Inner heat exchange-type bubble column reactor

A bubble tower and reactor technology, applied in the field of new high-efficiency internal heat exchange bubble tower reactor, can solve the problems of unfavorable industrial scale-up, accelerated fluid turbulence, large gas phase pressure drop, etc., and achieve increased reaction selectivity , compact structure, reducing the effect of liquid back-mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

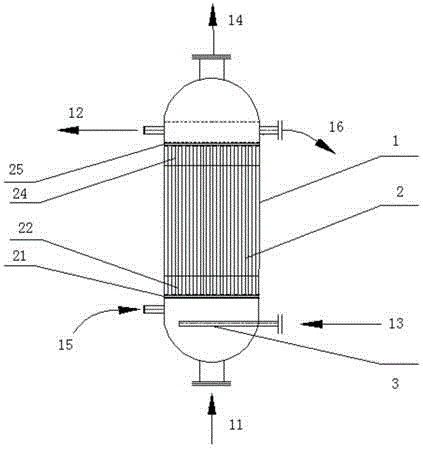

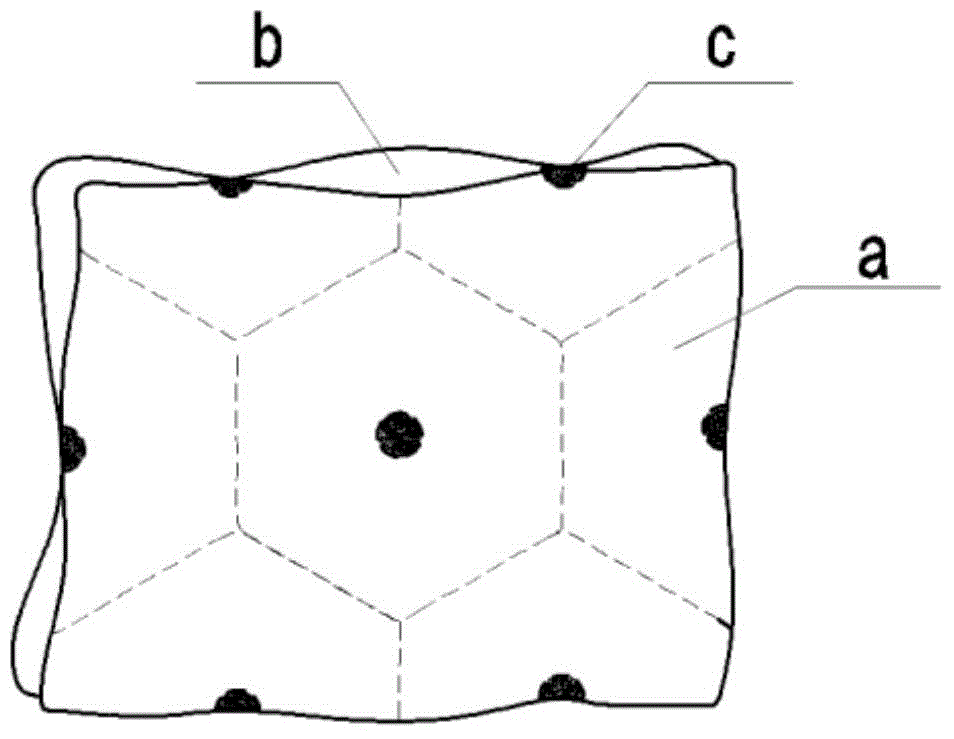

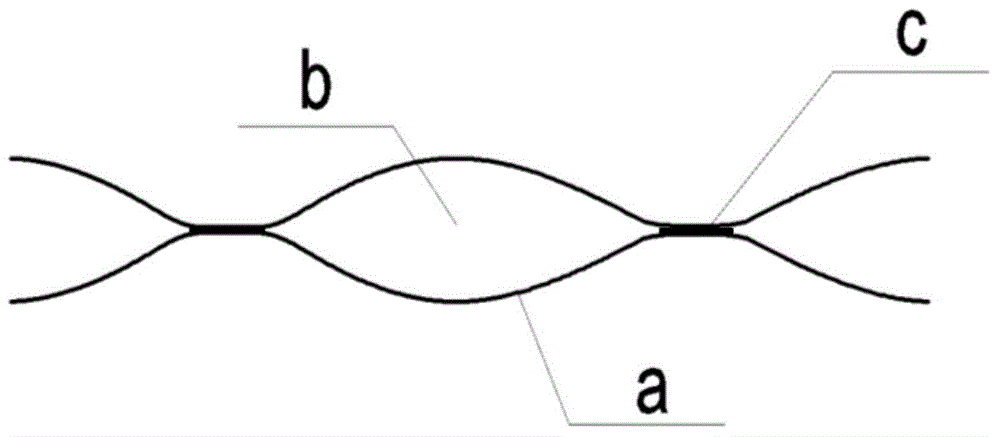

[0034] Such as Figure 1~4 As shown, an internal heat exchange bubble column reactor is composed of figure 1 , the heat exchange element group in 2 is skillfully combined with the conventional bubble column to form a image 3 The internal heat exchange bubble column reactor shown. The reactor includes a bubble column, a gas distributor and an internal heat exchange element, and the bubble column includes a cylinder 1 and a reaction liquid inlet 11 arranged on the cylinder, a reaction liquid outlet 12, and a reaction gas inlet 13, Reaction gas outlet 14 , heat exchange fluid inlet 15 , heat exchange fluid outlet 16 . The reaction gas inlet 13 is arranged at the bottom of the cylinder body 1 and flows upward through the gas distributor 3. The reaction liquid inlet 11 is arranged at the upper part of the cylinder body during countercurrent heat exchange, and the reaction liquid inlet 11 is arranged at the lower part of the cylinder body during downstream heat exchange. (In thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com