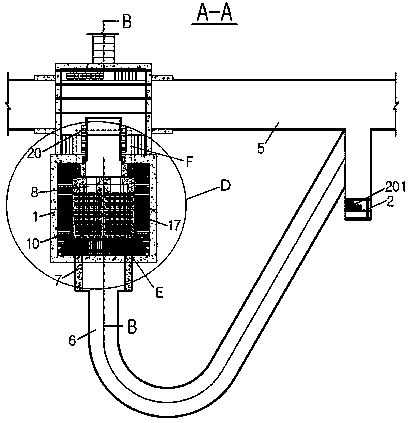

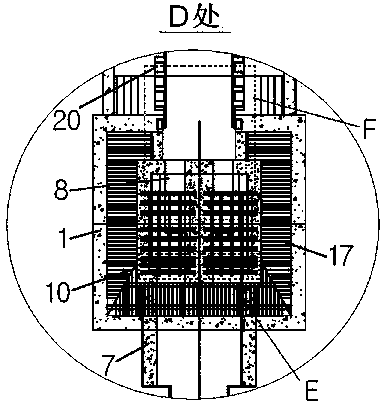

[0018] The present invention aims at the easy ore blockage phenomenon of the existing chute ore drawing system, and designs an ore chute high-efficiency ore drawing process system. One is to design 2 to 3 sections of inspection level lane 3 on the chute 1, and the inspection level way 3 is placed on the ore slide. The blind areas on the side and the opposite side are connected with the chute 1, the inspection level lane 3 of each section is respectively connected with the pedestrian / ventilation patio 2, and the bottom of the pedestrian / ventilation patio 2 is connected with the transportation lane 5, and an inspection level lane 3 is installed near the chute 1. Fan airtight door 4, airtight door 4 cuts off chute 1 and pedestrian / ventilation patio 2, the dust that slides ore can not return to pedestrian / ventilation patio 2. When the chute 1 is blocked by ore, the technicians go up to the inspection level 3 through the pedestrian / ventilation patio 2, open the airtight door 4, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com