Vertical condenser

A condenser and vertical technology, which is applied in the field of new high-efficiency vertical condensers, can solve the problems of reducing heat exchange efficiency, achieve high heat exchange efficiency, reduce gas pressure drop, and save equipment footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

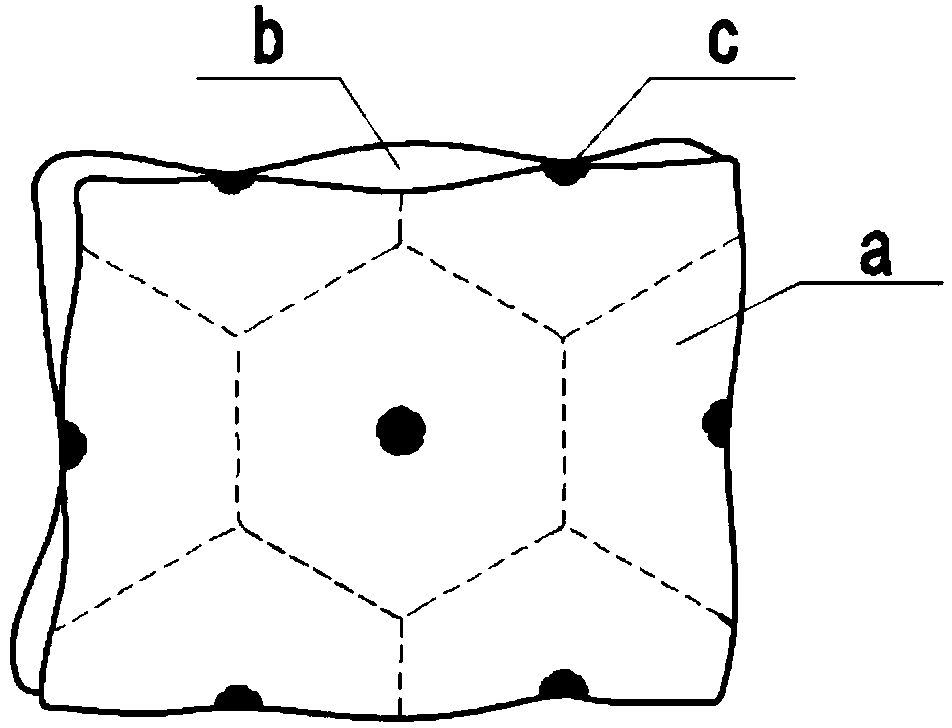

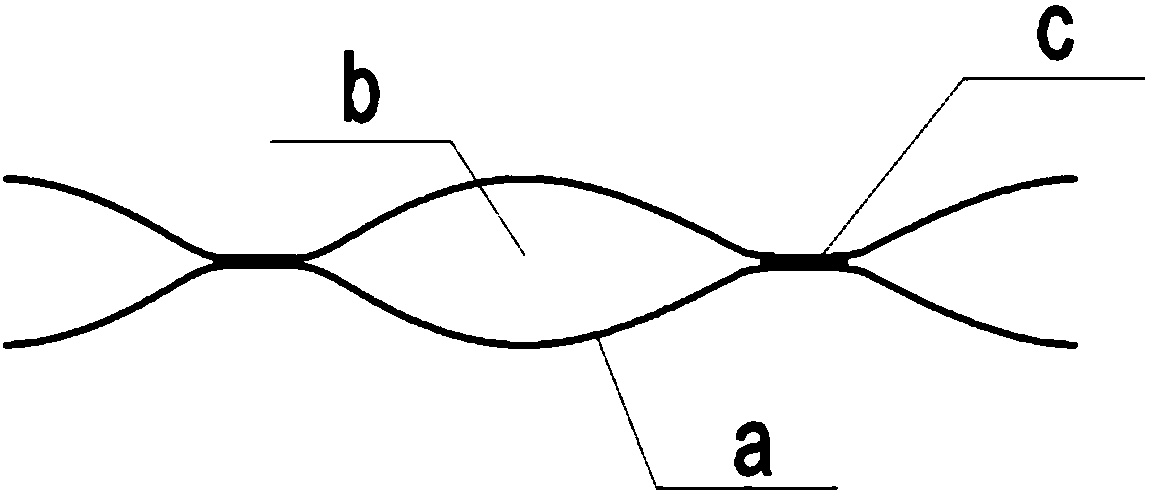

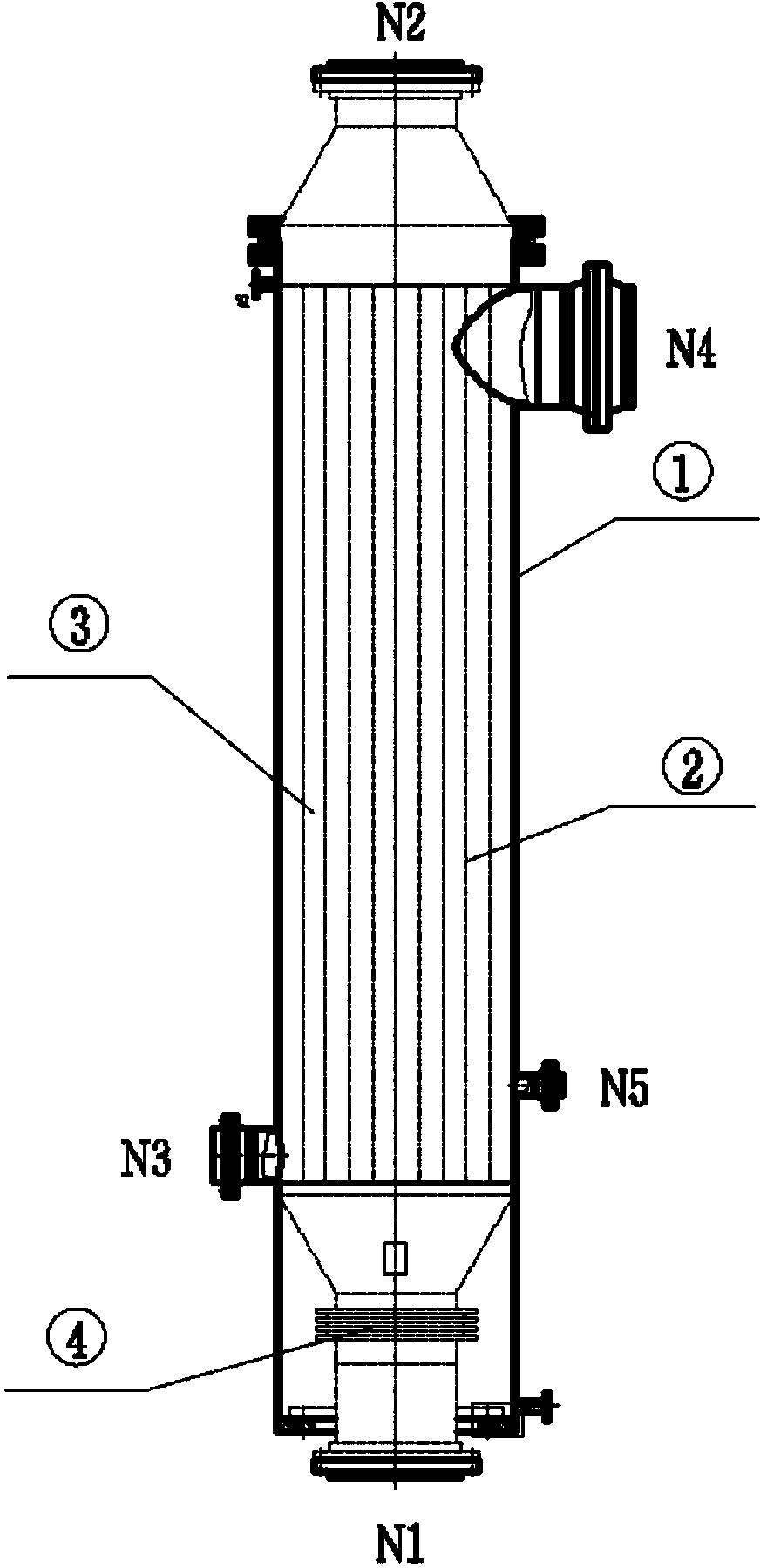

[0041] like Figure 1~3 As shown, a vertical condenser, the condenser includes a pair of heat exchange plates ②, an expansion joint ④ and a shell ①, the heat exchange plate pair is formed by two metal plates through multi-point welding and can be replaced As for the components of the plate-side cavity b through which the thermal fluid circulates, multiple pairs of heat-exchanging plate pairs are installed in the shell, and a shell-side cavity ③ is formed between each pair of heat-exchanging plate pairs and between the shell and the shell. A plurality of welding contacts are evenly arranged on the heat exchange plate to form a pillow heat exchanger, such as Figure 1~2 shown. The plurality of welding contacts are arranged in a staggered manner, and the contact density in common working conditions is 200-5000 / m 2 , The contact spacing is generally 20-100mm, and it can also be adjusted up and down under some special working conditions, which can be achieved in the manufacturing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com