Outer cup rotary axial eddy current damper

An eddy current damper and eddy current damping technology, which is applied in the direction of springs/shock absorbers, springs, magnetic springs, etc., can solve problems such as hindering the application of eddy current damping, low energy consumption density of eddy current damping, and difficulty in meeting seismic requirements. , to achieve the effect of increasing the magnetic field strength and improving the shock absorption control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

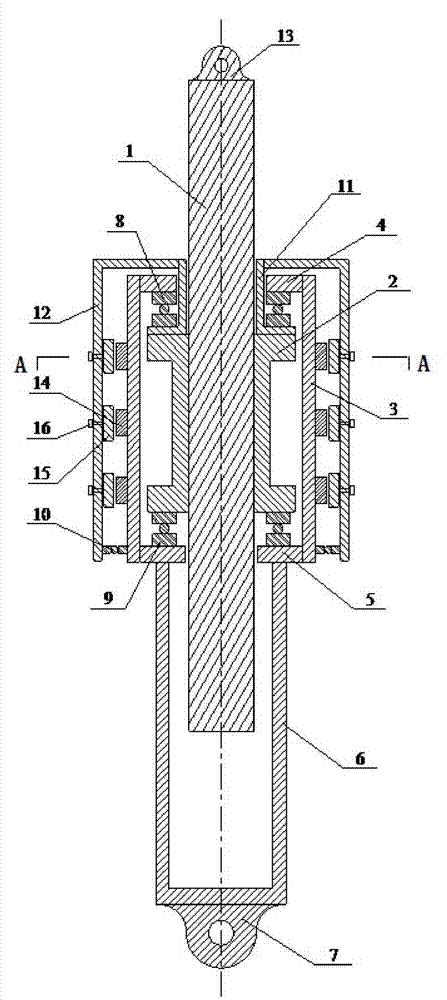

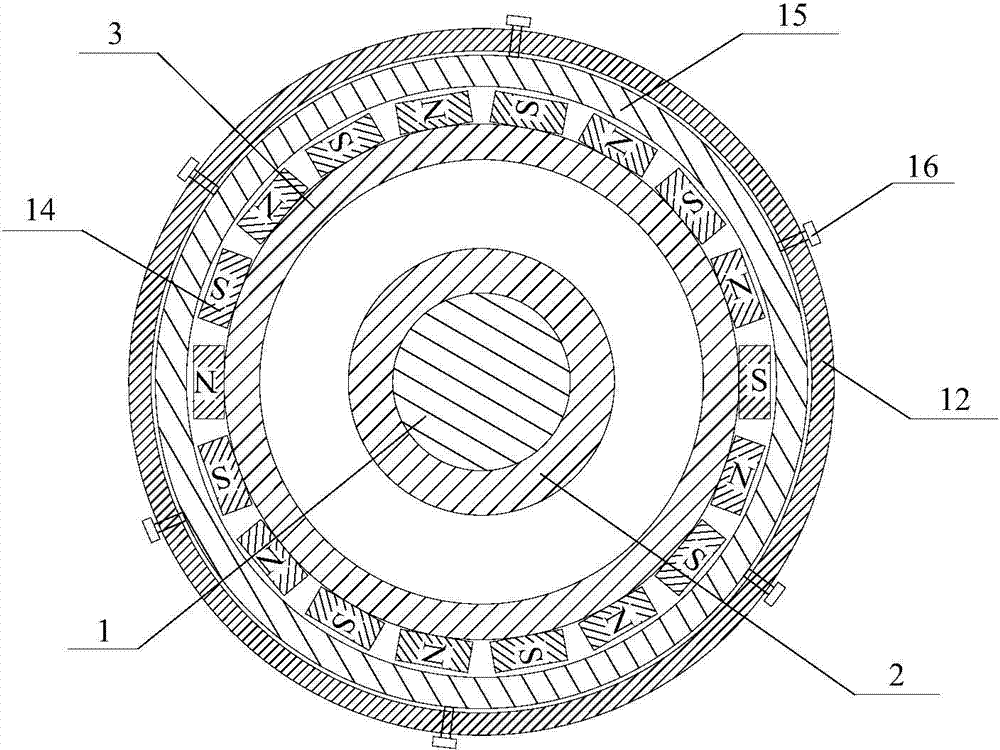

[0031] Such as figure 1As shown, an outer cup rotating axial eddy current damper includes a transmission assembly and an eddy current damping generator. The transmission assembly includes a screw drive pair and a stator and a rotor made of magnetically conductive materials; the screw drive pair It includes a screw rod 1 and a nut 2 set on the screw rod 1; the stator 3 is a section of circular tube with upper and lower openings, the upper opening of the stator 3 is installed with an upper flange 4, and the lower opening of the stator 3 is installed with a lower flange 5, The screw 1 passes through the center hole of the upper flange 4 and the center hole of the lower flange 5 in sequence, and the nut 2 is placed inside the stator 3, and the upper end surface of the nut 2 passes through the upper thrust bearing 8 and the upper flange 4. The bottom surface is connected, and the lower end surface of the nut 2 is connected to the top surface of the lower flange 5 through the lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com