A fast heat exchange water storage tank

A water storage tank, fast technology, applied in the direction of heat exchangers, indirect heat exchangers, lighting and heating equipment, etc., can solve the problems of no storage, low heat exchange efficiency, storage of water, etc., to achieve fast heat exchange, exchange Good thermal effect and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

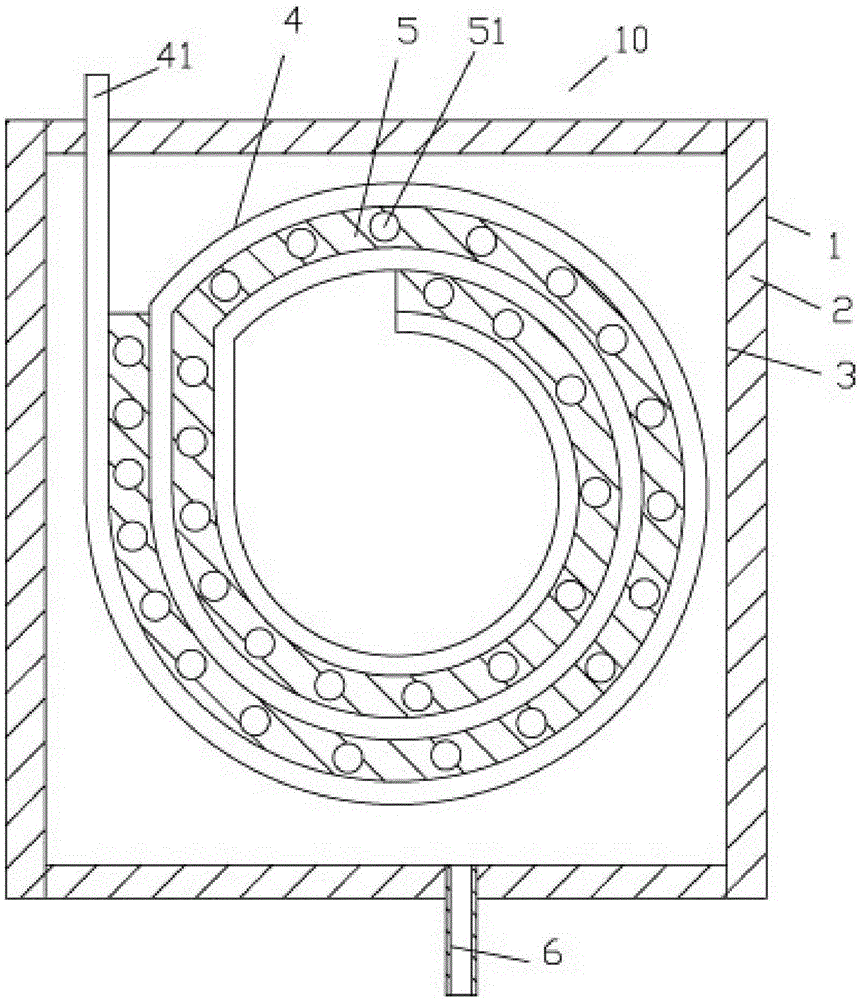

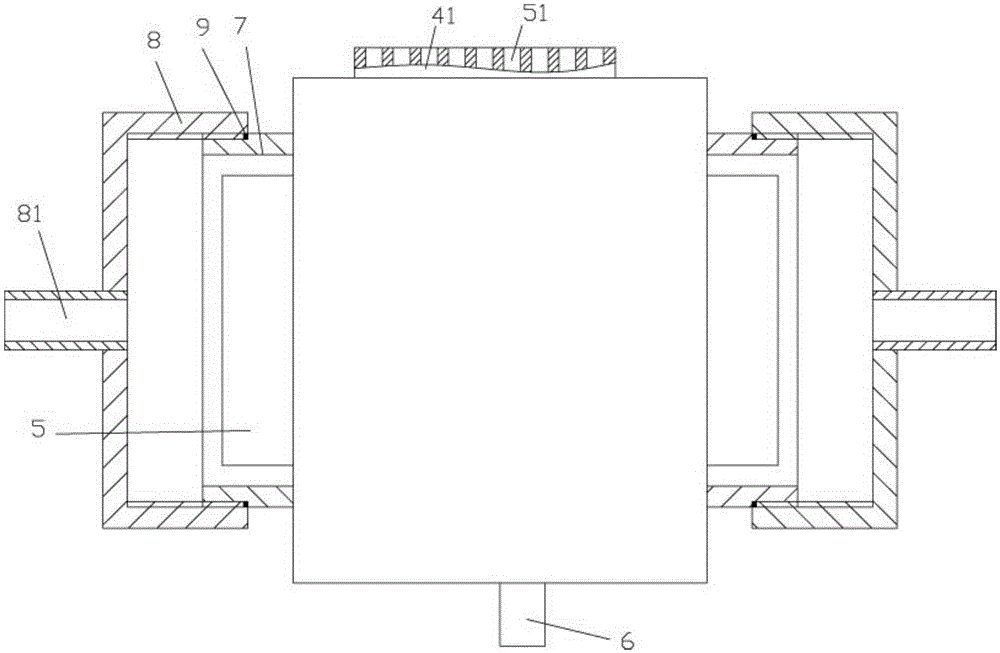

[0012] Examples, see e.g. Figure 1 to Figure 2 As shown, a rapid heat exchange water storage tank includes a box body 10, and the box body 10 includes an outer shell 1, a middle insulation layer 2 and an inner tank 3, and the middle insulation layer 2 is between the outer shell 1 and the inner tank 3, The water liquid flat tube 4 is serpentine and coiled and fixed in the liner 3, the water inlet end 41 of the water liquid flat tube 4 protrudes from the upper top surface of the box body 10, and the horizontal flow flat tube 5 is serpentine and coiled so it is fixed on the In the liner 3, the horizontal flow flat tube 5 and the water liquid flat tube 4 are inserted and sleeved together, the side wall of the horizontal flow flat tube 5 is attached to the side wall of the water liquid flat tube 4, and one end of the horizontal flow flat tube 5 extends Out of the front side wall of the box body 10 , the other end stretches out from the back side wall of the box body 10 , the botto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com